Plastic Gravel Grid Driveway Stabilizer for Slope Soil

- Category: >>>

- Supplier: Qingdao Taimei Products Co. Ltd.

Share on (11000015808115):

Product Overview

Description

Products Description

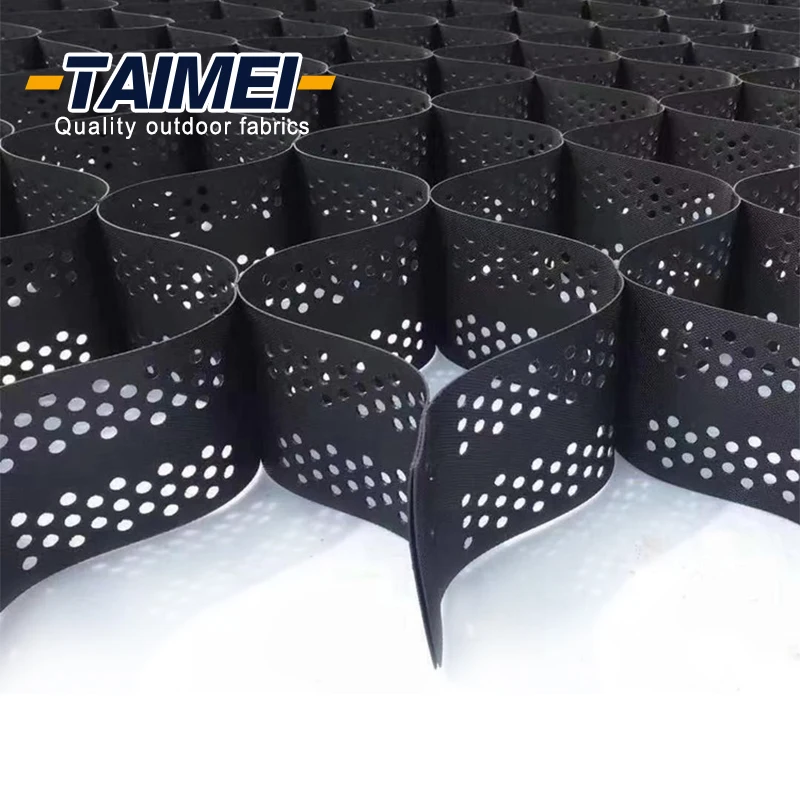

Reinforced HDPE Geocell Cellular Confinement System for Slope Protection

GEOCELL is produced from High Density Polyethylene (HDPE) and has a three-dimensional cellular confinement system that confines and strengthens infill material including native fill, topsoil, granular or concrete, within the cells of its honeycomb-like structure.

Within the interconnected cells, TERATUF GEOCELL serves many benefits to the material it confines, such as boosting weight-bearing capabilities, preventing lateral movement, and providing durable stabilization. There are four main applications that geocell provides solutions: soil stabilization, erosion control, channel protection, and retaining walls. It is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Geocells are use in civil engineering for protection and stabilization applications. They are often used to help improve the performance of standard construction materials and erosion-control treatments.

Within the interconnected cells, TERATUF GEOCELL serves many benefits to the material it confines, such as boosting weight-bearing capabilities, preventing lateral movement, and providing durable stabilization. There are four main applications that geocell provides solutions: soil stabilization, erosion control, channel protection, and retaining walls. It is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Geocells are use in civil engineering for protection and stabilization applications. They are often used to help improve the performance of standard construction materials and erosion-control treatments.

Main Application

Base Stabilization

Geocell is a confinement system that performs better than conventional crushed stone sections, and it provides an expedient construction technique for access roads over soft ground without being adversely affected by wet weather conditions. Geocell can also be used to strengthen paved areas.

Slope Reinforcement

On slope applications, Geocell can be filled with angular rock, concrete or with vegetated soil. The Geocell confine the infill material, creating a stable layer protecting the slope from erosion. Geocell is a flexible system that will contour to the subgrade of a slope, reducing preparation time. When filled with vegetated soil or rock, the system is permeable - reducing water runoff.

Channel Protection

Geocell can be installed on slopes as steep as 60 degrees and on channels with flow velocities greater than 25 ft/s (7.6 m/s), depending on infill material. Angular rock is used for velocities up to 10 ft/s (3 m/s), vegetated soil up to 20 ft/s (6 m/s) and concrete for velocities greater than 20 ft/s (6m/s).

Retaining Walls

Geocell can be used for both cut and fill applications on retaining walls. The flexible panels are custom made to the front to back dimensions required by the project engineer. Geocell can be easily installed around curves, pipes or other structures. Geocell panels can be stacked to create a 90 degree wall, or they can be stair stepped at every layer to create exposed cell for vegetation.

The Advantage of Geocell

- Provides cost effective, long-term slope and channel protection and stabilization.

- Ease in transportation and on-site handling due to collapsible cells.

- Rapid and simple installation conforms to most terrain profiles.

- Ultrasonic welding of cell joints ensures maximum strength.

- Easily dismantled and subsequently re-used.

- Withstands high weight bearing loads.

- Resistant to biological attack and a wide range of soil borne chemicals.

Details Images

FEATURES:

1. High Grade Raw Material to Ensure the Product Performance

Use virgin HDPE material to assure consistent, reproducible, and long-lasting performance.

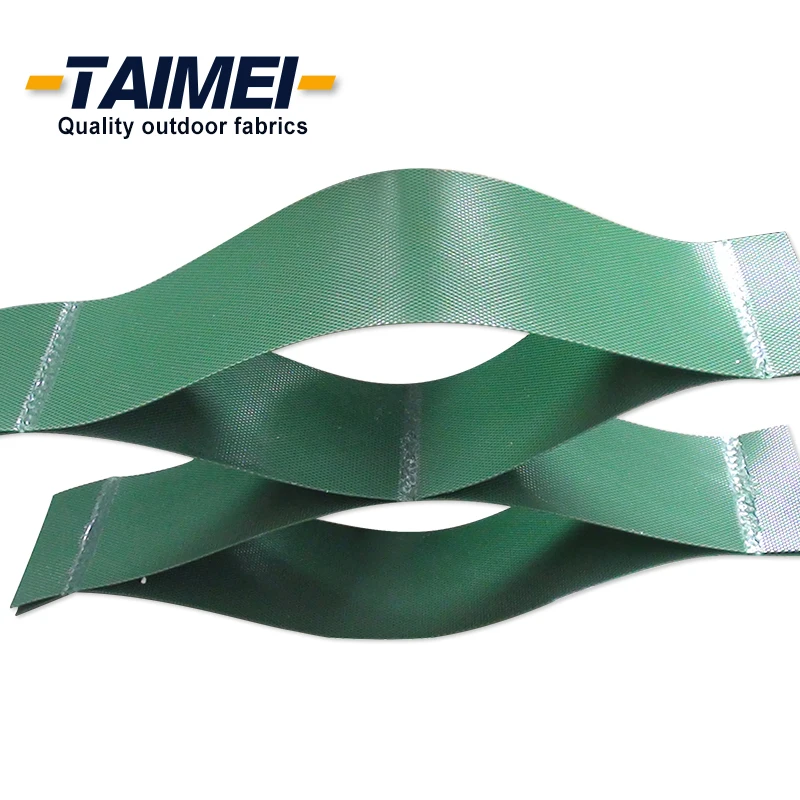

2. Ultrasonic Wedling to Ensure the Strength of the Seam.

Strong weld continually tested to project assurance.

3. Honeycomb Structure to Bearing Heavy Load

Prevent horizontal movement, and increase both shear strength and bearing capacity.

4. Proformed Hole to Allow Water to Get Through

Prevents erosion, and allow water flow.

Use virgin HDPE material to assure consistent, reproducible, and long-lasting performance.

2. Ultrasonic Wedling to Ensure the Strength of the Seam.

Strong weld continually tested to project assurance.

3. Honeycomb Structure to Bearing Heavy Load

Prevent horizontal movement, and increase both shear strength and bearing capacity.

4. Proformed Hole to Allow Water to Get Through

Prevents erosion, and allow water flow.

Product Specifications

MATERIAL PROPERTIES | ||||||||

ITEM | UNIT | RESULT | TEST STANDARD | |||||

Polymer density | g/cm³ | 0.935-0.965 | ASTM D 1505 | |||||

Environmental stress crack resistance | hrs | >5000 | ASTM D 1693 | |||||

Carbon black content | % | min.2.0 | ASTM D 1605 | |||||

Nominal sheet thickness (post texturing) | mm | min.1.52 | ASTM D 5199 | |||||

Material | Compound of various Polyethylenes and additives | _ | ||||||

Texture | Polyethylene strip consists of a multiple rhomboidal indentations, over the entire strip area on both sides of the strip. The indentations have a surface density of 22 to 32 per cm2 | _ | ||||||

Perforations | Polyethylene strip is perforated with horizontal rows of maximum 10 mm diameter holes. Cell perforations area is less than 12% of cell surface area | _ | ||||||

Cell/ Section properties | ||||||||||||||||||

Property | UNIT | TM330 | TM356 | TM400 | TM500 | TM600 | TM712 | TM800 | TM1000 | |||||||||

Weld spacing (± 3%) | mm | 330 | 356 | 400 | 500 | 600 | 712 | 800 | 1000 | |||||||||

Cell Depth (± 3%) | mm | 50,75,100,150,200,250 | ||||||||||||||||

Expanded cell dimensions (± 3%) width | mm | 244 | 263 | 296 | 370 | 444 | 527 | 592 | 740 | |||||||||

Expanded cell dimensions (3%) length | mm | 205 | 221 | 249 | 311 | 373 | 442 | 497 | 621 | |||||||||

Expanded cell area(± 3%) | cm2 | 250 | 291 | 368 | 574 | 827 | 1165 | 1471 | 2298 | |||||||||

Nominal expanded section width | m | 5.61 | 5.52 | 5.62 | 5.55 | 5.33 | 5.27 | 5.33 | 5.18 | |||||||||

Nominal expanded section length | m | 6.56 | 7.08 | 7.95 | 9.94 | 11.93 | 14.16 | 15.91 | 19.88 | |||||||||

Nominal expanded section area | ㎡ | 36.81 | 39.07 | 44.69 | 55.17 | 63.58 | 74.60 | 84.78 | 102.99 | |||||||||

Seam properties | Cell Depth | |||||||||||||||||

mm | 50 | 75 | 150 | 200 | ||||||||||||||

Seam peel strength (US ACE Technical report, GL-86-19) | N | 710 | 1065 | 2130 | 2840 | |||||||||||||

Applications

What Geocell Use For?

To bear the load of dyke, retaining wall.

To improve the watercourse of shallow river.

To support the pipeline and sewer.

To be used as independent wall, wharf and breakwater, etc..

To be used for the regulation of the desert, beaches, river bed and river bank.

APPLICATION IN

4 SECTIONS

- Soil Stabilization

- Erosion Control

- Channel Protection

- Retaining Walls

Why Choose Us

Professional OEM of Industrial Textile for 15 years.

TAIMEI Group is a ISO9001 certificated supplier of coated and un-coated woven textile, extruded films and sun shade covers. We headquartered in Qingdao, is responsible for marketing and R&D, while manufacturers in Weihai, Qingdao, Binzhou and Tai'An cities, handling production. With 15+ years of group experience in manufacturing, our production teams have 20+ years of experience in the production of a different kind of fabric, 380+ customers in 60+ countries worldwide, and for a variety of markets, applications and end-users.

In order to provide more professional fabric and finished products to our clients, we split our business to 4 divisions: Woven Division, Geosynthesis Division, Shade Fabric Division, and Tarpaulin Division. To provide many different fabric for different application.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices