China Woodworking Factory Customized production line steel doors High Efficiency mdf door production line

- Category: >>>

- Supplier: Foshan Leader Machinery Co. Ltd.

Share on (11000005710323):

Product Overview

Description

SOLUTION

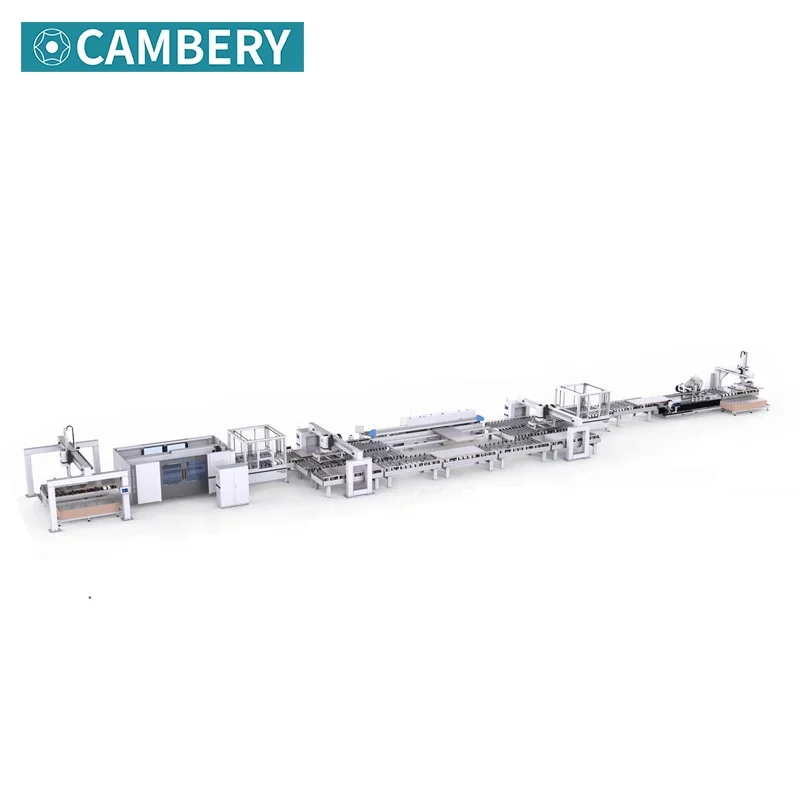

Automatic Wooden Door Production Line

The Automatic wooden door production line comprises a four-side saw, edge banding machine, door hinge/door lock hole, and up/down hardware pre-assembly machine. This wooden door production line only needs 3-4 people and can produce 350-400 doors a day/8 hour. Leadertech has a professional team of engineers who will design a tailored solution for you, providing the one-stop service from factory layout to machine operation.

Product Characteristics:

● 3 Layer construction

● Surface: WPC/MDF/ PVC/veneer/HPL panel

● Core: Solid wood + Foam, Hollow core, solid core

● Glue on edge-banding: EVA

● Edge Tape: PVC/ Veneer

● This production line can reach up to 350-400 pieces of standard-size door within 8 hours

● 3-5 workers are needed, saving labor costs.

● Surface: WPC/MDF/ PVC/veneer/HPL panel

● Core: Solid wood + Foam, Hollow core, solid core

● Glue on edge-banding: EVA

● Edge Tape: PVC/ Veneer

● This production line can reach up to 350-400 pieces of standard-size door within 8 hours

● 3-5 workers are needed, saving labor costs.

Layout:

PARAMETER INFORMATION

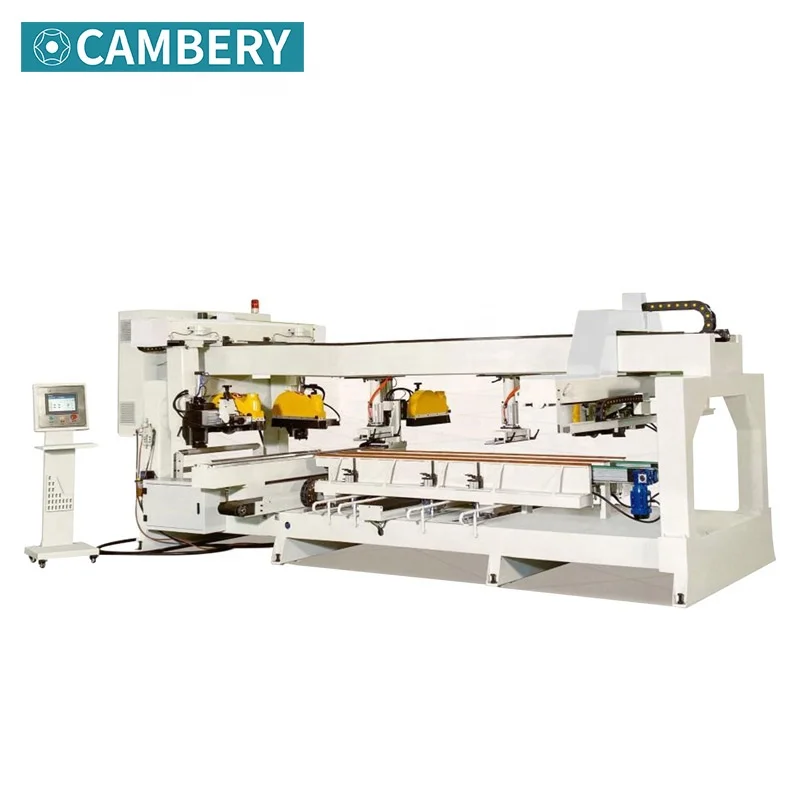

01 Four Sides Sawing

Saw cutting table outer contour

Overall Size

Overall Size

● Space:

Approx. 5410 mm*3600 mm*2300 mm

● Total power: 33 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

Approx. 5410 mm*3600 mm*2300 mm

● Total power: 33 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

● Door size:

Length: 1800-3000 mm

Width: 550-1100 mm

Thickness: 30-65 mm

● Saw Power:

Main saw 7.5 KW 4 SET

● Scoring Saw 0.75 KW 4 SET

Length: 1800-3000 mm

Width: 550-1100 mm

Thickness: 30-65 mm

● Saw Power:

Main saw 7.5 KW 4 SET

● Scoring Saw 0.75 KW 4 SET

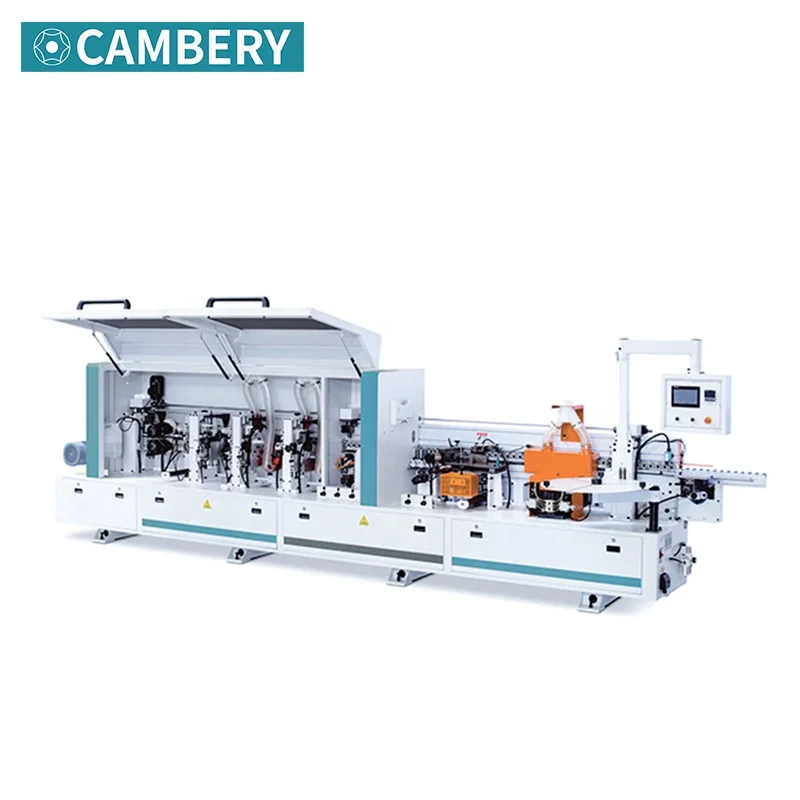

02 Edge banding of Flush Doors

● Space: Approx. 5800 mm*800 mm*1600 mm

● Total power: 16 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

● Feeding Speed: Up to 23 m/min

● Panel Size:

● Total power: 16 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

● Feeding Speed: Up to 23 m/min

● Panel Size:

Min. Working Size: From 120 mm*95 mm

Thickness: 9-60 mm

Edge Tape:

Thick: 0.4-3 mm

Width: 12-65 mm

Thickness: 9-60 mm

Edge Tape:

Thick: 0.4-3 mm

Width: 12-65 mm

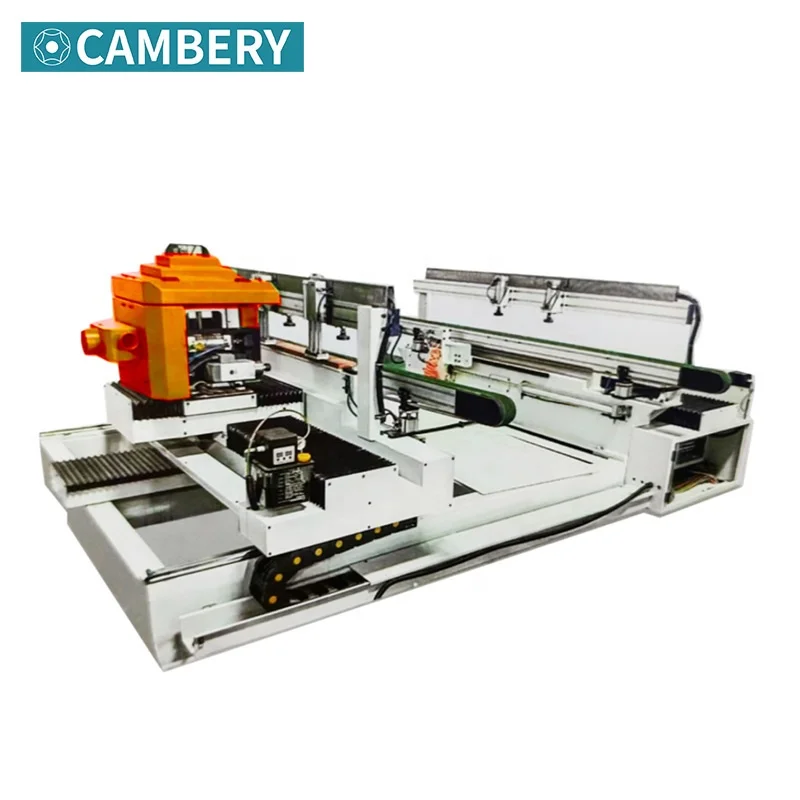

03 Making keyholes and door hinge hole

● Space: 4300 mm*2000 mm*1850 mm

● Total power: 28 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

● Top Spindles:

3.7 kw @9000 r/min, for scoring or boring.

3.7 kw @9000 r/min, for slot milling.

● Side Spindles:

3.7 kw @9000 r/min, for scoring or boring.

0.75 kw @9000 r/min, for slot milling.

● Working Size: Up to 3000*1100*80 mm

● Milling Depth: Up to 115 mm

● Total power: 28 kw

● Power Loaded: 380 V 50 Hz 3 Phase

● Pneumatic loaded:0.6~0.8 MPa

● Top Spindles:

3.7 kw @9000 r/min, for scoring or boring.

3.7 kw @9000 r/min, for slot milling.

● Side Spindles:

3.7 kw @9000 r/min, for scoring or boring.

0.75 kw @9000 r/min, for slot milling.

● Working Size: Up to 3000*1100*80 mm

● Milling Depth: Up to 115 mm

04 Making door Top/Bottom hole

● Space: 4500 mm*2000 mm*1850 mm

●Total power: 26 kw

●Power Loaded: 380 V 50 Hz 3 Phase

●Pneumatic loaded:0.6~0.8 MPa

●Spindles:

3.7 kw @9000 r/min 2 set

0.75 kw @9000 r/min 2 set

●Working Size: Up to 3000*1100*80 mm

●Milling Depth: Up to 115 mm

●Total power: 26 kw

●Power Loaded: 380 V 50 Hz 3 Phase

●Pneumatic loaded:0.6~0.8 MPa

●Spindles:

3.7 kw @9000 r/min 2 set

0.75 kw @9000 r/min 2 set

●Working Size: Up to 3000*1100*80 mm

●Milling Depth: Up to 115 mm

Wooden Door Production Processes

HOT SALE

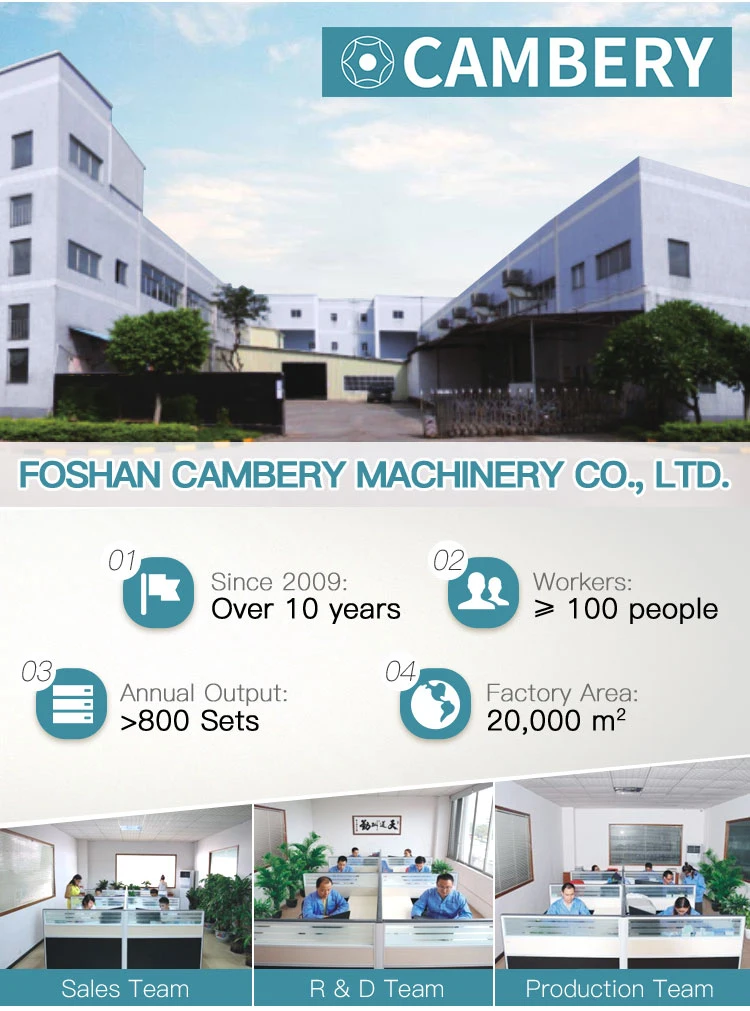

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices