Customized plastic transmission 2090 chain plate pp non toxic chain parts

- Category: >>>

- Supplier: Guangdong Nanfang Nylon Products Co. Ltd.

Share on (1600149085347):

Product Overview

Description

Guangdong Nanfang Nylon Products Co. Ltd. , established in 1988 , is a professional production of "Engineering plastics accessories" high tech enterprises . Company have a complete set of imported production equipment and numerical control processing equipments .

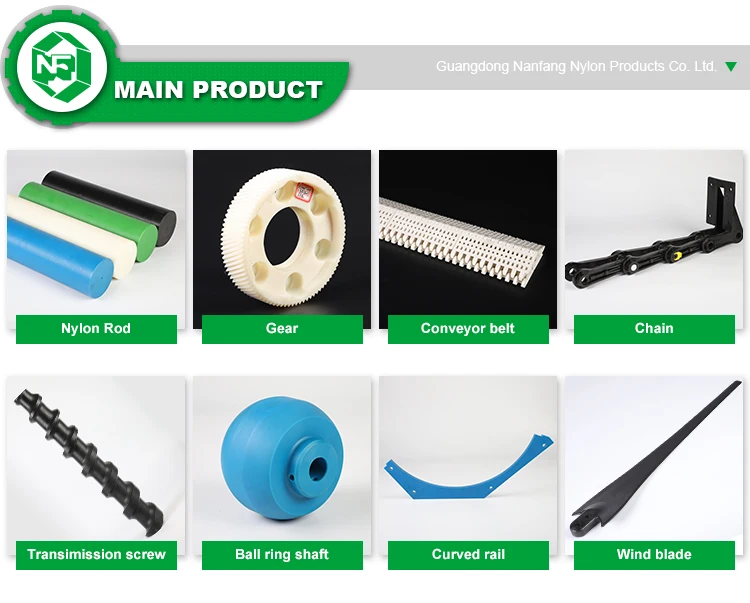

Company main products are : UHMW-PE , MC Nylon , PA6, POM , HDPE , ABS , PU , PC , PVC , PP ,PET, PBT , Acrylic , PEEK PPS, PTFE , PVDF , PAI , PEI , PSU , PI , PBI, Antistatic product series . Copnay strictly enforce ISO9001 international quality certification system.

product description

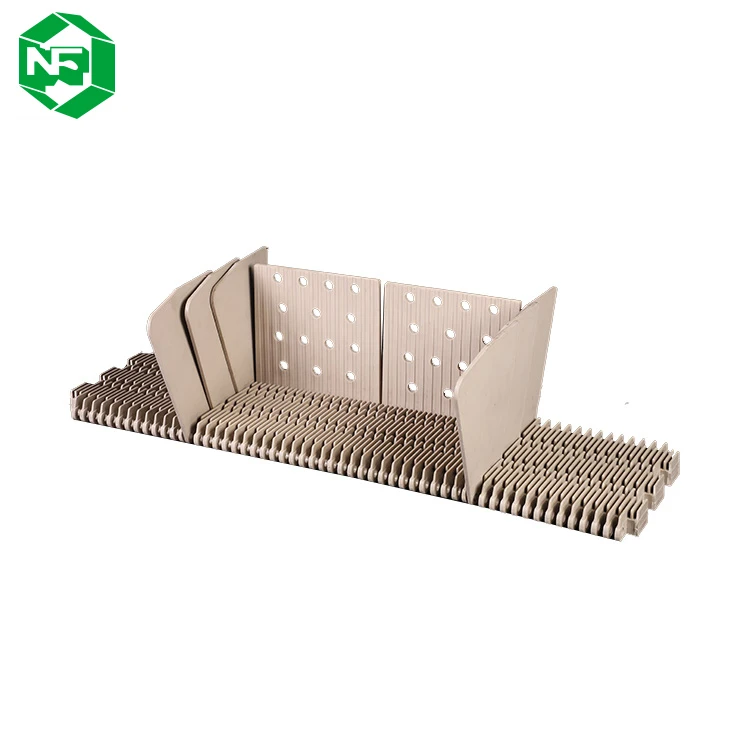

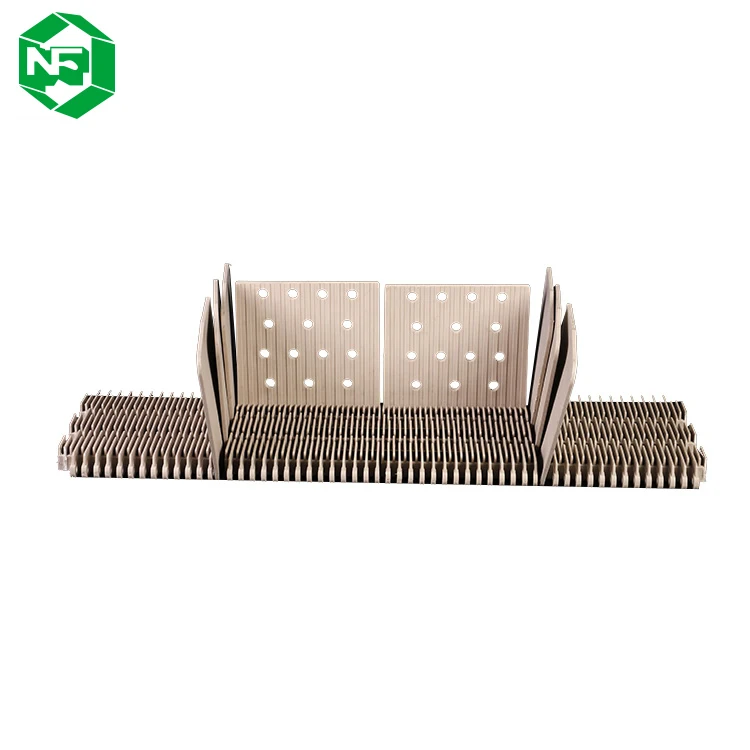

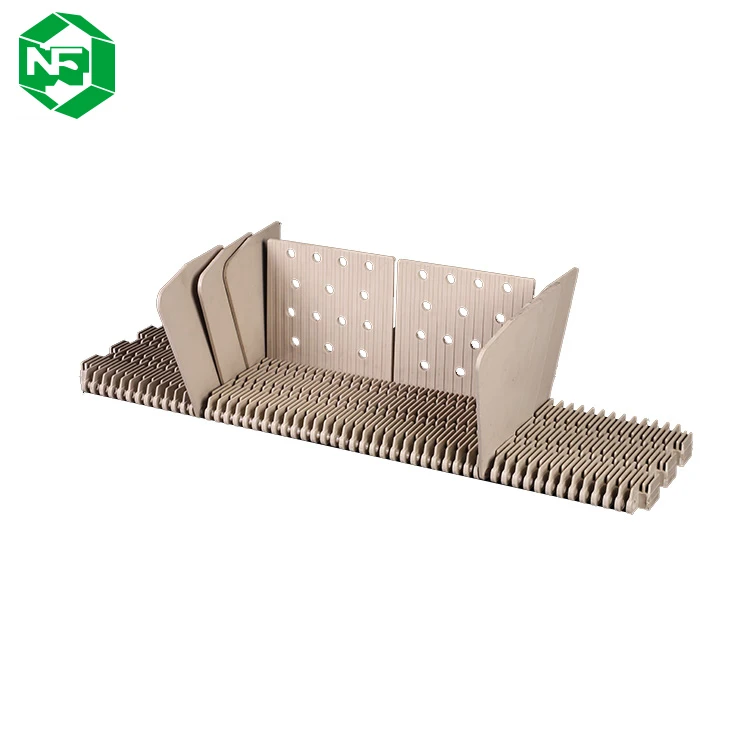

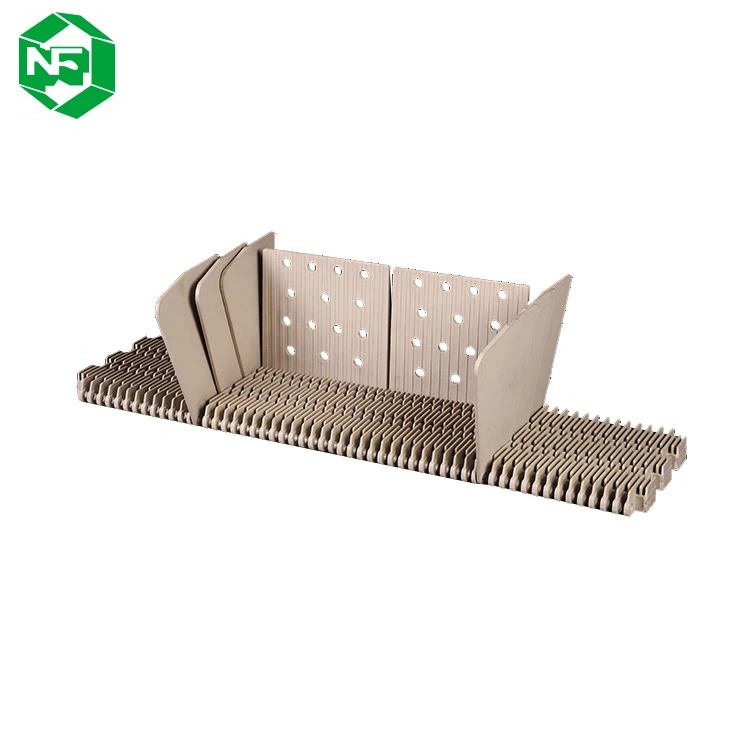

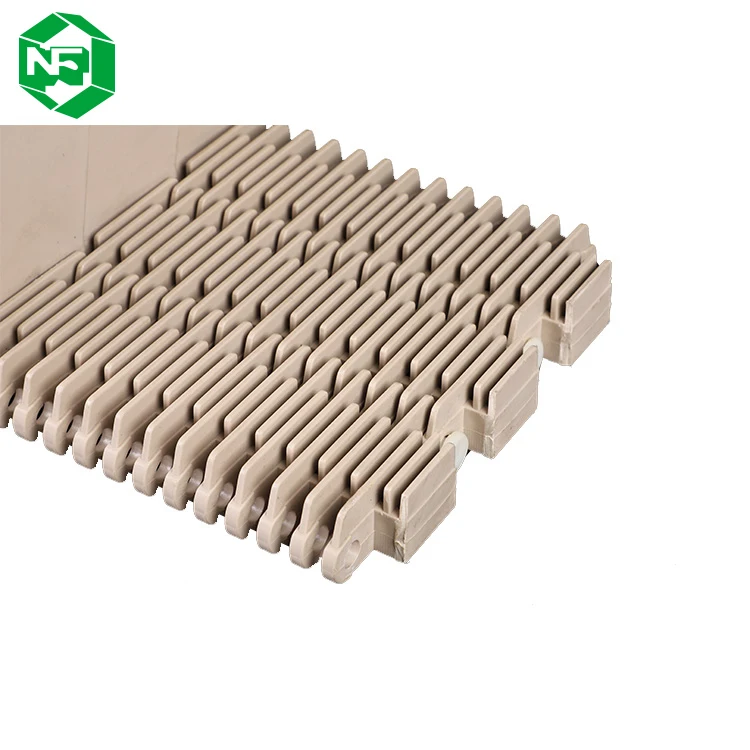

The 2090 type chain plate is a plastic steel chain plate, which is different from the traditional belt conveyor. Its material is a modified pp with excellent fatigue resistance, impact resistance and temperature resistance. Therefore, it overcomes the belt conveyor belt It is easy to be torn, torn, corroded and other shortcomings, providing customers with a safe and simple maintenance method.

2090 type chain plate has the characteristics of 1. easy installation, light weight and low noise; 2. acid and alkali resistance and long service life; 3. self-lubricating and stable operation.

It is widely used in packaging machinery for beverages, beer, food, etc., as well as conveyor machinery in industries such as pharmacy and quick freezing.

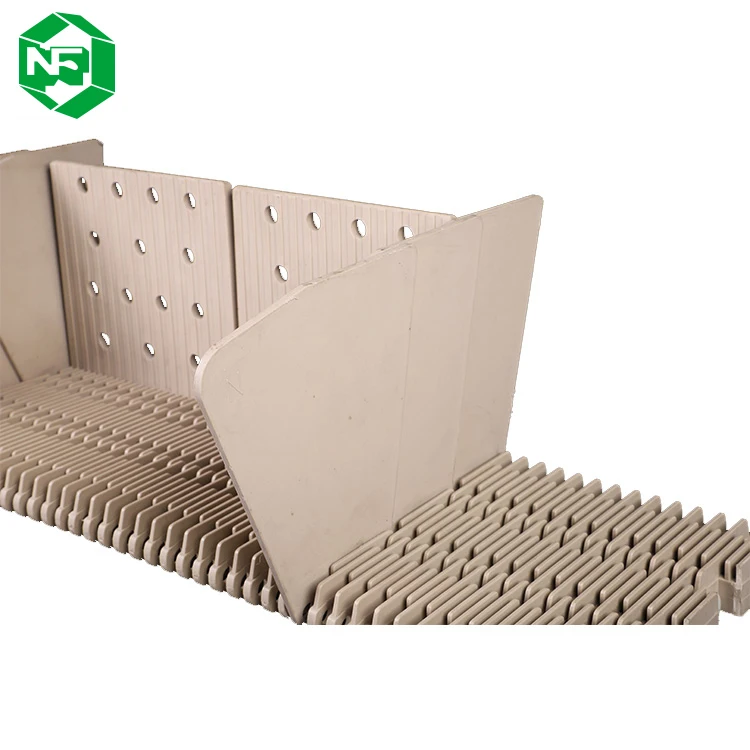

Structural form: horizontal linear conveying, lifting and climbing conveying, turning, etc. 2090 type chain plate conveying and other forms, the conveyor belt can also be equipped with lifting baffle, side baffle and other parts, which can meet various process requirements.

Feature

1. Excellent wear resistance

2. High hardness, toughness and rigidity

3. Excellent corrosion resistance

application

Food packaging machinery, mesh belt conveyor machinery

Click here to see more products

Click here to see more products

Or send your inquiry details in the below, Click "Send" Now !!!

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

The company is committed to manufacture the highest class parts possible, striving to not only meet the requirements of the print, but also making parts that are clean with minimal tooling marks.

Within the factory, the production is run by four workshops, machinery processing shop, injection molding shop, mold shop and material synthesis shop.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

For high volume production, injection molding is the best option. The biggest injection molding machine in shop, has aclamping force of 560 tons, with maximum injection weight of 2 kilograms.

Departing from the machinery processing shop, mold shop is mainly responsible for the production and maintenance of the mold. Offering the strongest backup to the injection molding shop.Full in-house quality check devices can guarantee the parts are built to our customer's specification.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices