160 ton injection molding machine front car grill abs plastic machine spare parts rapid prototype

- Category: >>>

- Supplier: Shenzhen Strongd Model Technology Co. Ltd.Shenzhen Ltd.

Share on (1600134536979):

Product Overview

Description

vacuum forming plastic parts rubber key silicone molding

9 Tips to Reduce Injection Molding Costs:

1. Eliminate undercuts

2. Get rid of unnecessary features

3. Use a core cavity approach

4. Reduce cosmetic finishes and appearances

5. Design self-mating parts

6. Modify and reuse molds

7. Pay attention to DFM analysis

8. Use a multi-cavity or family mold

9. Consider part size

Packing: Wooden Box.

After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation.

Origin: Shenzhen, Guangdong, China.

Package: General Exporting Packing.

Feel free to contact me directly at Skype: Jenniehe518 to get more details

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Brief Introduction

Shenzhen Strongd Model Technology is a marketing leader company, in the Industrial of Design-Prototypes-Mold-Assembly-Shipment. Including the following services: Product Design-Prototype Production-Mass Production.

We cherish our clients ideas most, our aim is to ensure the customers always get the best quality products, services and deliver all the prototyping requirements in time, helping them to develop new products and launch the into the marketplace ahead of their competitors to win more profit.

Strongd would try the best to support your great ideas!

Strongd Service: CNC Prototype (both metal and plastic)-- Vacuum Casting Low Volume (we would suggest

if necessary)--Injection Molding Mass Production

Strongd Impression

This is Strongd Showroom ( where we display the products we've made under the authorization of our clients)

This is Vacuum Casting Workshop ( where we do Low Volume Production work 1-500pcs)

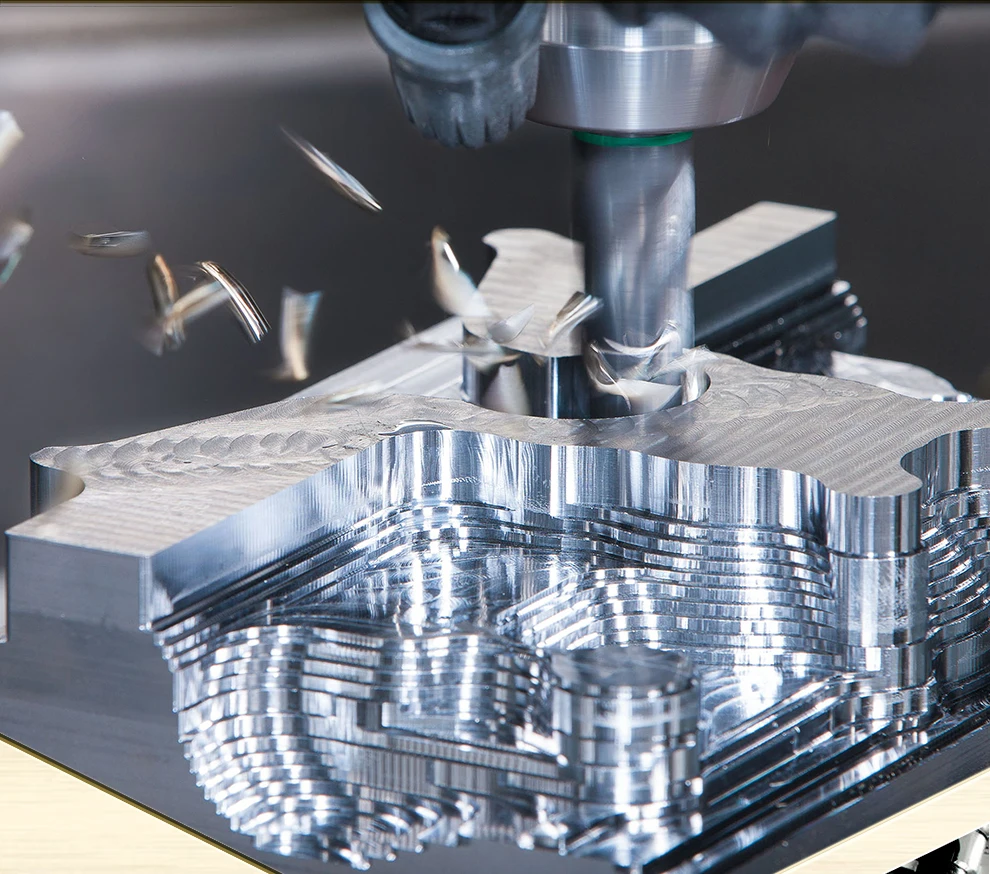

This is Strongd CNC Machining Workshop (where we can do CNC prototype and mass production work: starting from1000pcs)

Strongd Lathe Machining Center for Turning Work

This is Strongd Injection Molding Workshop (Where we could do plastic injection molding work for mass production)

3D Printing Service Automobile Cars Rapid Prototype

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 3-5 days if the goods are in stock. or it is 3-5 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: No, we produce single product sometimes, that's why we don't offer samples.

Q: What is your terms of payment ?

A: Full Payment, balance before shippment.

If you have another question, pls feel free to contact us as below: Jennie He: +8617607616852

Q:How long do you need for making my parts?

A: We have always been dedicated to providing our clients with a rapid prototyping service.As usual,3-5 days is OK.

It will mainly depends on the quantity you need and processing way you prefer.

Q:How will you ship the prototype to me?

A: We will make a best plan to ship the prototype as per its size and material.We generally use DHL/FEDEX/UPS/EMS.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices