Guangdong progressive die progressive die manufacturer of cemented carbide iron core for air conditioner motor of punch press

- Category: >>>

- Supplier: Tonghe Precision Mold (Changzhou) Co. Ltd.

Share on (1600087864966):

Product Overview

Description

Products Description

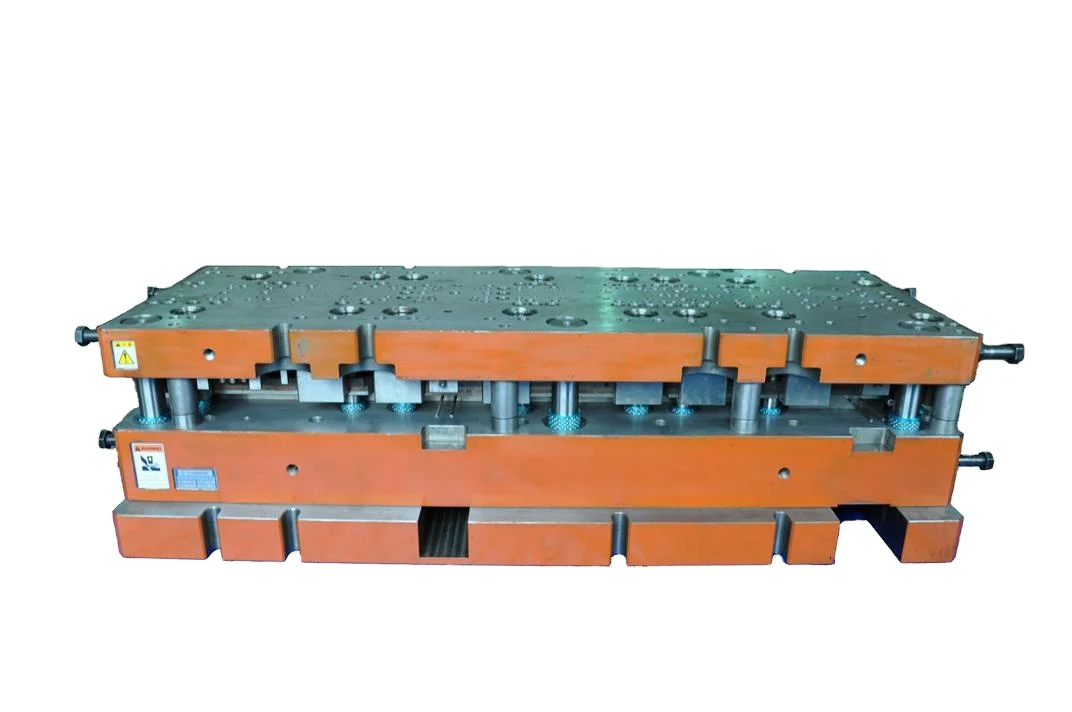

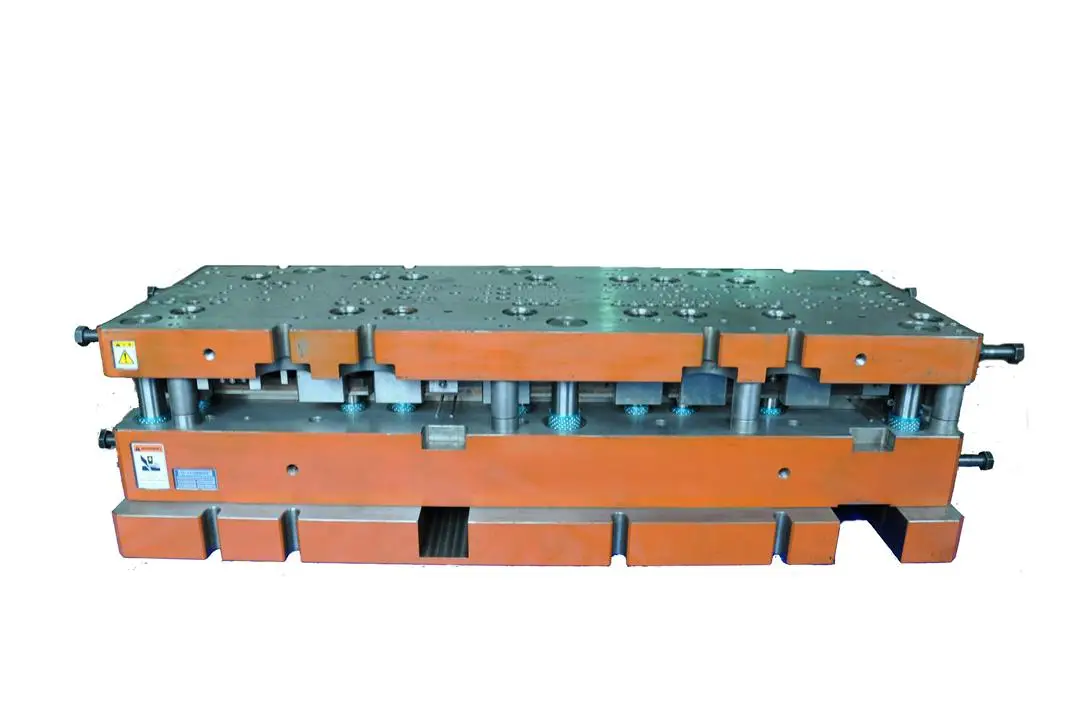

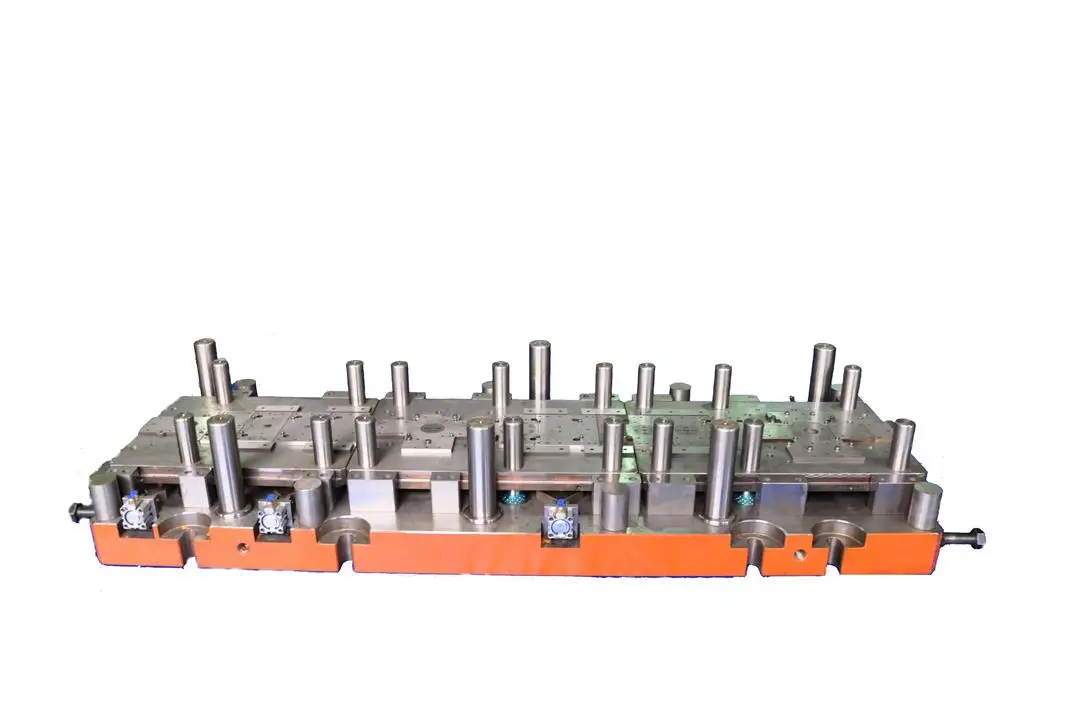

Mold name | Two-row 112mm Rotor and Stator Lamination Stack Progressive Tooling (Indexing) | ||||||||

№ | Project | Project data | № | Project | Project parameters / indicators | ||||

1 | No. of Row | Customizable | 14 | Step Pitch | Customizable | ||||

2 | Strip Width | Customizable | 15 | Concentricity | ≤0.02 for rotor; ≤0.1 for stator | ||||

3 | Comprehensive Tooling Life | ≥0.15 billion strokes | 16 | Lamination Burr | ≤0.05mm | ||||

4 | Blade Life | ≥1.5 million strokes / (0.05-0.12㎜) | 17 | Delamination Strength | ≥10N with stacking concavity point | ||||

5 | Tooling Structure | With inside and outside guide pillars | 18 | Spare Parts Configuration | Optional | ||||

6 | Male Die/Punch Height | ≥55 | 19 | Error Proofing Device | Included | ||||

7 | Female Die Height | ≥25 | 20 | Part Output Type | Optional | ||||

8 | Effective Cutting Edge Height | Male Die≥7mm | 21 | Indexing Pattern | Optional | ||||

9 | Blade Material | Customizable | 22 | Skewing Control Device | Optional | ||||

10 | Slotting Female Die Type | Integrated | 23 | Pulling Tray Control Device | Included | ||||

11 | Stamping Speed in Run-in Period | 150 SPM | 24 | Protective Device | Included | ||||

12 | Stamping Speed in Production | 150-300 SPM | 25 | Production Timetable | Included | ||||

13 | Strip Thickness | δ0.02~δ1 | 26 | key word | punches dies | ||||

Mould information

Tooling Brand | Tonghe Tooling |

Tooling Name | Two-row 112mm Rotor and Stator Lamination Stack Progressive Tooling (Indexing) |

Tooling No. | TM100-031 |

Color | Natural color |

Dimension | 1950x700x435 |

Type | Progressive Tooling, Stamping Tooling, Rotor and Stator, High-speed Stamping Tooling, Loose Lamination Stamping, Skewed Slot, Indexing (Rotation), Rotated and Skewed, Lamination Stack Stamping Tooling |

MOQ | 1 Set |

Yield | 250-300 strokes |

Strip Thickness | &=0.5 |

Material thickness | Equivalent to B50A470 |

Strip Width | 217 |

Step Pitch | 113 |

Material Utilization Ratio | 54.59% |

No. of Row | Two-row |

No. of Cavity | 4 |

Total Steps on Tooling | 16PITCH |

Machine Tonnage (Ton) | 147.42Ton |

Stripping Force (Ton) | 29.48Ton |

Skewing Orientation and Angle | None |

Indexing Angle | 90° for rotor; 180° for stator |

Feed-in Height | 265 |

Shut Height | 435 |

Processing Characteristics | High-speed Stamping, Progressive Tooling, Indexing (Rotation), Skewed Slot, Automatically Stacked |

Quality & Accuracy | +/- 0.002〜0.05mm (tooling precision) |

Measurement Devices and Instruments | Plug Gauge, Quadratic Measurement, 3D Coordinate Measurement, Tensile Tester, Micrometer, Projector, Height Gauge, Scale, Collimator, Deflector, CMM, Concentricity Measurement, etc. |

Application | Home appliances, power tools, industrial automation, automobiles, NEV, toys |

Equipment | Grinding machine, slow- feeding wire cut machine, CMM, gantry boring machine, medium-speed wire cut machine, internal and external grinding machine, milling machine, lathe, jig grinder, flat grinder |

Tooling Feature | Our tooling can perform a variety of functions, such as automatic stamping, automatic stacking, stepped bore punching, automatic skewing and automatic rotation.We can also customize single-row or multiple-row tooling according to customer requirements. Rapid tooling production lead time is our strength, which is far beyond our peers. |

External Grinding Machine

Jig Boring Machine

Medium-Feeding Wire Cut Machine

Flat Grinder

3D Projector

Milling Machine

Jig Grinder

Lathe

Projector quadratic element

Features

It has the functions of automatic stamping, laminating riveting, punching step hole, twisting groove, turning and so on

We are specialized in the design and production of progressive dies for all kinds of motor stator and rotor. The manufacturing accuracy of the main parts of the mold is up to 2um, the step accuracy is within 5um, and the total life is more than 150 million punches. It has the functions of automatic stamping, laminating riveting, punching step hole, twisting groove, turning and so on. And according to customer requirements, according to single row or multi row layout and opening mold, the opening cycle speed is far faster than that of the same industry.

Customize Service

Tonghe Precision Standardization Process as follows

Step 1 | Project Feasibility Analysis conducted according to your requirements (Output: Quotation, Layout, Basic Tooling Parameters) |

Step 2 | Receive your Order Notice |

Step 3 | Prepare Tooling Production Timetable |

Step 4 | Conduct tooling design |

Step 5 | Confirm technical parameters |

Step 6 | Finalize Tooling Layout |

Step 6.1 | Review General Assembly Drawing |

Step 7 | Sign back component drawings |

Step 8 | We prepare materials |

Step 9 | Formulate tooling components machining process |

Step 10 | Tooling components processing, production and procurement |

Step 11 | Assembly (Submit Semi-finished products) |

Step 12 | Wait for your reply and re-debug tooling |

Step 13 | Complete first samples |

Step 14 | Submit first samples, waiting for customer acceptance |

Step 15 | Tooling delivery |

Step 16 | Adjust tooling at Buyer site, and conduct tooling maintenance training |

About Us

Tonghe Precision Mold Co., LTD.is a powerful manufacturer specializing in the design, manufacturing, production, sales and service of progressive tooling for all kinds of motor laminations. It manufactures capable tooling with auto-stacked, auto-skewed and rotary (indexing) rotors and stators in processed cores or loose laminations, and has rich experience especially in design and manufacturing of progressive tooling for stepper motor cores. Our customers include overseas- and Chinese-funded enterprises.

Providing high quality, high efficiency and high lifetime progressive tooling is our mission, and our commitment to our customers.The company is located in Wujin District, Changzhou City, easily accessible as it is close to the Shanghai-Wuhan Expressway, the 312 National Highway and the Changzhou Ring Elevated Highway.

Our servo motor hinge core progressive tooling are well-known in China. We have domestic partners all over the country, and are receiving more and more orders from foreign customers. Our products are exported to the United States, Japan, South Korea, Italy,India, Brazil, to name just a few, and are highly recognized by both domestic and foreign customers.

We specialize in the design and production of progressive tooling for all kinds of motor stator and rotors.

Providing high quality, high efficiency and high lifetime progressive tooling is our mission, and our commitment to our customers.The company is located in Wujin District, Changzhou City, easily accessible as it is close to the Shanghai-Wuhan Expressway, the 312 National Highway and the Changzhou Ring Elevated Highway.

Our servo motor hinge core progressive tooling are well-known in China. We have domestic partners all over the country, and are receiving more and more orders from foreign customers. Our products are exported to the United States, Japan, South Korea, Italy,India, Brazil, to name just a few, and are highly recognized by both domestic and foreign customers.

We specialize in the design and production of progressive tooling for all kinds of motor stator and rotors.

The manufacturingaccuracy of the main parts of the tooling reaches as high as 2μm and the pitch precision can be controlled within 5μm. The tool life attains to above 150 million strokes. Our tooling realize multiple functions such as auto pressure charging, auto stacking, step holes punching, auto skewing, and auto rotation. We can also make single-row or multi-row tooling according to customer requirement. The fast tooling production lead time is way beyond our peers.

common problem

Are you a factory or a trading company?

We are a factory with export permission, located in the Economic Development Zone of Changzhou, China.

How do you monitor and control Tooling quality?

We rely on a standard procedure to monitor and control tooling.

1.8.1 Project feasibility analysis;

1.8.1 Project feasibility analysis;

1.8.2 Project approval;

1.8.3 Project timetable;

1.8.4 Design general assembly drawing (GAD);

1.8.5 Joint review of GAD;

1.8.6 Make drawings and formulate manufacture process;

1.8.7 Manufacture process management and control;

1.8.8 Inspect tooling components;

1.8.9 Tooling assembly (receipt of tooling components from storage);

1.8.10 Stamp samples for testing tooling;

1.8.11 Trial production of small-lot products; 1.8.12 Tooling delivery

How can we accurately understand the manufacturing level of your factory?

The following conditions are the prerequisites for us to make high-quality tooling:

1. High precision equipment;

2. Constant temperature and humidity production environment;

3. A R&D team and a production equipment team composed of experienced experts

1. High precision equipment;

2. Constant temperature and humidity production environment;

3. A R&D team and a production equipment team composed of experienced experts

What are the strong points or features of your tooling?

High precision and long service life are the biggest features of our products.

We have partnered with a large domestic motor manufacturer for a long term. We have supplied it with more than 100 sets of tooling. The service life of each tooling we supplied has greatly exceeded the agreed life. Some of the tooling are still running since its first use.

We have partnered with a large domestic motor manufacturer for a long term. We have supplied it with more than 100 sets of tooling. The service life of each tooling we supplied has greatly exceeded the agreed life. Some of the tooling are still running since its first use.

Do you have a R&D team?

We have conducted cooperative research and development with well-known domestic schools of engineering, and have hired top domestic professors to give us long-term R&D guidance. Our team of engineers have more than ten years of experience in the industry. By virtue of sophisticated equipment, and strict production management, TONGHE’s tooling has a longer life and higher precision, which brings TONGHE high reputation in the domestic industry. Our products speak for themselves. Our tooling can reach the agreed life, even far beyond the agreed life.

How could I acquire samples?

You may buy any of the lamination stack products that are displayed in Ali Shop.

Or you may contact directly with customer service. We will send the samples to you on time for your testing and inspection.

Or you may contact directly with customer service. We will send the samples to you on time for your testing and inspection.

How do you support Tooling once delivered to Customer, especially overseas?

We have established a comprehensive after-sales service system for international customers:

a. Paul Simmonds, the head of TONGHE TOOLING UK Office, who provides services for customers in neighboring countries;

b. Foreign Trade Dept. and Customer Service Department are online providing life-long services, with video conferencing, Skype, WeChat, and Alibaba APP for daily communication;

c. 24-hour face-to-face guidance service via video supported by Chief Engineer of Technical Dept.;

d. We can supply suggested/agreed spare parts that could be considered as vulnerable, small punches, small die parts and re-grinding shims, etc. (We will give reasonable suggestions on spare parts).

a. Paul Simmonds, the head of TONGHE TOOLING UK Office, who provides services for customers in neighboring countries;

b. Foreign Trade Dept. and Customer Service Department are online providing life-long services, with video conferencing, Skype, WeChat, and Alibaba APP for daily communication;

c. 24-hour face-to-face guidance service via video supported by Chief Engineer of Technical Dept.;

d. We can supply suggested/agreed spare parts that could be considered as vulnerable, small punches, small die parts and re-grinding shims, etc. (We will give reasonable suggestions on spare parts).

What is the lead time?

13 weeks for simple tooling and 17 weeks for complex ones.

What are your payment terms?

Payment terms are negotiable and flexible (to a certain degree).

General payment terms: 50% down payment and 50% to be paid upon samples approval before shipment (Balance must be paid before shipment). We accept RMB, USD, Euro and GBP.

General payment terms: 50% down payment and 50% to be paid upon samples approval before shipment (Balance must be paid before shipment). We accept RMB, USD, Euro and GBP.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices