Continuous Hand held Laser Cleaning Machine for Metals laser rust removal cleaning machines cleaning equipments

- Category: >>>

- Supplier: Hubei Feiyide Intelligent Equipment Co. Ltd.Hubei Ltd.

Share on (10000020702787):

Product Overview

Description

Laser Rust Remover Machine for Metal

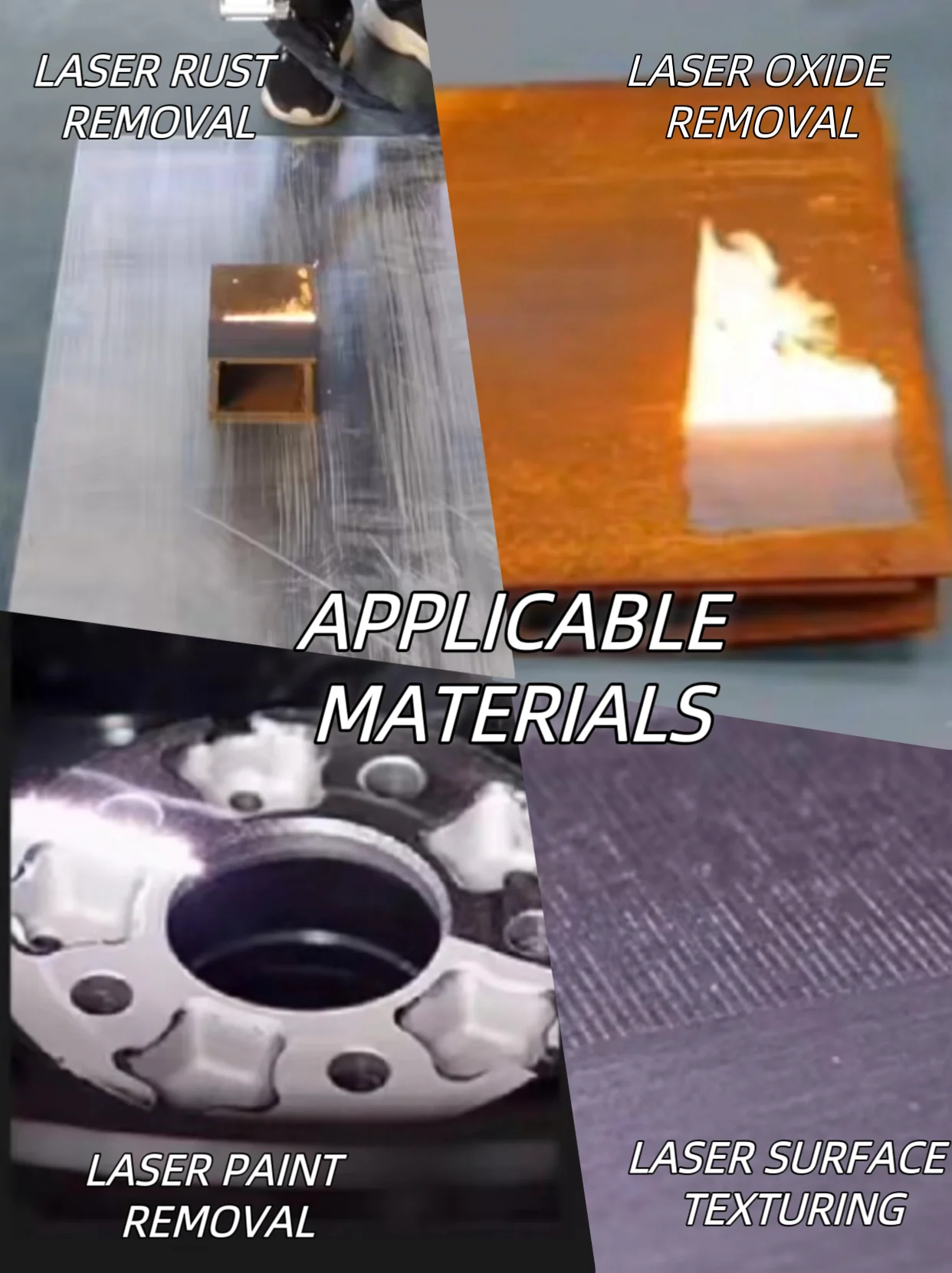

Applications :Mold cleaning, paint stripping,rust and coating removal, pre-treatment of parts before spraying, aerospace parts cleaning, pre-treatment of oxides removal before welding or soldering, oil and product residue removal, cleaning and repair of

cultural relics. Applicable industries:Aeronautical and marine, electromechanical, rubber molds, equipment manufacturing,

automotive parts, food processing.

cultural relics. Applicable industries:Aeronautical and marine, electromechanical, rubber molds, equipment manufacturing,

automotive parts, food processing.

Laser Cleaner Product Description

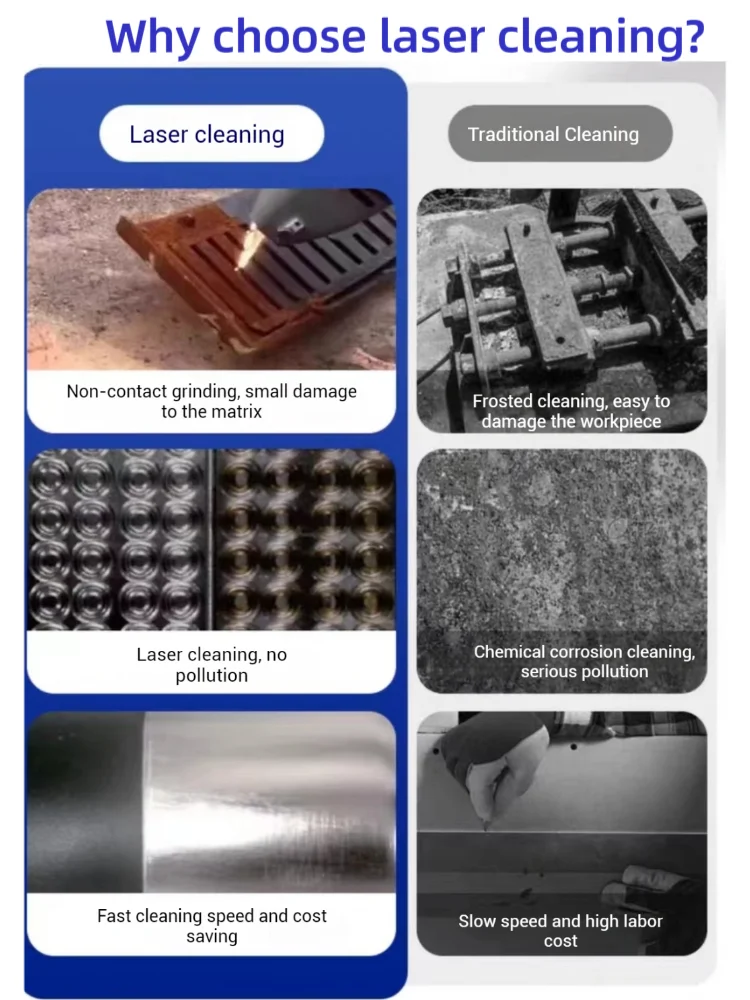

A new generation of high-tech products for efficient industrial cleaning Equipped with a continuous fiber laser, especially suitable for large-scale and high-speed cleaning, brand fiber laser source, strong removal of stubborn oil stains, rust layer, residual paint and other impurities on the metal surface.

Powerful cleaning Stable and reliable. Non-contact cleaning to protect the parent material, no chemical reagents green, without the need for expensive and complex waste disposal. Application efficacy includes: rust removal, paint removal, oil removal, cultural relics restoration, adhesive removal, de-coating, de-plating.

Why Use Laser Cleaner?

Environmental advantages:

Laser cleaning is a "green" cleaning method, do not need to use any chemicals and cleaning fluid, cleaning down the waste is basically a solid powder, small size, easy to store, recyclable, no photochemical reaction, will not produce pollution.

Effectiveness advantages:

Control advantages:

Convenience advantages:

Laser cleaning is a "green" cleaning method, do not need to use any chemicals and cleaning fluid, cleaning down the waste is basically a solid powder, small size, easy to store, recyclable, no photochemical reaction, will not produce pollution.

Effectiveness advantages:

Traditional cleaning methods are often contact cleaning, cleaning the surface of the object has a mechanical force, damage to the surface of the object or cleaning medium attached to the surface of the object being cleaned, can not be removed, resulting in secondary pollution, laser cleaning of non-abrasive and non-contact, non-thermal effect will not damage the substrate, so that these problems are solved.

Control advantages:

The laser can be transmitted by fiber optics, convenient to achieve long-distance operation, can clean the parts that traditional method is not easy to reach or the places where are dangerous and we can not ensure the safety of personnel.

Convenience advantages:

Laser cleaning can remove all types of contaminants from the surface of various materials, achieving a level of cleanliness that cannot be achieved with conventional cleaning. Moreover, it is possible to selectively clean contaminants on the material surface without damaging it.

Cost advantages:

Laser cleaning is high speed, high efficiency, and saving time; at this stage to buy a laser cleaning system, although the initial one-time investment is high, but the cleaning system can be used for a long time and stable, at low operating costs, and more importantly, it can be convenient to automate the operate. It can be foreseen that the cost of laser cleaning system in the future will also be a substantial decline, thus further reduce the cost of using laser cleaning technology.

FAQ:

1. What can be cleaned and what can not be cleaned?

1)Paint on metal: Yes. Thick need to clean a few more times, need high power

2)Oxide on the metal: Yes

3)Rust on carbon steel plate: Yes

4)Rust on steel plate: Yes

5)Paint on glass: Yes

6)Paint on wood (furniture paint removal): Yes

7)Oxide bubbles: need to be knocked off, the laser can not be cleaned off, but can be cleaned of residual rust

8)Latex paint on bricks: thin can, thick need to shovel with

9)Paint on fiberglass: No, high temperature will make the fiberglass melt or deformation

10)Paint on leather: No, high temperature will make the leather melt or deformation

2. Should I choose a continuous laser cleaner or a pulsed laser cleaner?

If you want to clean very thick or often clean, and the value of the items is not very high, it is best to need a continuous type,so that the efficiency is higher!

Pulse cleaner is much more expensive, the cleaning beam is much narrower, that is, the cleaning efficiency will be slow, but it is more than continuous type does not hurt the surface of the parent material, more suitable for cleaning small items of high value.

3、What is the scanning width for cleaning?

300mm, need to configure F800 cleaning lens.

4、What kind of shielding gas should I connect?

Cleaning require cold dry compressed air. The flow rate is usually between 10~30 L/min, which needs to be adjusted according tothe actual situation.

1)Paint on metal: Yes. Thick need to clean a few more times, need high power

2)Oxide on the metal: Yes

3)Rust on carbon steel plate: Yes

4)Rust on steel plate: Yes

5)Paint on glass: Yes

6)Paint on wood (furniture paint removal): Yes

7)Oxide bubbles: need to be knocked off, the laser can not be cleaned off, but can be cleaned of residual rust

8)Latex paint on bricks: thin can, thick need to shovel with

9)Paint on fiberglass: No, high temperature will make the fiberglass melt or deformation

10)Paint on leather: No, high temperature will make the leather melt or deformation

2. Should I choose a continuous laser cleaner or a pulsed laser cleaner?

If you want to clean very thick or often clean, and the value of the items is not very high, it is best to need a continuous type,so that the efficiency is higher!

Pulse cleaner is much more expensive, the cleaning beam is much narrower, that is, the cleaning efficiency will be slow, but it is more than continuous type does not hurt the surface of the parent material, more suitable for cleaning small items of high value.

3、What is the scanning width for cleaning?

300mm, need to configure F800 cleaning lens.

4、What kind of shielding gas should I connect?

Cleaning require cold dry compressed air. The flow rate is usually between 10~30 L/min, which needs to be adjusted according tothe actual situation.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices