Small Ampoule Filling Sealing Printing Carton Box Packing Assembly Machine Production Line

- Category: >>>

- Supplier: Shanghai Iven Medical Technology Co. Ltd.

Share on (11000014287815):

Product Overview

Description

Brief Introduction

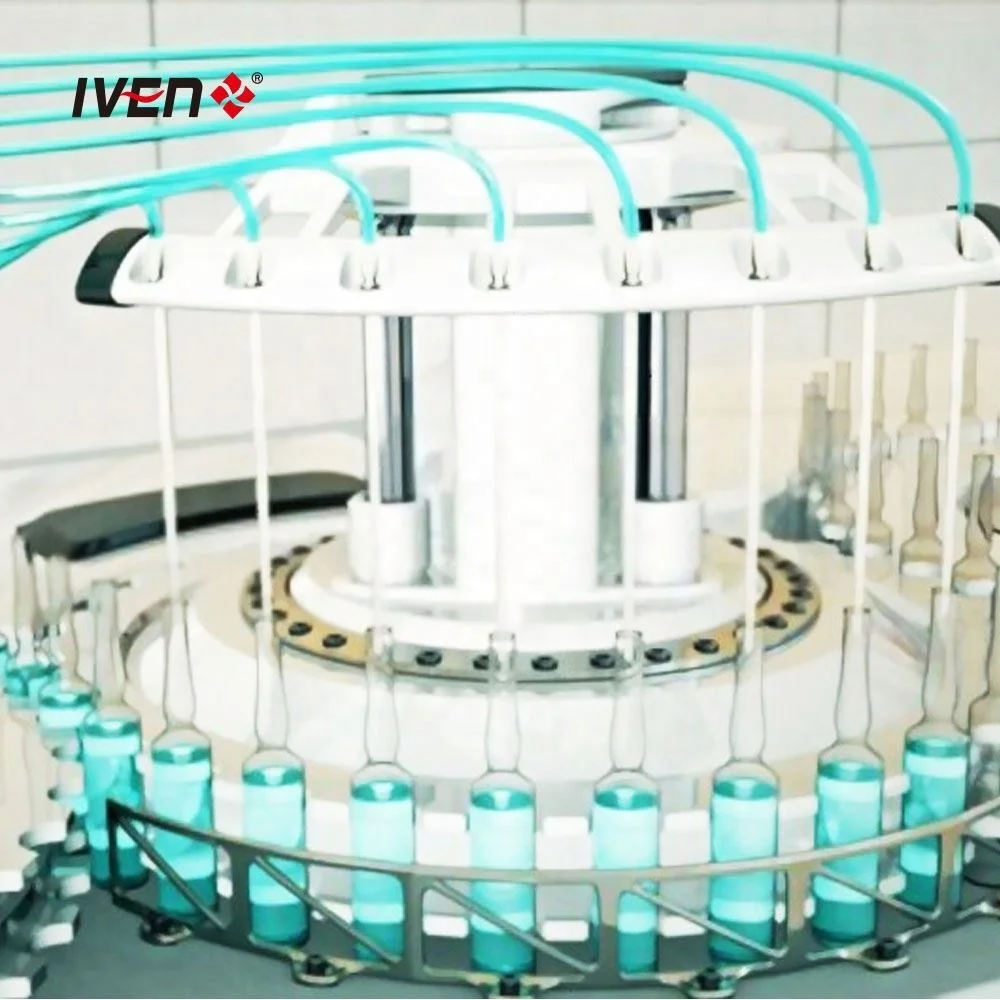

BXAZ ampoule cleaning, drying, filling and sealing compact production line is a new type of ampoule production line which adopted the advanced international technology, combined several FE Pharmatech’s patents and according to the domestic ampoule production situation.

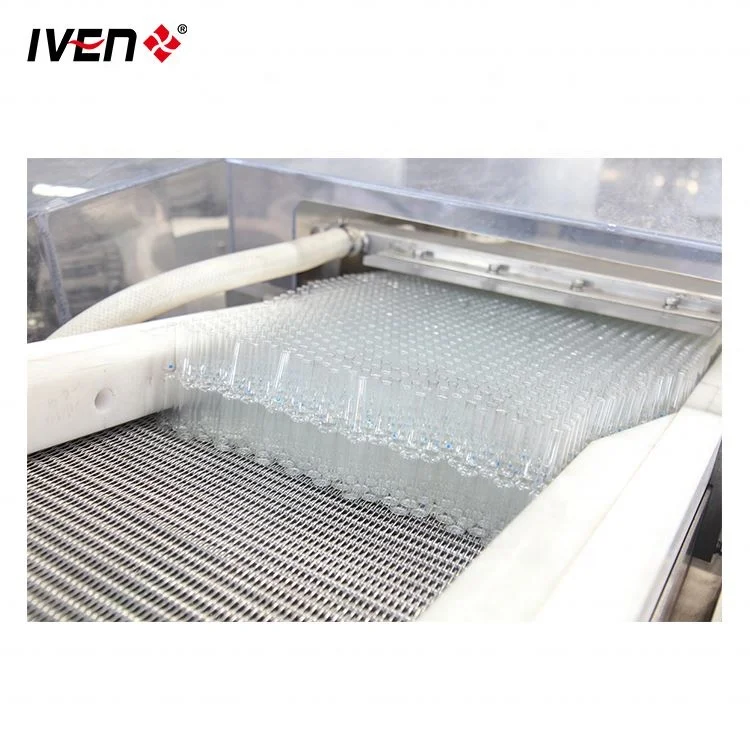

This line is composed by CLQ vertical ultrasonic cleaning machine, RSM sterilizing drying machine and AGF filling and sealing machine. It is divided into cleaning zone, sterilizing zone, filling and sealing zone.

This compact line can work together as well as independently.

Main Features

1The compact line realizes single linkage, continuous operation from washing, sterilizing,filling and sealing. The whole production process realizes cleaning operation; protects products from contamination, meets the GMP production standard.

2 This line adopts water and compressed air cross pressure jet wash and ultrasonic wash at inverted state. The cleaning effect is very good.

3 The ultra filtration technology is applied at the washing machine’s filter. The clean and sterile washing water and compressed air is obtained through terminal filter, which can improve the clarity of the washed bottle.

4 Bottle infeed auger and star wheel meet, the auger space is small. Ampoules can walk straight. Ampoules can transfer more stable and can hardly broken.

5 Double tank and double circulation. The circulation water tank and rough wash water tank are totally separate. The cleaning water is used step by step. The cleaning effect is much better.

6 The stainless manipulators are one side fix. The location is more accuracy. The manipulators are wearproof. When changing of pitch the manipulators no need stretch out and turn. The turning bearing wont contaminating the cleaning water.

7 The ampoules are sterilized by the hot air laminar flow sterilization principle. The heat distribution is more even. The ampoules are under the HDC high temperature sterilization condition, which meets the standard of GMP.

8 This equipment adopts negative pressure sealing principle to seal the high efficiency filter which are used for purify the tunnel. The filter is easy to install which can ensure the one hundred purification condition.

9 The equipment adopts hinge type seat heat and horizontal hot air fan structure. The maintenance of the equipment is more convenient and laborsaving.

10 This equipment adopts chain conveying belt with flank. The conveying belt won’t be off track, anticreeper, no bottle falling.

11 The equipment adopts advance technology such as multi-needle filling, front and rear nitrogen charging and wire drawing sealing, which can meet the standard of different type of products.

12 The fill-seal machine adopts balcony structure. The starwheel infeed and convey bottles continuously, the running of the equipment is stable and less bottle breakage.

13 This equipment is universal. It can’t be used to 1-20ml ampoules. Changing parts are convenient. In the meantime, the equipment can be used as vial washing, filling and capping compact line by changing some mould and outfeed wheel.

Technical Parameters

| Applicable specifications | 1-20ml B type ampoules which meets the standard of GB2637. |

| Maximum capacity | 7,000-10,000pcs/h |

| WFI consumption | 0.2-0.3Mpa 1.0 m3/h |

| Compressed air consumption | 0.4Mpa 50 m3/h |

| Electric capacity | CLQ114Vertical ultrasonic washing machine:15.7KW |

| RSM620/60 Sterilizing and drying machine 46KW, heating power: 38KW | |

| AGF12 Ampoule filling and sealing machine 2.6KW | |

| Dimensions | CLQ114Vertical ultrasonic washing machine:2500×2500×1300mm |

| RSM620/60 Sterilizing and drying machine:4280×1650×2400mm | |

| AGF12 Ampoule filling and sealing machine:3700×1700×1380 mm | |

| Weight | CLQ114Vertical ultrasonic washing machine:2600 Kg |

| RSM620/60 Sterilizing and drying machine:4200 Kg | |

| AGF12 Ampoule filling and sealing machine:2600 Kg |

IVEN Can Do !

IVEN provides integrated engineering solution for worldwide manufacturing factory include the clean room, auto-control and monitoring system, water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system and central laboratory and etc. According to the manufacturing industry's regulatory requirements of different countries and customer's individual demand, IVEN carefully customizes engineering solutions of turnkey projects and helps customers to win the target markets, IVEN creates value to customers.

Turnkey Project for IV Solution Plant from A to Z

• Project Design

• Water Treatment

• Solution Preparation

• IV Solution Production Line

• Sterilization

• Inspections Packing

• Clean Room & HVAC

• Stability Chamber

• Laboratory Instruments

• Utilities

• Documentation & Qualification

• Installation, Commissioning, Training

• Service

Oversea Projects

Project Display

Hot Products

Our Exhibition

Packaging & Shipping

FAQ

We Recommend

New Arrivals

New products from manufacturers at wholesale prices