ZDW43J 8*1600 Uncoiler Machine Manual

- Category: >>>

- Supplier: Jiangsu Tewei Machine Tool Manufacturing Co. Ltd.

Share on (1154978544):

Product Overview

Description

Product Description

Machine Overview

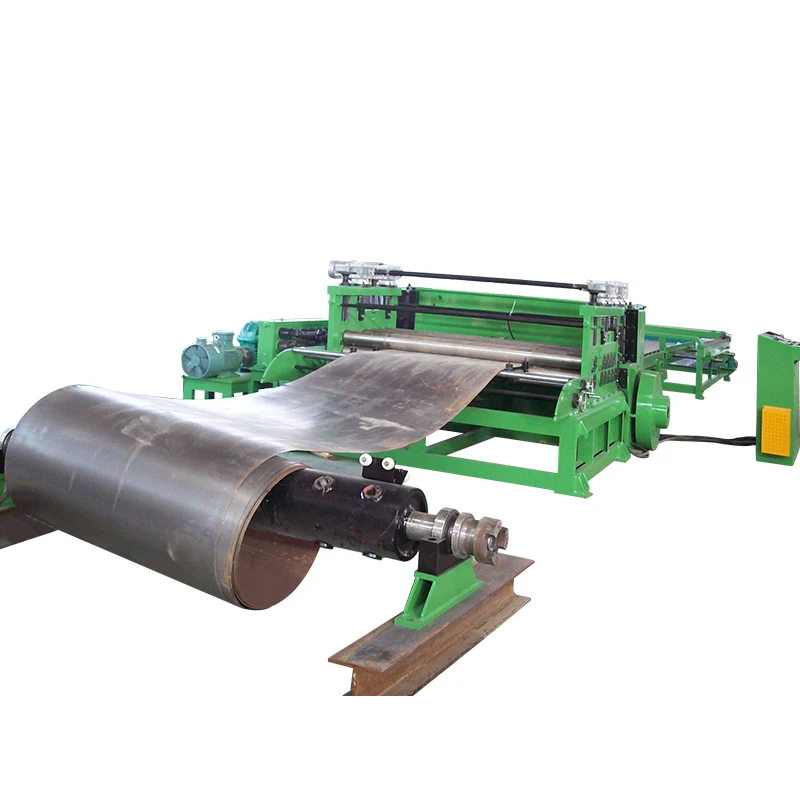

This Machine Used To Spread The Steel Coil, Leveling And Cut To The Request Size. After Manual Feed Into The Leveling Machine, As The Cutting Size, The Unit Will Finish The Leveling And Cutting Action.

Equipment Combination.

1).Decoiler---2).Side Guiding Unit---3).Leveling Machine---4).Cutting Machine---5).Stack Table---6).Electric System

This Machine Used To Spread The Steel Coil, Leveling And Cut To The Request Size. After Manual Feed Into The Leveling Machine, As The Cutting Size, The Unit Will Finish The Leveling And Cutting Action.

Equipment Combination.

1).Decoiler---2).Side Guiding Unit---3).Leveling Machine---4).Cutting Machine---5).Stack Table---6).Electric System

Equipment structure and function

1.Uncoiler:Used to support the coil , bearing 25 tons. By the support shaft, frame and other components . Sent to board the first artificial leveling machine , leveling machine driven by the coil to start .

2. Side guiding:Sheet to prevent run-time deviation , both sides of the sheet width direction with vertical guide rollers , guide roller frame fixed to the respective sliding seat , through the hand wheel by the screw-nut Fushi slide in the lead column along the width direction , to accommodate different width .

3.11 Rollers leveler:Pinch steel and steel plate for correction. From the base , frame , sliding seat rolls , leveler rolls 11 (

under 6 on 5 ) , motor and other components to enhance the pressure adjusting mechanism . By the motor drive gear reducer , so that the next row of rollers are turning .

Adapt to the 1.8-8mm thickness , 1800mm width . Upper straightening rolls ( 5 ) electric lift , pressure .

4.Cutting:Down to size after shear . Mechanical shears .

5.Materials sets:carry on the plates after shearing .

6.Electric system:System includes console , cabinet .

2. Side guiding:Sheet to prevent run-time deviation , both sides of the sheet width direction with vertical guide rollers , guide roller frame fixed to the respective sliding seat , through the hand wheel by the screw-nut Fushi slide in the lead column along the width direction , to accommodate different width .

3.11 Rollers leveler:Pinch steel and steel plate for correction. From the base , frame , sliding seat rolls , leveler rolls 11 (

under 6 on 5 ) , motor and other components to enhance the pressure adjusting mechanism . By the motor drive gear reducer , so that the next row of rollers are turning .

Adapt to the 1.8-8mm thickness , 1800mm width . Upper straightening rolls ( 5 ) electric lift , pressure .

4.Cutting:Down to size after shear . Mechanical shears .

5.Materials sets:carry on the plates after shearing .

6.Electric system:System includes console , cabinet .

1 | coil materials | hot rolled plate Q235-A(account as the strength of materials) |

2 | coil thickness | 2-8mm |

3 | coil width | 800-1600mm |

4 | coil weight | ≤25T |

1 | leveling speed | ~8m/min |

2 | leveling accuracy | 2mm/m(related with original shape) |

3 | scale length tolerance | ±5mm |

4 | main motor power | 30kW |

5 | unit area | (L×W) about 24m×5.5m |

6 | unit working direction | (face to console)from right to left |

Specification

SN | NAME | NOTE | ||

1 | Coil Thickness | 2~8mm | ||

2 | Max Processed Width | 1600mm | ||

3 | Materials | Q235-A σb≤450MPa | ||

4 | Coil Weight | ≤30000kg | ||

5 | Coil Diameters ø800~ø1800 | mm | ||

6 | Plate Open Speed | 125mm/s | ||

7 | Motor | Model | Y200L2-6 | |

Power | 22kW | |||

Rev. | 960r/min | |||

8 | Leveling Accuracy | ≥3mm/m² | ||

9 | Machine Weight | ≥3mm/m² | ||

Packing & Delivery

Recommend Products

Company Profile

Our company is located in Jiangdu of Yangzhou City, on the side of Jianghang Channel, the cross point of Jinghu and Ningtong Expressway. We are engaged in forging machinery manufacturing industry. We specialize in producing plate benders, plate bevel shearing lines, mechanical scribing machines, hydraulic scribing machines, pipe straighteners, pipe benders, semi-automatic submerged arc welding lines, hydraulic plate cutting machines, mechanical plate cutting machines, three-roll bending machines, and large milling machines, as well as common type plate processing in the fields of light pole, electrical pole, machinery, electron, automobile, shipbuilding, electrical home appliance, cooking equipment, and building decoration.

Our company has a strong technical force and advanced processing equipment, and attained ISO9001 international quality system certification in 2003. All our products are manufactured according to the national advanced standards. Our technicians develop many new products meeting the needs of markets, and fill in our national gaps, especially in the fields of light poles and electrical poles manufacturing equipment.

Our aim is "quality competition, price competition, and service competition". Sincerely welcome you to negotiate and cooperate with us.

Our company has a strong technical force and advanced processing equipment, and attained ISO9001 international quality system certification in 2003. All our products are manufactured according to the national advanced standards. Our technicians develop many new products meeting the needs of markets, and fill in our national gaps, especially in the fields of light poles and electrical poles manufacturing equipment.

Our aim is "quality competition, price competition, and service competition". Sincerely welcome you to negotiate and cooperate with us.

FAQ

1. who are we?

We are based in Jiangsu, China, start from 2002,sell to Domestic Market(60.00%),Southeast Asia(15.00%),South Asia(10.00%),South America(5.00%),Eastern Asia(5.00%),Central America(5.00%). There are total about 1-4 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Press Brake,Welding Machine,Shearing Machine

4. why should you buy from us not from other suppliers?

We are the first manufacturer of whole set light pole production line.

Specialized in light pole production line.

Can provide the whole machines in the production line, and we have cooperator who specialized in galvanizing plant.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

We are based in Jiangsu, China, start from 2002,sell to Domestic Market(60.00%),Southeast Asia(15.00%),South Asia(10.00%),South America(5.00%),Eastern Asia(5.00%),Central America(5.00%). There are total about 1-4 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Press Brake,Welding Machine,Shearing Machine

4. why should you buy from us not from other suppliers?

We are the first manufacturer of whole set light pole production line.

Specialized in light pole production line.

Can provide the whole machines in the production line, and we have cooperator who specialized in galvanizing plant.

5. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

We Recommend

New Arrivals

New products from manufacturers at wholesale prices