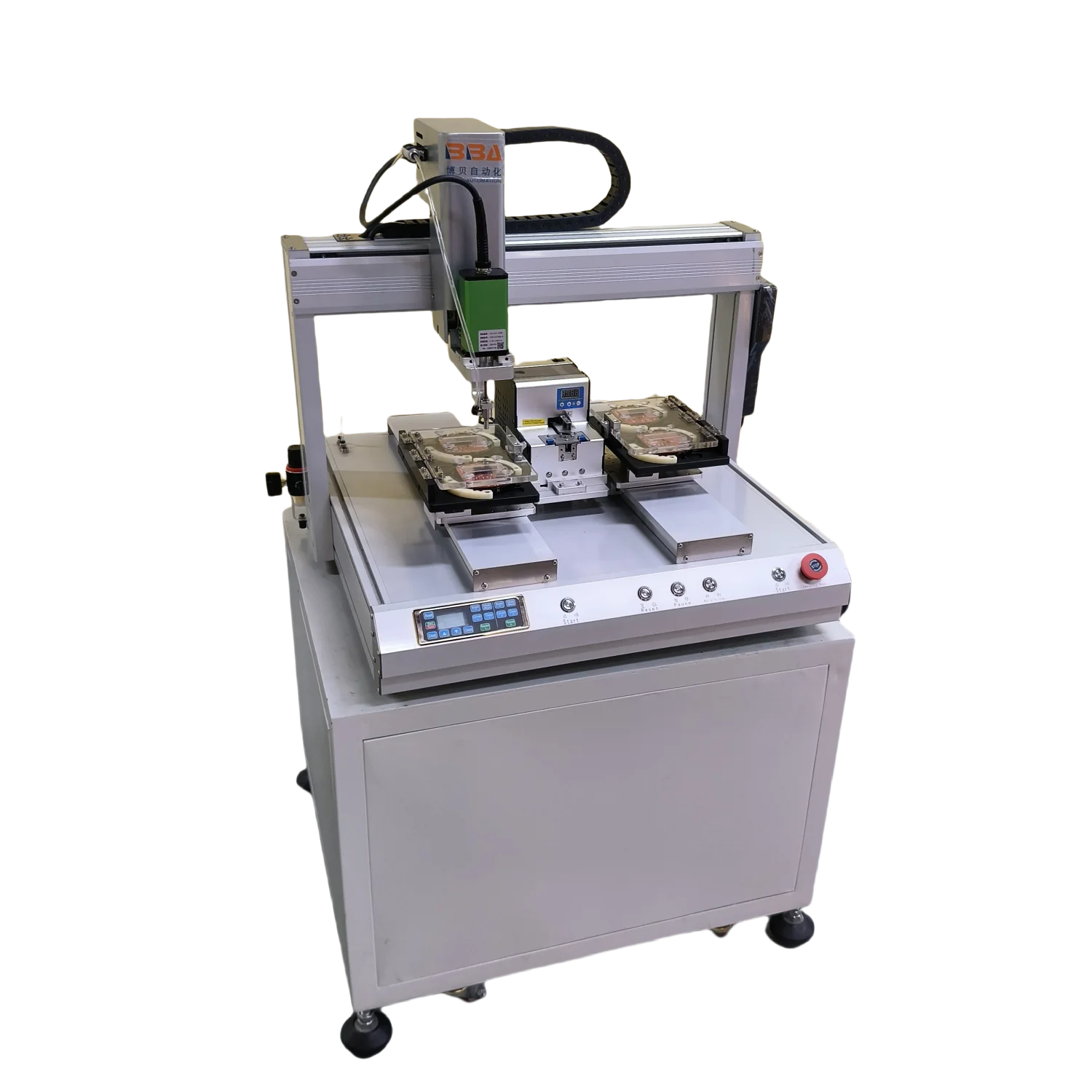

Servo motor screwdriver PCB robotic screw assembly Drilling/screwing machinery Auto feed tightening module screw feeder machine

- Category: >>>

- Supplier: Dongguan City Bobang Intelligent Technology Co. Ltd.

Share on (10000020114534):

Product Overview

Description

Servo motor screwdriver PCB robotic screw assembly Drilling/screwing machinery Auto feed tightening module screw feeder machine

* Increased Productivity: Automating the screw-driving process significantly boosts production speed.

* Consistent Quality: Ensures uniform tightening, reducing the risk of product defects.

* Labor Savings: Reduces the need for manual labor, lowering operational costs.

* Enhanced Safety: Minimizes the risk of repetitive strain injuries for workers.

* Torque Control: Allows for precise torque settings, preventing over-tightening or under-tightening.

Products Description

Machine external accessories

Detailed operating instructions & videos prepared to teach you step by step

Applicable screws

Customization available

Specification of screwing machine series

Model | BBA-331LS (Single Y platform) | BBA-5441LS (Double Y platform) | BBA-6441LS (Dual screw feeding system | CUSTOMIZED | |||||||||

Power supply | AC 110/220V 50/60HZ | ||||||||||||

Stroke | X | 300mm | X | 500mm | X | 600mm | To order | ||||||

Y | 300mm | Y1/Y2 | 400mm | Y1/Y2 | 400mm | ||||||||

Z | 100mm | Z | 100mm | Z | 100mm | ||||||||

Maximum load weight | 8KG(for work platform) | To order | |||||||||||

Screwdriver torque | 0.015~2.5N.m | More than 3.0N.m | |||||||||||

Moving speed | 10-800mm/s | ||||||||||||

Air pressure | 0.5~0.7Mpa | ||||||||||||

Position accuracy | ±0.02mm/axis | ||||||||||||

Program capacity | 999 groups/1000 points per group | ||||||||||||

Motor system | Micro Precision Stepping Motor | ||||||||||||

Transmission mode | Precision toothed belt+guide rail | ||||||||||||

Universal screws | M1-M8 | ||||||||||||

Control panel | Teaching pendant with display screen | ||||||||||||

Work efficiency | 1.2~1.5s/pcs | ||||||||||||

Work environment | Temperature: 5-40℃ Humidity: 20-90% | ||||||||||||

Weight | 100kg | 120kg | 150kg | To order | |||||||||

External machine Size (L*W*H) | 700*630*700mm | 820*730*700mm | 920*730*700mm | To order | |||||||||

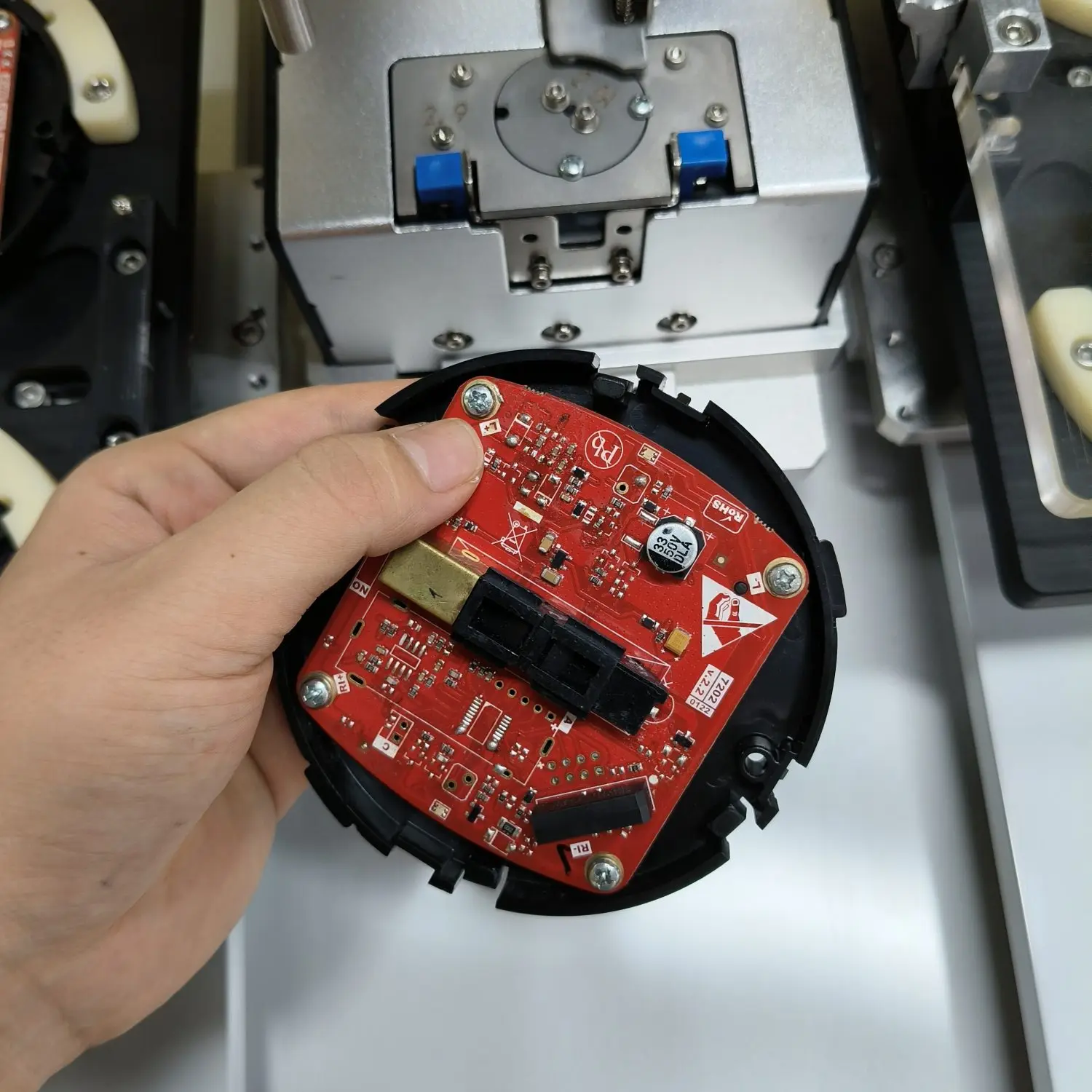

Customer case

Packing & Delivery

Company Profile

BBA machine headquartered in Guangdong, China. The manufacturer of automation machines. Main products are auto screw fastening machine, soldering machine, screw feeder machine, glue dispensing machine, PCB pin foot cutting machine and other non-standard automation equipment. BBA has accumulated rich engineering experience and master full set of core technology, can provide customers with full services from technology to equipment.In addition, we have a professional screw tightening technology, which is very helpful for mass production of screw locking, including special screw as the helico coiled screw and headless screws. In the automation solution providing and other fields have been unanimously recognized by users.

Over the past years, BBA have actively expanded the oversea market, with users all over America&Europe&Southeast Asia. The good atmosphere of the enterprise attracts a large number of outstanding talents, which makes the high-quality company with a highly cooperative professional team.

Over the past years, BBA have actively expanded the oversea market, with users all over America&Europe&Southeast Asia. The good atmosphere of the enterprise attracts a large number of outstanding talents, which makes the high-quality company with a highly cooperative professional team.

FAQ

Q: Why choose us? | ||||||||

A: We are factory and provide overall solutions for processing equipment. Our standard equipment is very complete,all are in stock and can be shipped quickly. We have our own equipment factory, which can fully customize equipment according to customer requirements, such as ordering different machine size& appearance and brand for agents. | ||||||||

Q: How can we guarantee quality? | ||||||||

A: We implement strict incoming materials inspection and 100% tests before shipment. Furthermore, our products have CE certificate. | ||||||||

Q: How long is your warranty? | ||||||||

A: Lasts for 12 months, lifetime technical support. | ||||||||

Q: Why need use automatic screw drilling machine? | ||||||||

A: Precise locking performance, high efficiency 1.2s/screw, save labor cost, raise productivity. | ||||||||

Q: What screw can be used for automatic screw fastening robot? | ||||||||

A: Applicable for M1~M8 screws/bolts/nuts | ||||||||

Q: What's the bulk order delivery time? | ||||||||

A: Order lead time will be 3~10 working days, depends on your product. | ||||||||

We Recommend

New Arrivals

New products from manufacturers at wholesale prices