tianjin bridge welding flux THSJ101 for Submerged arc H10Mn2 welding flux EM12 EM12K AWS F7A0 EH14

- Category: >>>

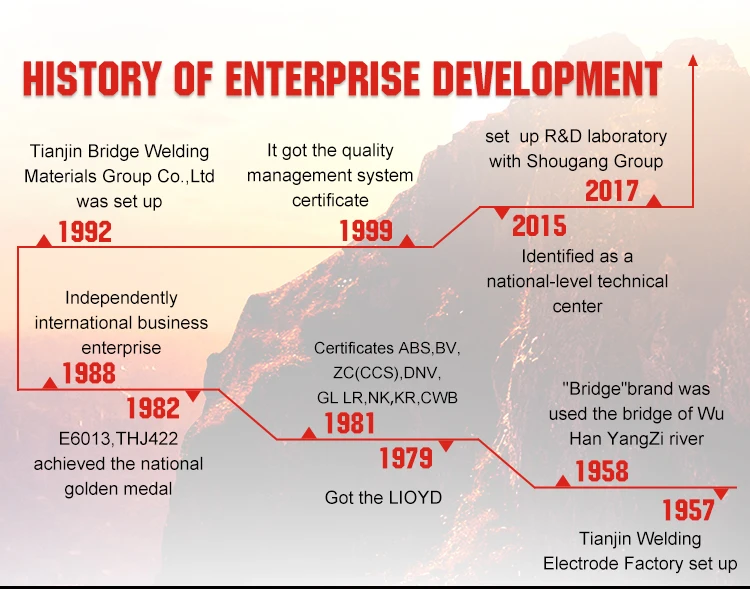

- Supplier: Tianjin Bridge Welding Materials Group Co. Ltd.

Share on (1600091980183):

Product Overview

Description

|

PRODUCT DISPLAY |

| TH-SJ101 |

Sintered flux GB / T 5293 F5A4-H10Mn2 GB / T 12470 F48A4-H10Mn2 AWS A5.17 F7A4-EH14 |

APPLICATIONS:

it can be used in single-channel, multi-channel, monofilament and multifilament submerged arc welding for a variety of low-alloy structural steels with appropriate wires (such as H10Mn2).

CHARACTERISTICS:

TH-SJ101 is a fluorine alkali type alkaline sintering flux with particle size of 10-60 mesh or 10-40 mesh. The alkalinity is about 1.8. It can be used in AC and DC dual purpose. The arc combustion is stable, the slag is easy to be removed, and the welding seam is formed beautifully. The weld metal has a high impact toughness at low temperature.

PRECAUTION:

1. Before using, the flux shall be baked for 2 hours at 300-350 ℃.

2.Do remove rust, oil, water and other impurities in the weld zone before welding.

Mechanical properties of deposited metal: (TH-SJ101/THM-43B combination)

|

Items |

Tensile strength Rm (Mpa) |

Yeild strength Rel/Rp0.2 (Mpa) |

Elongation A (%) |

X ray detection |

Charpy V-notch impact energy (KV2) (J) -40℃ |

|

Standard value |

480-650 |

≥400 |

≥22 |

Ⅰ |

≥27 |

|

Typical value |

525 |

440 |

31 |

Ⅰ |

100 |

Physical and chemical properties of flux:

|

Items |

S(%) |

P (%) |

Moisture content(%) |

Mechanical inclusion(%) |

Mesh |

|

Standard value |

≤0.060 |

≤0.080 |

≤0.10 |

≤0.30 |

10-60 10-40 |

|

Typical value |

0.010 |

0.023 |

0.01 |

0.1 |

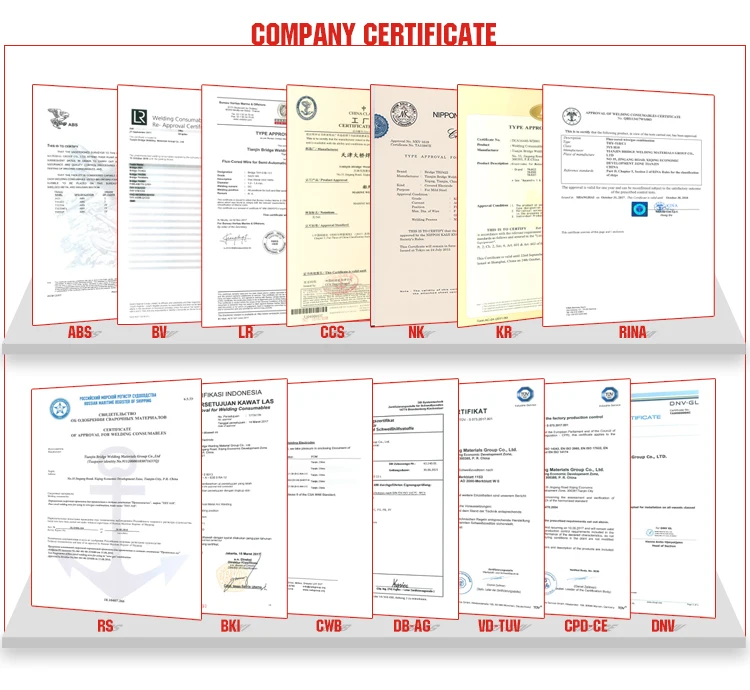

This product has passed China, the United States, Britain, Japan, Italy and Norway classification society approval.

| PRODUCT APPLICATION |

Some of our products have been applied to overseas key projects.

Electrode, SAW wire and flux of 600MPa Grade & 800MPa Grade

applied to hydro steel at Laos pumped storage power station

E6010 cellulose electrode Applied to the Ghana TEMA pipeline project in Africa successfully. It breaks the monopoly of Bohler cellulose electrode and won the bidding of oil pipeline Ghana tank project

| RELATED PRODUCTS |

| Welding Wire | Flux Cored Welding Wire |

| MORE >> | MORE >> |

| ABOUT US |

We are the professional and perfect partner

of yoursin welding consumables.

| F A Q |

Q: what is delivery time / lead time ?

A: 30 days

Q: what is your minimum order ?

A: 5000kgs

Q: what is your payment term ?

A: 1- 30% down payment for order confirmation, 70% before shipment.

2- 100% at sight LC

Q: can we visit your factory ?

A: yes you can at your free time.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices