138C 280F Tin Bismuth Alloy Bi58Sn42

- Category: >>>

- Supplier: Dongguan Wochang Metal Products Co. Ltd.

Share on (1600080667943):

Product Overview

Description

Product Description

Product Name | Fusible Alloy | ||||||

Melting Point | Customize any melting from 12 ℃ to 280℃ | ||||||

Available Shape | Ingots/strips/plates,granules/columans/rings/wires/ balls,etc,customize shape | ||||||

Composition Element | Composed of two or more elements from Sn,Bi,Pb,Cd,In,Ga,etc | ||||||

Feature | 1. Accurate melting point,narrow melting range and sensitive reaction | ||||||

2. Good liquidity,excellent spread performance | |||||||

3.Can withstand a certin amount of atmospheric stamping,no deformation,no leakage | |||||||

4.Good compatibility,separate welding and temperature control | |||||||

5.Fast melting time 60 seconds to 120 seconds | |||||||

6.Strong welding strength,can withstand 50kg for 48 hours without falling off and breaking under static hanging after welding into fusible piece | |||||||

OEM service | For custom serivce,please feel free to contact :Tina 0086-13537604101 / sales01_wochang@163.com | ||||||

The Common Fusible Alloy

Approximate Temp in F/C | Bismuth | Tin | Lead | Cadmium | Indium | Gallium | ||||||

54F-66F / 12C-19C | √ | √ | √ | |||||||||

117F / 47C | √ | √ | √ | √ | √ | |||||||

136F / 58C | √ | √ | √ | √ | ||||||||

140F/ 60C | √ | √ | √ | √ | √ | |||||||

144F/ 62C | √ | √ | √ | |||||||||

147F/ 64C | √ | √ | √ | √ | √ | |||||||

158F/ 70C | √ | √ | √ | √ | ||||||||

158F-165F / 70C-74C | √ | √ | √ | √ | ||||||||

203F/ 95C | √ | √ | √ | |||||||||

221F/ 105C | √ | √ | √ | |||||||||

280F / 138C | √ | √ | ||||||||||

Welcome to contact us for further discussing of other alloy.We are waiting for you ! | ||||||||||||

Application

The application field of fusible alloy

Widely used in the parts of electromechanical equipment with temperature control requirements,

such as rockets, ships, aircraft, fire protection, HVAC, refrigeration, valves, electrical, boilers, oil drilling, automotive,

etc.

They are special temperature control material and indispensable for safety equipments.

such as rockets, ships, aircraft, fire protection, HVAC, refrigeration, valves, electrical, boilers, oil drilling, automotive,

etc.

They are special temperature control material and indispensable for safety equipments.

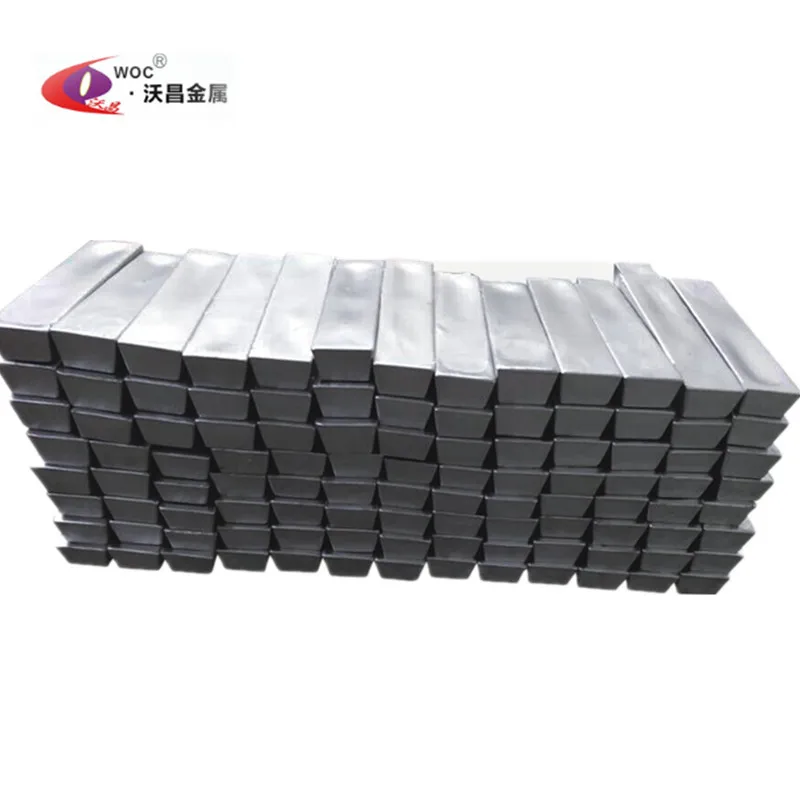

Product packaging

Our Company

Dongguan Wochang Metal Products Co.,Ltd

1.Own 4 production lines(Alloy materials,centrifugal casting,die-casting and CNC)

2.It is one of the few manufacturers in China from alloy raw materials to finished alloy products.

3. Own 10 sets of Zinc Alloy Die Casting Machinery <30-400T>, 2 sets of Lijin Aluminum Die Casting <280-400T>, 6 sets of centrifugal casting equipment, 10 sets of fully automatic Yizumi injection molding equipment <120-280T>, 5 sets of Haitian powder metallurgy equipment<120-280T>

4.Own mold room, spectrum analyzer, fuel injection, polishing, CNC, dripping, tapping, assembly, packaging and other

departments.It alos has 2 sets of large-scale alloy smelting equipment and complete supporting smelting equipments

3. Own 10 sets of Zinc Alloy Die Casting Machinery <30-400T>, 2 sets of Lijin Aluminum Die Casting <280-400T>, 6 sets of centrifugal casting equipment, 10 sets of fully automatic Yizumi injection molding equipment <120-280T>, 5 sets of Haitian powder metallurgy equipment<120-280T>

4.Own mold room, spectrum analyzer, fuel injection, polishing, CNC, dripping, tapping, assembly, packaging and other

departments.It alos has 2 sets of large-scale alloy smelting equipment and complete supporting smelting equipments

Certificates

Related Products

Why Choose Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices