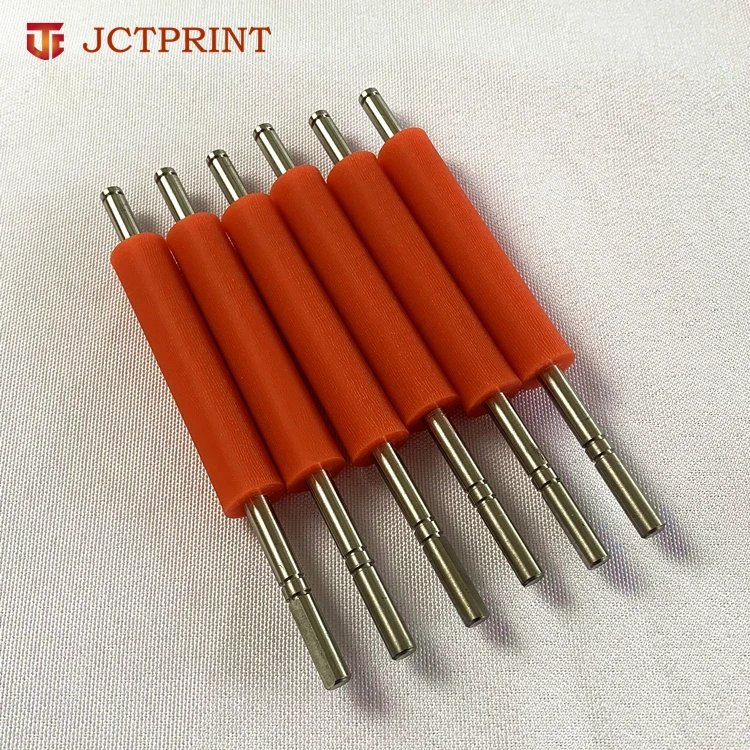

Customized Polyurethane rubber coating roller price

- Category: Printing Machinery Parts >>>

- Supplier: Jinan Jinchangtai Industry And Trade Co. Ltd.

Share on (1600112423050):

Product Overview

Description

Customized Polyurethane rubber coating roller price

1. Specification of rubber rollers

| Size | According To Customer's Drawing |

| Dimension | 10MM-670MM,Length:50MM-8200MM |

| Material | NBR,Silicone,Rubber,Polyurethane,NR,PU FFPM,ETC,EPDM |

| Hardness | 25A-100D |

| Tolerance | 0.05mm |

| Temperature | According customers's requirements |

| Color | Red, Black, White, Clear, etc can do the color base on your pantone NO. |

| Roll core | Carbon steel seamless pipe, 304,316bar |

| Spindle head | 304,316,2Cr13,45steel |

| Application | industrial machine, printing machine and packaging machines and so on |

2. Classification and characteristics of rubber roller

1. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

2. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

3. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

4.Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

5. Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.

3. Advantages of our rubber roller

1. Good wear resistance

Good tensile strength, non-polar solvent, low elasticity, poor thermal tearing performance.

2. Aging resistance

Oil resistance, high temperature resistance.

3. Wide range of applications

Can be applied to paper, dyeing, printing, food processing, metallurgy, plastic processing and so on.

4.Processing Flow of rubber roller

→Chemical test for the raw materials

→Automatic ingredients

→Rolling

→Machining and handling of mandrels

→Rubber coating

→Vulcanization

→Grinding

→Polishing the printing roll

→Laser tester testing

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

Please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.Or you need rollers for famous brand machine,we normally have its drawing,so you just need to tell us your machine model number.

3. What’s your MOQ basis?

1 piece or 1 set,it depends on your actual requirement.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices