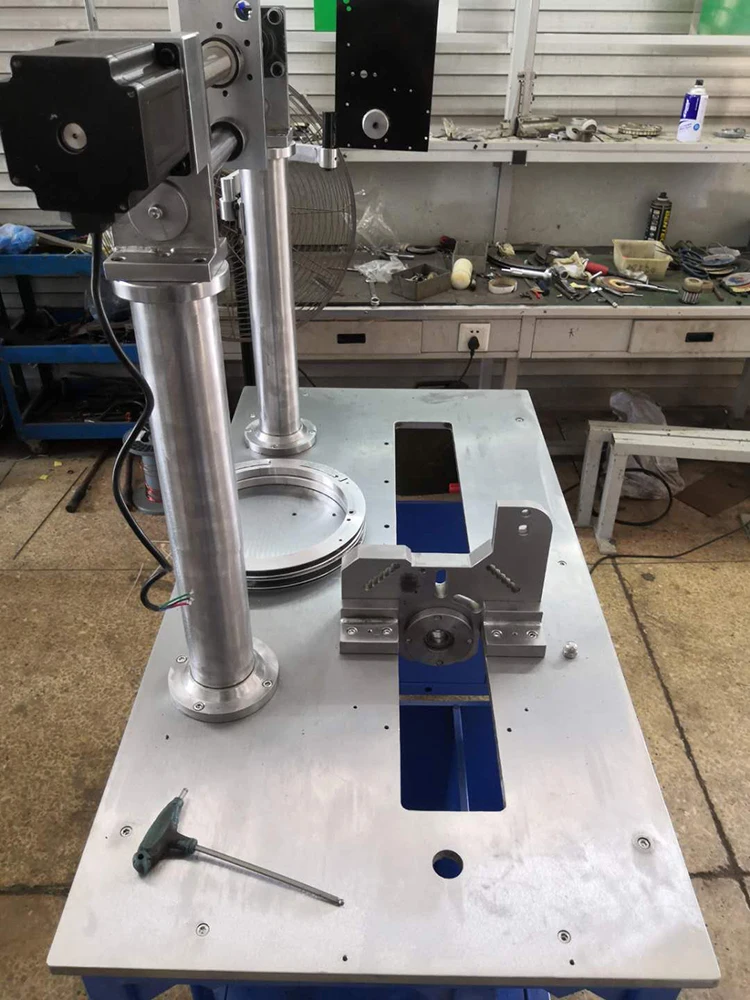

CNC rectangular winding machine for low voltage transformer

- Category: >>>

- Supplier: Shanghai Wenyou Industry Co. Ltd.

Share on (1600088342200):

Product Overview

Description

| Model No. | ZDH-2 |

| Nominal diameter of enameled wire | Φ0.26~1.0mm |

| Max winding length | Φ180mm |

| Max winding width | Φ180mm |

| Winding rotation speed range | 1440rpm |

| Voltage range of application | 0.5~0.66kv |

| Machine tool power | 0.55kw |

| Input power of machine tool | 220v |

| Weight of machine tool | 60kg |

| Dimensions of machine tool | 600*600*1200mm |

Shanghai Wenyou industry co., Ltd. It’s located in Fengxian District, Shanghai, China. The company is specialized in manufacturing, research and development, sales of epoxy resin, insulation materials, transformer winding machine and supporting production equipments and molds. They are not only sold in china, but also exported to Europe, Southeast Asia, Middle East region and Russia and the other CIS countries.

The company has passed management system of ISO9001 and ISO14001,the European Union ”SGS”, and also the United States UL certification. The epoxy products are widely used in indoor and outdoor 10-1100KV high voltage electrical insulation. Insulation part mainly were 12~40.5KV series epoxy resin pressure gel brackets APG molding pressure (SMC/DMC), high and low voltage power electrical equipment supporting insulation parts, grounding switches, components and other products. and production equipments include standard and double or station six sides machine APG clamping machine which were full automatic, servo and PLC touch screen control. The advantage is that the electronic vacuum gauge is more accurate, Triple safety design, oil cycling heating surround pot, heated evenly, thin film de-gassing, excellent vacuumize etc. The Quality of our products is the award-winning in the market, and also established a good reputation for our company.

Wenyou is based on china, serving for global electricity, providing stable products and high quality service to all of the world.

Q: What does “FOB”“CFR”and “CIF”Mean?

A: FOB=free on board with China loading port

CFR=CNF=cost and freight charge with destination port

CIF=CFR+Insurance with destination port

Q: What's consists of equipment for your APG whole production line?

A: APG Machine-APG Mold-Curing Oven-Air compressor-Mixing Material-Release Mould Agent-

Xylene germicides.

Q:What information do we need before quote?

A: Your product's dimension and photo or drawing.

Q: How about your installation & debugging and after-sale service?

A: Our engineer go to the oversea for the installation and debugging availably,and we

provide one-stop sevice and machines lifelong maintenance.On site test and inspection

available.

Q: How about your experience in this field?

A: We have more than 10 years experience in this field.

Q: Is it one-stop service company in electric power equipment industry?

A: Yes,Our products cover APG Clamping Machine, APG Molds & Winding

Machine (CT & PT).

Q: What is your delivery time?

A: It takes around 50 working days.

Q:How's the packing way?

A:The machine with plastic film and others parts use wooden case for safety.

Q: What's the shipping port?

A: Shanghai.

Q: What's the payment terms?

A: Telegraphic transfer(TT), Letter of credit.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices