MBS Glass Machinery Insulating Glass Spacer Windows Spacer Double Edge Seal Warm Edge Spacer System 18 19MM

- Category: >>>

- Supplier: Panjin Xinghua Machinery Manufacturing Co. Ltd.

Share on (10000018103066):

Product Overview

Description

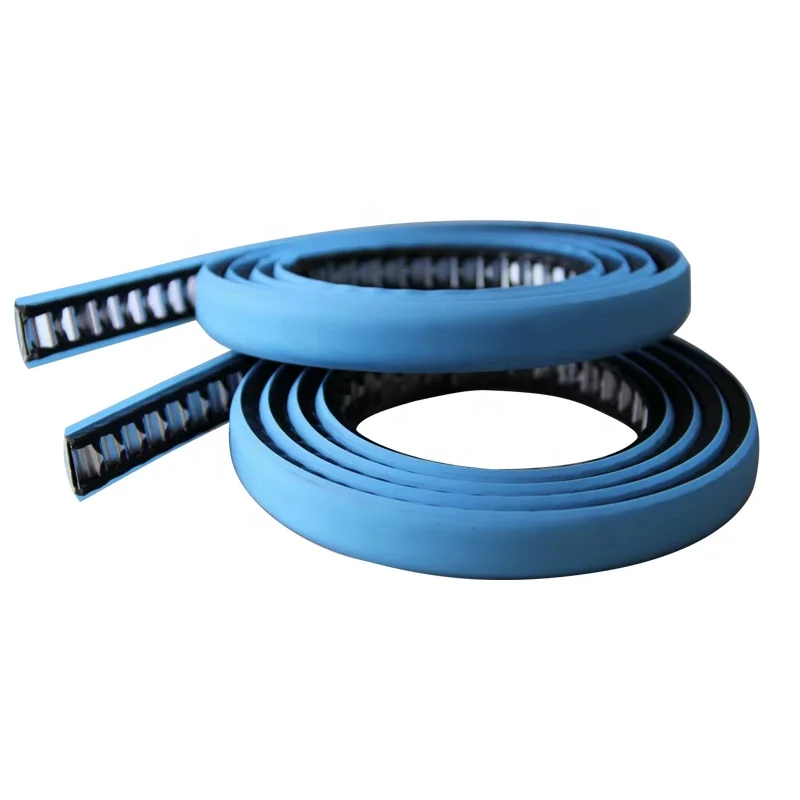

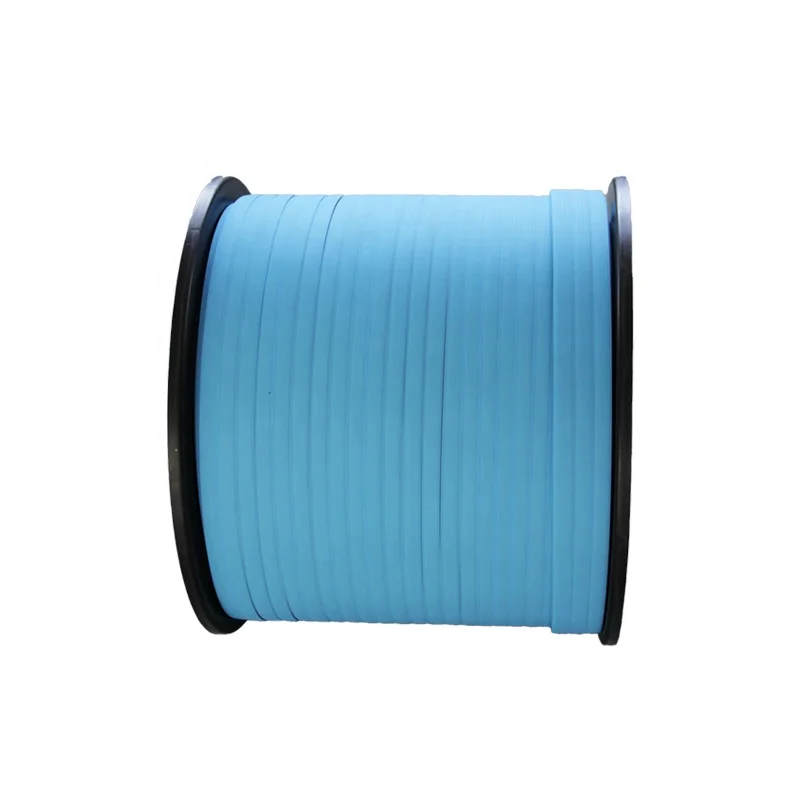

Item Name | MBS (Muti-layer Butyl Spacer ) |

Item Type | Flexible Sealing spacer for Insulating Glass |

Application | Glass windows, doors, refrigerators. |

Sizes | 6.5mm, 8mm, 9mm, 9.5mm, 10mm, 11mm, 12mm, 12.7mm, 14mm, 14.5mm, 16mm, 19mm, etc. |

Standard | ASTM E 2190.GBT 11944-2012.EN 1279-2. EN 12004:2007+A1:2012.ISO 9001.etc. |

Terms of Delivery | EXW, FOB, CFR, CIF, etc. |

Terms of Payment | T/T. D/P. Western Union. etc. |

Package | Standard sea/air/express delivery package, safety guaranteed. |

1. The continuous embossed support strip is built in, with only one interface, which avoids the deficiency of the four bending (corner) parts of the traditional aluminum partition strip and minimizes the moisture channel of the hollow

glass;

2. The high-quality desiccant is premixed in the surface adhesive, which can effectively ensure the stable and lasting performance of the desiccant. The standard test is -40 ℃ without condensation, and the limit test is -60 ℃ without

condensation;

3. The 6-8mm modified butyl rubber on the moisture transmission channel is more than 2 times that of the 3mm butyl rubber of the traditional aluminum separator, thus having the strongest moisture barrier performance;

4. Insensitivity to temperature reduces the convection formed by the air in the hollow glass cavity rising on the heated side and falling on the cold side, which can reduce convection by 4.5 times. The K value of hollow glass can be reduced by 0.2W/MK;

5. Successful one-step installation improves the work efficiency by 4 times compared with the traditional aluminum spacer method (the efficiency of special-shaped glass can be increased by more than 10 times);

6. It can be placed arbitrarily according to the geometric shape of the glass, thus greatly improving the production efficiency of special-shaped insulating glass;

7. The static storage time is shorter than that of traditional aluminum spacer hollow glass, which reduces the workshop area and improves the production efficiency.

8. The spacer is free of any volatile matter, clean and pollution-free, and meets the requirements of environmental protection.

glass;

2. The high-quality desiccant is premixed in the surface adhesive, which can effectively ensure the stable and lasting performance of the desiccant. The standard test is -40 ℃ without condensation, and the limit test is -60 ℃ without

condensation;

3. The 6-8mm modified butyl rubber on the moisture transmission channel is more than 2 times that of the 3mm butyl rubber of the traditional aluminum separator, thus having the strongest moisture barrier performance;

4. Insensitivity to temperature reduces the convection formed by the air in the hollow glass cavity rising on the heated side and falling on the cold side, which can reduce convection by 4.5 times. The K value of hollow glass can be reduced by 0.2W/MK;

5. Successful one-step installation improves the work efficiency by 4 times compared with the traditional aluminum spacer method (the efficiency of special-shaped glass can be increased by more than 10 times);

6. It can be placed arbitrarily according to the geometric shape of the glass, thus greatly improving the production efficiency of special-shaped insulating glass;

7. The static storage time is shorter than that of traditional aluminum spacer hollow glass, which reduces the workshop area and improves the production efficiency.

8. The spacer is free of any volatile matter, clean and pollution-free, and meets the requirements of environmental protection.

Products Description

Installation Instructions

Fully automatic insulating glass production line for warm edge spacers equipped with invention patent Spacer applicator applying spacers quickly and accurately by adopting multi-axis servo linkage and glass rotating technology to improving production efficiency.

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer with 20 years’ experience specialized in produce warm edge spacers for insulating glass.

Q: How long is the leading time?

A: Generally, 7-10 days after deposit, large order according to quantity.

Q: Do you provide free samples?

A: Sample is free, customer bear the freight cost.

Q: What is your terms of payment?

A: LCL, 100% TT in advance, FCL 30% T/T in advance, balance by copy of BL.

If you have another question, pls feel free to contact us.

A: We are professional manufacturer with 20 years’ experience specialized in produce warm edge spacers for insulating glass.

Q: How long is the leading time?

A: Generally, 7-10 days after deposit, large order according to quantity.

Q: Do you provide free samples?

A: Sample is free, customer bear the freight cost.

Q: What is your terms of payment?

A: LCL, 100% TT in advance, FCL 30% T/T in advance, balance by copy of BL.

If you have another question, pls feel free to contact us.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices