Динамический (по методу либа) Портативный твердомер MET D1A электронный модуль, измеритель твердости металла оптом от производителя

- Category: Physical Measuring Instruments >>>

- Supplier: Centre MET LLC

Share on (1600199158049):

Product Overview

Description

Product Description

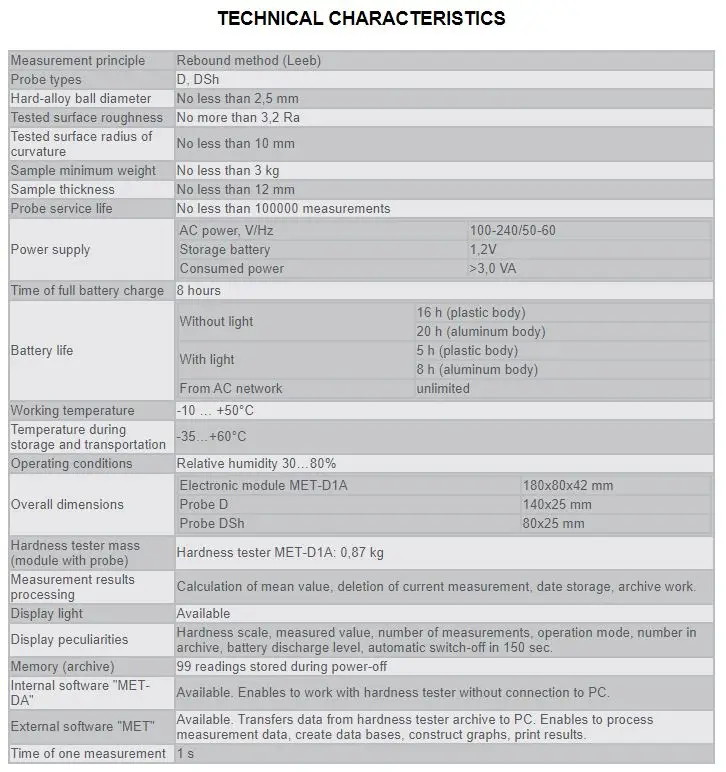

Dynamic (Leeb) Hardness Tester MET-D1A

OPERATION PRINCIPLE

Hardness measurements are based on the determination of the speed ratio of the hammer pin before and after the impact. At its end the pin is equipped with a hard-alloy ball, which is in direct contact with the controlled surface at the moment of the impact. Inside the pin there is a permanent magnet. When the release button is pressed, the pin is thrown onto the tested surface with the help of the previously retracted spring. At that the pin moves inside the induction coil and with its magnetic field creates an electromotive force. The signal from the coil output is sent to the electronic module input, where it is converted into a hardness

value of the selected scale and is indicated on the display.

DISTINCTIVE FEATURES

Operates according to rebound (Leeb) method (ASTM A 956, DIN 50156). The rebound method is very simple, productive and does not require any special experience. It is particularly suitable for hardness measurements on massive articles, materials with coarse-grained structure, forged and cast articles.

MAIN POSSIBILITIES

Measurement of metal and alloy hardness according to standardized hardness scales: Rockwell (HRC), Brinell (HB), Vickers (HV) and Shore (HSD); Availability of three additional scales H1 (HL), H2, H3 for calibration of various hardness scales (for example, Leeb (HL),

Rockwell B, Super-Rockwell, Brinell (HBW), etc.) for hardness control of steel and other metals (for example, cast iron, aluminum, etc.); Use of Rm (MPa) scale for determination of tensile strength (for pearlitic class steels according to GOST 23761); Possibility of hardness control of items that are inaccessible for stationary hardness testers due to their dimensions;

Hardness measurements are based on the determination of the speed ratio of the hammer pin before and after the impact. At its end the pin is equipped with a hard-alloy ball, which is in direct contact with the controlled surface at the moment of the impact. Inside the pin there is a permanent magnet. When the release button is pressed, the pin is thrown onto the tested surface with the help of the previously retracted spring. At that the pin moves inside the induction coil and with its magnetic field creates an electromotive force. The signal from the coil output is sent to the electronic module input, where it is converted into a hardness

value of the selected scale and is indicated on the display.

DISTINCTIVE FEATURES

Operates according to rebound (Leeb) method (ASTM A 956, DIN 50156). The rebound method is very simple, productive and does not require any special experience. It is particularly suitable for hardness measurements on massive articles, materials with coarse-grained structure, forged and cast articles.

MAIN POSSIBILITIES

Measurement of metal and alloy hardness according to standardized hardness scales: Rockwell (HRC), Brinell (HB), Vickers (HV) and Shore (HSD); Availability of three additional scales H1 (HL), H2, H3 for calibration of various hardness scales (for example, Leeb (HL),

Rockwell B, Super-Rockwell, Brinell (HBW), etc.) for hardness control of steel and other metals (for example, cast iron, aluminum, etc.); Use of Rm (MPa) scale for determination of tensile strength (for pearlitic class steels according to GOST 23761); Possibility of hardness control of items that are inaccessible for stationary hardness testers due to their dimensions;

Availability of archive and software for PC connection.

Detailed Images

Packaging & Shipping

Packaging Details | Carton Box |

Processing Time | 5 days |

Port | St. Petersburg |

MOQ | From 1 pcs |

FAQ

Are the hardness blocks supplied with a calibration certificate?

You can choose the factory calibration certificate or the FSUE "VNIIFTRI" calibration certificate. This certificate is issued by the main hardness center of Russia - a metrological institute FSUE "VNIIFTRI" which is a delegate from Russia during international comparisons (//vniiftri.ru/index.php/en/).How to quickly determine the type of hardness tester?

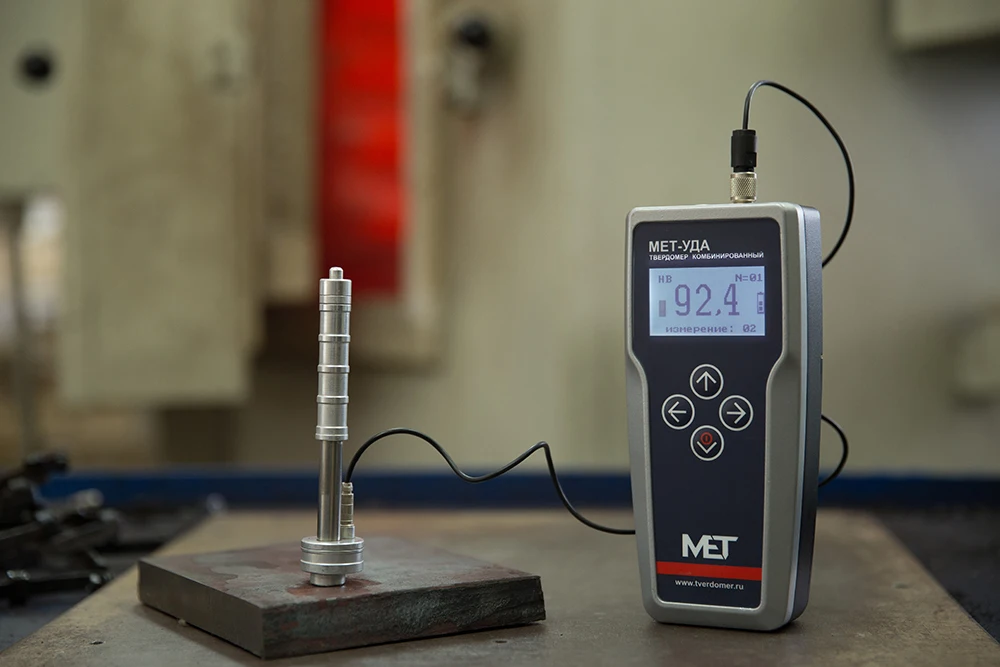

It depends on the size of the measurement object. If the mass is less than 3 kg or the wall thickness is less than 10 mm, then you need to choose UCI - MET-U1A. If the weight is more than 3kg and the thickness is more than 10mm, then you can use the dynamic MET-D1A. If you have different details, it is better to take the combined MET UDA.

Does the surface to be measured need to be cleaned?

Yes, but it is enough to grind the part with a portable grinder to remove scale, paint, rust.

About Company

Centre MET LLC

Center "MET" is a Russian developer and manufacturer of high- precision portable hardness testers and hardness test blocks since 1998 We are located in Moscow, Zelenograd.

Hardness testers and reference hardness test blocks produced by Centre "MET" reproduce Rockwell, Brinell, Vickers and Shore hardness scales.

Portable hardness testers: ultrasonic (UCI) MET-U1A, dynamic (Leeb) MET-D1A, and combined (UCI+Leeb) MET-UDA, as well as miniature ultrasonic hardness testers MET-MINI allow to perform true and reliable hardness control of articles made of metal.

Reference hardness and micro hardness test blocks are the only means of measurement that enables to calibrate the hardness tester and confirm the correctness of its measurements.

Calibration of MET hardness testers and reference hardness test blocks is carried out by National Metrological Institute of Russia that accredited for providing world famous CIPM calibration.

As center "MET" produce its own production, we control every stage of the manufacture of our testers and hardness blocks. Thus, we can guarantee the high quality of our products.

MET series hardness testers are calibrated only using standard hardness test blocks HR, HB, HV, HSD and so on without using conversion tables, which are "hardwired" into the programs of other hardness testers that increase the measurement error. However, conversation function is also include into electronic module IP66.

MET series hardness testers are calibrated only using standard hardness test blocks HR, HB, HV, HSD and so on without using conversion tables, which are "hardwired" into the programs of other hardness testers that increase the measurement error. However, conversation function is also include into electronic module IP66.

If you need a non-standard solution for your task, we are ready to help you with pleasure, because we have extensive experience in implementing different projects and passion in hardness science.

Certification

We Recommend

Portable Stature Meter wall mounted height gauge Microtoise meter

US $45.00-$55.00

BNENTECH digital anemometer GM 816 in the market with low price

US $40.00-$50.00

New Arrivals

New products from manufacturers at wholesale prices