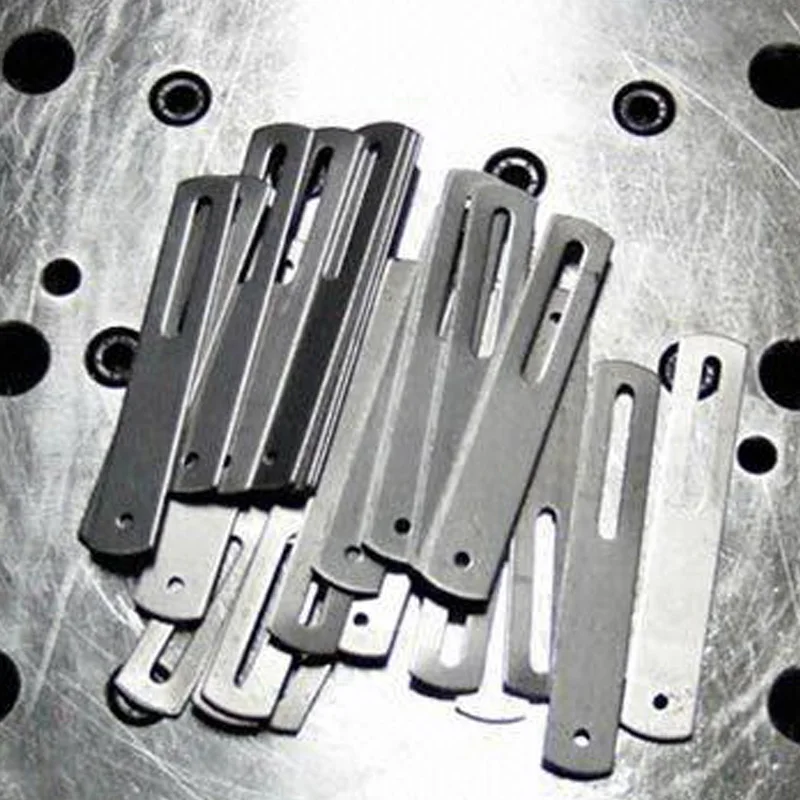

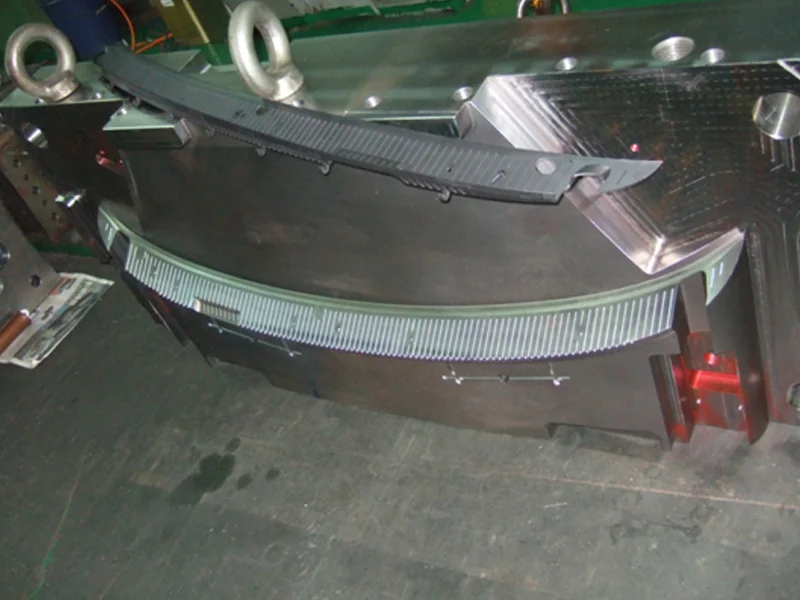

High Precision Stamping Car Components for Automotive Parts

- Category: >>>

- Supplier: INTERTECH MACHINERY INCORPORATIONINTERTECH INCORPORATION

Share on (10000021749091):

Product Overview

Description

Product Description

Specification

item | value |

Place of Origin | Taiwan |

Brand Name | intertech(Taiwan) |

Shaping Mode | Die Casting |

Product Material | metal |

Company Profile

Injection Molding FAQ

Q1: What's the MOQ?

Q2: Types of molding services?

Q3: Secondary operations and decorating?

Q4: Quality certifications?

Q5: Lead-time for molds/tools?

Q7: Designing considerations for injection molding?

Design-Engineering

Mold Application

Molding-Parts Application

Getting Quotation

Q1: What's the MOQ?

A1: Preferably 2,000, 3,000, or 5,000pcs. For low volumes, prices are higher. Discussable per project.

Q2: Types of molding services?

A2: Mainly injection molding. We also offer compression molding, metal punching, engineering design, and prototype testing.

Q3: Secondary operations and decorating?

A3: We offer assembly, ultrasonic welding, glue bonding, silk screening, pad printing, and packaging.

Q4: Quality certifications?

A4: We're SGS certified with a full report available.

Q5: Lead-time for molds/tools?

A5: Varies: 35-60 days for injection molds; 30-45 days for compression molds and punch dies, depending on complexity.

Q6: Mold ownership?

A6: Always the customer's. Full 3D mold designs provided.

Q7: Designing considerations for injection molding?

A7: Material, machine, process, prototyping, color matching, cost, trust agreement, industry reference.

Q8:How does INTERTECH guarantee precise color matching in prototypes and small-batch production?

A8:INTERTECH ensures precise color matching using the PMS (Pantone Matching System) Color Chart for both prototypes and small-batch productions, ensuring consistency and accuracy in color selection.

Design-Engineering

Q1: Do you offer design service?

A1: Yes, we assist in design and problem-solving with our experienced engineers.

Mold Application

Q1: Do you provide mold steel certificates?

A1: Yes, we use high-quality steel imported from Germany and Japan with certifications.

Molding-Parts Application

Q1: Besides molding, do you produce products?

A1: We produce custom molds and products, and offer reverse engineering. No existing molds.

Getting Quotation

Q1: How to get a quote?

A1: Provide 2D, 3D drawings, samples, or photos. Our team evaluates and quotes promptly.

With 30 years of expertise, Intertech stands out as a leading mold making and molding service provider in Taiwan. We specialize in custom plastic molds, industrial components, CNC machining parts, and more. From CAD drawings, we craft precision molds and parts tailored to your needs. Reach out for a swift quotation!

1. QUOTATION INFO Please provide: • CAD Drawings:

2D (.PDF, .DWG) | 3D (.STP, .STEP, .X_T, .IGS, .IGES) • Material: E.g., ABS, PP, PC, Copper, etc. • Surface Finish: E.g., EDM,

texture, etc. • Quantity: E.g., cavity number, parts number, etc. • Notes: Any specific requirements.

2. ORDER PROCESS

* Submit your order to INTERTECH.

* We'll return with a proforma invoice detailing lead time and payment terms.

3. PRODUCTION Your order enters our streamlined production process:

* Primary Service: Custom mold making

* Parts Production: Custom molded parts

4. QUALITY ASSURANCE Throughout production, rigorous QC measures are in place. QC reports are available upon request.

5. SHIPPING Choose from multiple shipping options:

* Express: FedEx, DHL, TNT, UPS, etc.

* Freight: Air & Sea Freight

* Quotation Terms: Ex Works, FOB, CIF, etc.

Contact Intertech Today for Your Quick Quote!

1. QUOTATION INFO Please provide: • CAD Drawings:

2D (.PDF, .DWG) | 3D (.STP, .STEP, .X_T, .IGS, .IGES) • Material: E.g., ABS, PP, PC, Copper, etc. • Surface Finish: E.g., EDM,

texture, etc. • Quantity: E.g., cavity number, parts number, etc. • Notes: Any specific requirements.

2. ORDER PROCESS

* Submit your order to INTERTECH.

* We'll return with a proforma invoice detailing lead time and payment terms.

3. PRODUCTION Your order enters our streamlined production process:

* Primary Service: Custom mold making

* Parts Production: Custom molded parts

4. QUALITY ASSURANCE Throughout production, rigorous QC measures are in place. QC reports are available upon request.

5. SHIPPING Choose from multiple shipping options:

* Express: FedEx, DHL, TNT, UPS, etc.

* Freight: Air & Sea Freight

* Quotation Terms: Ex Works, FOB, CIF, etc.

Contact Intertech Today for Your Quick Quote!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices