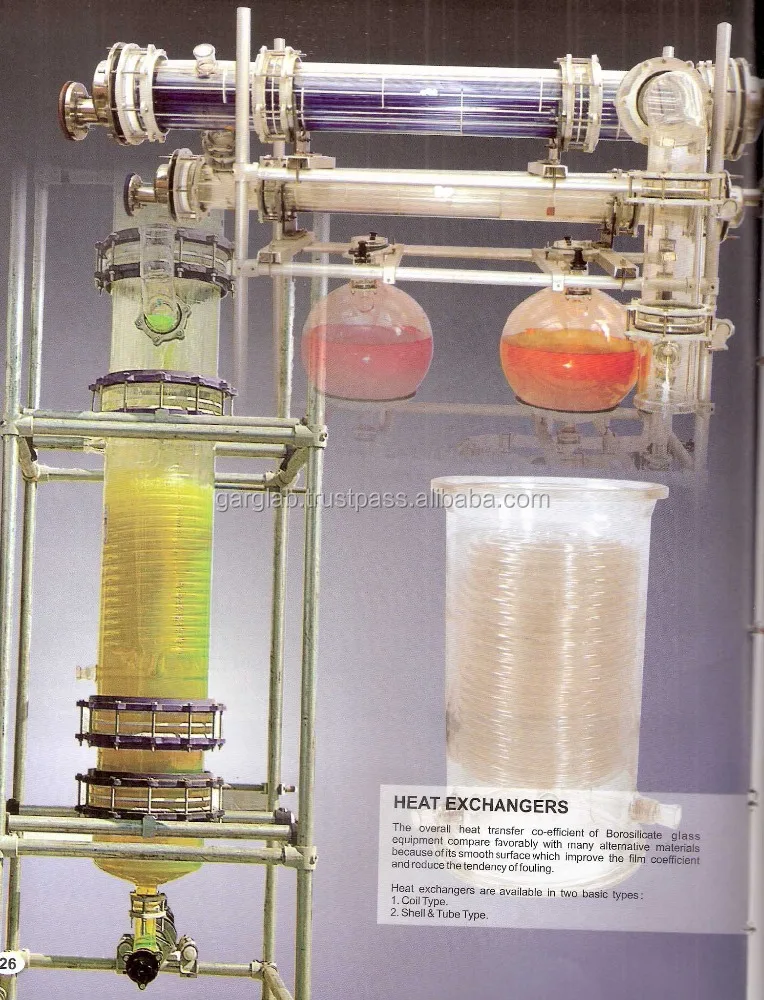

All kind of Glass Heat Exchanger

- Category: >>>

- Supplier: GARG PROCESS GLASS INDIA PRIVATE LIMITED

Share on (117361102):

Product Overview

Description

The overall heat transfer co-efficient of Borosilicate glass equipment compare favorably with many alternative materials because of its smooth surface which improve the film coefficient and reduce the tendency of fouling.

Condensers are used for condensation of vapours and cooling of liquids. Condensers are made by fusing number of parallel coils in a glass shell. Coils are made in different diameters using tubes of different bores.

The average co-efficient of heat transfer in coil condenser is considered as :-

Condensation 200 - 270 Kcal/m2, hr, °C appx.

Cooling 100 - 150 Kcal/m2, hr, °C appx.

Precautions to be taken in use of condensers :

- Vapours should be passed through shell only.

- Maximum pressure of coolant should be 2.7 bars.

- Adequate flow of coolant should be used.

- Steam should not be used in coils.

- Coolant should not be heated to boiling point.

- Coolant control valve should be turned slowly.

- Coolant should be allowed to drain freely.

- Brine can be used in coils in a closed circuit.

- Water main should be connected with flexible hose.

- Ensure no freezing of water remaining in the coils.

- Condensers should be mounted vertically only.

- Condensers can be mounted in series to provide larger surface area.

Immersion heat exchangers are used to control exothermic reaction in glass vessels. They can be used with vessels having wider bottom outlet (type VSR and VSE). These are provide with a central hole through the coil battery so that a special, extended type, stirrer can be fitted which extends to the bottom of heat exchanger and provide through action.

In most applications, cooling water is used in coils (max. pressure 2.7 bar g.), but they can also be used with steam (max. pressure 3.5 bar g.). In latter case the coils must be completely immersed in liquid. Immersions are not recommended for use with products which have a tendency to crystallize.

Product coolers are used for cooling of liquids, typically, for the cooling of distillates from the distillation columns. Unlike coil condensers, in product coolers, product travels through the coil battery and coolant through shell. This provides more resident time to the product to be cooled. For direct connection with distillate lines, all the product coolers are proviede with 25 DN connections.

Welcome to Garg Process Glass

Most important of all, with our knowledge of chemical engineering, mechanical engineering, erection and installation skills we can design turnkey plants for you which are robust, economical, durable and can be maintained with great ease of operation.

Manufacturers and Exporters of :

\t

\tBorosilicate glass equipments

\tLaboratory glassware and research apparatus

\tQVF type glass

\tGlass pump

\tGlass condenser

\tPilot plant

\tGlass pipeline

We Recommend

New Arrivals

New products from manufacturers at wholesale prices