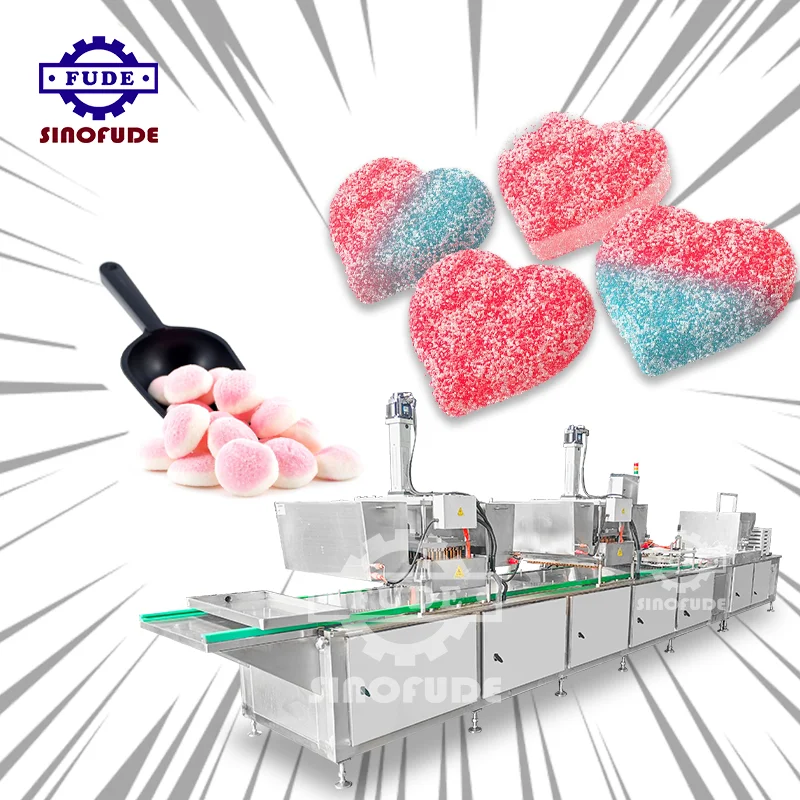

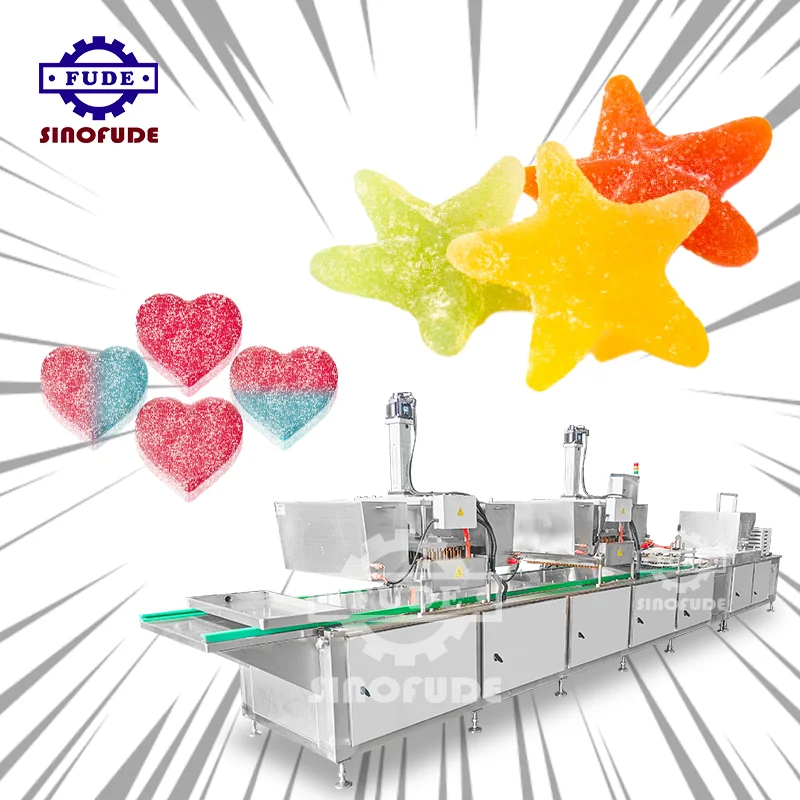

factory direct sale candy making machine semi automatic starch mogul gelatin gummy candy depositing line

- Category: >>>

- Supplier: Shanghai Fude Machinery Manufacturing Co. Ltd.Shanghai Ltd.

Share on (10000023408063):

Product Overview

Description

Model | CLM-S800A | CLM-S1200A |

Capacity(kg/h) | 800kg/h | 1200kg/h |

Steam consumption | 7-8 Bar 850kg/h | 8-10Bar 1000kg/h |

Power | 95kW/380V/50HZ | 120kW/380V/50HZ |

Length | 25m | 35m |

Automatic Weighting and Gel Melting System.

The Automatic Weighting and Gel Melting System in the Starch Mogul production line is the key equipment used to accurately measure and control the weight of the raw materials used in the Starch Mogul production line process. It is mainly composed of weighing device, jacket cooker and electric control cabinet.

The Automatic Weighting and Gel Melting System has the following advantages:

1. High accuracy: The raw material weighing system uses a high-precision scale, which can accurately measure the weight of raw materials in real time. Ensure the quality and taste consistency of hard candy products.

2. Efficiency: The raw material weighing system can quickly measure and process the weight information of raw materials and seamlessly connect with other equipment in the hard candy production line.

3. Flexibility: The raw material weighing system has flexible formula management functions and can store and manage multiple formulas.

4. Data traceability: The raw material weighing system can record and store the raw material weight and other related data of each batch. Ensure traceability of the production process and consistency of quality.

The Automatic Weighting and Gel Melting System has the following advantages:

1. High accuracy: The raw material weighing system uses a high-precision scale, which can accurately measure the weight of raw materials in real time. Ensure the quality and taste consistency of hard candy products.

2. Efficiency: The raw material weighing system can quickly measure and process the weight information of raw materials and seamlessly connect with other equipment in the hard candy production line.

3. Flexibility: The raw material weighing system has flexible formula management functions and can store and manage multiple formulas.

4. Data traceability: The raw material weighing system can record and store the raw material weight and other related data of each batch. Ensure traceability of the production process and consistency of quality.

Automatic Weighing And Mixing System.

The process starts with weighing and mixing of the main ingredients with water,sugar powder,gulcose,dissolved gel.

The ingredients are fed sequentially into a gravimetric weighing and mixing tank and the quantity of each subsequent ingredient is adjusted according to the actual weight of the preceding ones.Program has the function of formula storage.

The Automatic Weighing And Mixing System has the following advantages:

1. High efficiency and energy saving: This machine can heat the syrup to the required temperature in a short time and accelerate the sugar boiling process. At the same time, the vacuum environment can lower the boiling point of the syrup, reduce heat energy loss, and improve energy utilization efficiency.

The ingredients are fed sequentially into a gravimetric weighing and mixing tank and the quantity of each subsequent ingredient is adjusted according to the actual weight of the preceding ones.Program has the function of formula storage.

The Automatic Weighing And Mixing System has the following advantages:

1. High efficiency and energy saving: This machine can heat the syrup to the required temperature in a short time and accelerate the sugar boiling process. At the same time, the vacuum environment can lower the boiling point of the syrup, reduce heat energy loss, and improve energy utilization efficiency.

2. Maintain candy quality: By cooking syrup at a lower temperature, the water in the syrup can evaporate quickly and condense into the basic structure of the candy, avoiding the problem of syrup gelatinization or uneven crystallization caused by excessive heat treatment.

Raising Film Cooking System.

The Raising Film Cooking System is a solution for customers to achieve vacuum thin film cooking of Starch Mogul production line. The Raising Film Cooking System is an efficient candy production equipment that uses Raising Film and vacuum technology to heat and boil sugar.

The Raising Film Cooking System has the following advantages:

The Raising Film Cooking System has the following advantages:

1. Flexibility and controllability: During the sugar boiling process, the operator can set parameters such as heating temperature, vacuum degree, and sugar boiling time through the intelligent control system to meet the production requirements of different candies.

2. System integration:It can complete multiple processes such as heating, stirring, evaporation and condensation of syrup, simplifying the layout and operation process of the production line.

2. System integration:It can complete multiple processes such as heating, stirring, evaporation and condensation of syrup, simplifying the layout and operation process of the production line.

Batch Type CFA System.

CFA batch type adding system are a part of the Gummy Machine and are specially designed and made by SINOFUDE. The syrup and color,flavor and Acid or other liquid additives ingredients will be dosing and inline mixing with the syrup. CFA inline adding system is consists of buffer tank, tanks with load cell and automatic switching valves, PLC control system, warming system. CFA batch type adding system is ideal device Vitamin etc adding and mixing with the gummy syrup.

Batch Type CFA System offer the following two advantages:

The CFA batch type adding system was designed according to Food grade machine standards, higher level sanitary structure design and fabrication, all stainless steel materials are SUS304 and SUS316L in the line and it can be equipped with UL certified or CE certified components for CE or UL certificated.

Batch Type CFA System offer the following two advantages:

The CFA batch type adding system was designed according to Food grade machine standards, higher level sanitary structure design and fabrication, all stainless steel materials are SUS304 and SUS316L in the line and it can be equipped with UL certified or CE certified components for CE or UL certificated.

Forming system.

The all-in-one molding and packaging machine is a device that integrates molding and packaging functions. It can shape raw materials and directly package the finished products to achieve automated production.

Forming systems offer the following two advantages:

1. Save labor costs: Compared with the traditional method of forming and packaging separately, using an all-in-one forming and packaging machine can significantly reduce labor costs.

2. Improve production efficiency: It can complete the molding and packaging of a large number of products in a short time, improving the output speed of the production line.

Forming systems offer the following two advantages:

1. Save labor costs: Compared with the traditional method of forming and packaging separately, using an all-in-one forming and packaging machine can significantly reduce labor costs.

2. Improve production efficiency: It can complete the molding and packaging of a large number of products in a short time, improving the output speed of the production line.

3. Reduce the error rate: The machine can maintain consistent operation during the forming and packaging process, reducing the possibility of errors and improving product consistency and quality stability.

4. Save space: Compared with using forming machines and packaging machines separately, the integrated forming and packaging machine can save space in the production plant and improve the layout flexibility of the production line.

Sugar/Oil coating machine.

Oil coater:The oil-coating machine is newly designed and manufactured by SINOFUDE, it's a necessary device for coating the oil on the starchless formed or mogul line formed jelly/gummy candy or other products that need to be coated by oil. It is made of Stainless Steel SUS304/SUS316 (optional) rotating drum.It is a double-layer structure with a smooth surface on the inner cylinder. During normal production, the inner cylinder will rotate, and the oil spraying device will evenly spray oil inside the cylinder until all the oil is wrapped on the candy.

The sugar-coating machine (sugar sanding machine) is newly designed and manufactured by SINOFUDE, its a necessary device for coating the sugar on the starchless formed or mogul line formed jelly/gummy candy or marshmallow or other products that need to be coated by sugar or other grains. It is made of Stainless Steel SUS304/SUS316 (optional) rotating drum. It is double layer structure, there is holes in the inner drum, and when normal production, the rest of sugar will be recycling used till all sugar are coated on candies. The machine is also optional equipped with sugar feeding devices by time control for continuous production.

The steaming conveyor can be added also for better coating as optional items.

The steaming conveyor can be added also for better coating as optional items.

Our Services

1.Are you factory?

Yes. we are factory. We are professional manufacturer of vitamin gummies machine and functional candies machine.

2.Do you have OEM service?

You can request machine brand/function/size/output/shape/packaging, etc.

3.Do you provide any recipes for the product?

Yes, we will provide a basic recipe. And clients canadd different color and flavor on that base.

4.Can you guarantee the quality of the machine?

Of course, all parts of our machine in contact with food are made of food-grade SUS316 material, and we will give you a two-year machine warranty and permanent after-sales service.

5.After purchasing your machine, what should I do if it cannot be installed and used?

Our machine is designed to be "plug and play". Each part is controlled by an independent electric cabinet. Customers only need to turn on the power to run the machine, and our engineers can go to the local for machine training and installation.

2.Do you have OEM service?

You can request machine brand/function/size/output/shape/packaging, etc.

3.Do you provide any recipes for the product?

Yes, we will provide a basic recipe. And clients canadd different color and flavor on that base.

4.Can you guarantee the quality of the machine?

Of course, all parts of our machine in contact with food are made of food-grade SUS316 material, and we will give you a two-year machine warranty and permanent after-sales service.

5.After purchasing your machine, what should I do if it cannot be installed and used?

Our machine is designed to be "plug and play". Each part is controlled by an independent electric cabinet. Customers only need to turn on the power to run the machine, and our engineers can go to the local for machine training and installation.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices