200mm diameter Small standard laboratory vibrating test sieve shaker machine with 1 5 layers

- Category: >>>

- Supplier: Xinxiang Gaofu Machinery Co. Ltd.

Share on (1600202221304):

Product Overview

Description

The S49- 200 laboratory standard testing sieve is the economical alternative of the series with familiar GAOFU quality and

reliability. It features digital setting and display of performance and time.

Feature

1. NEW: digital display of performance and time

2. Suitable for dry and wet sieving

3. Excellent separation efficiency even with short sieving times

4. Efficient electromagnetic drive

5. 3-D throwing motion which ensures optimum use of the open sieve area and lets the sample move equally over the whole sieving surface

6. Screen frame up to 510 mm height

7. Free adjustment of all process parameters (time, performance)

8. Optional comfort clamping device

9. maintenance-free,easy operation, ergonomic design

Name | Lab test vibrating sieve |

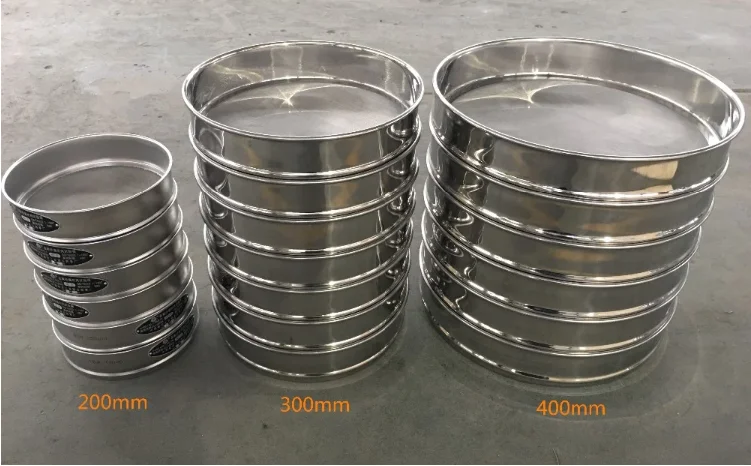

Diameter(mm) | 200mm,300mm |

Layer | 1/2/3/4/5 layers for option |

Frequency (n/min) | 1400 |

Amplitude (mm) | 1-4 |

Force (KN) | 3 |

Chassis level (mm) | ≤0.6 |

Power (KW) | 0.18 |

Motor speed (r/min) | 1400 |

Dimensions(mm) | 370(L)×350(W)×650(H) |

Timing (min) | 1-15 |

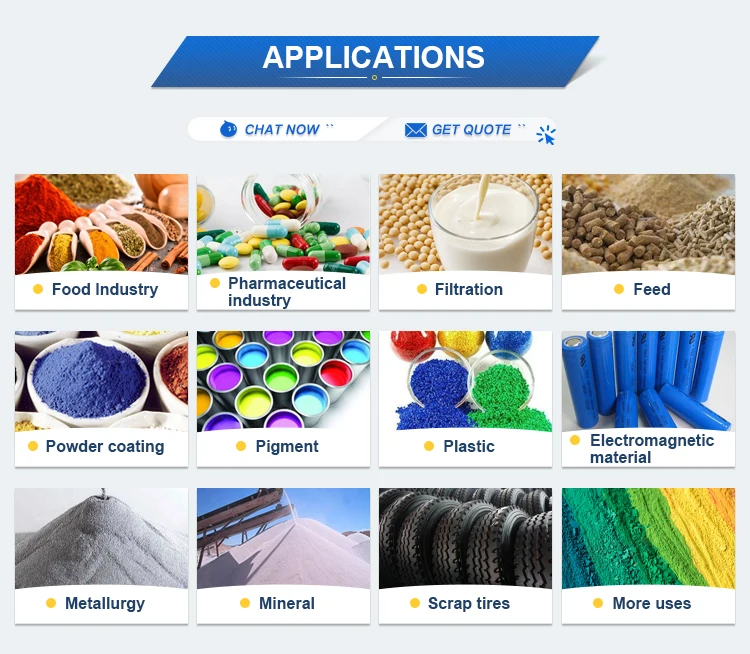

Application:

Food industry : coffee,flours, grains,nuts,

Angricultrure: fertilizers, seeds ,etc

Please confirm the following questions and tell us, then we can send you accurate quotation soon, including additional discount!

Your email address and telephone will not be shared or published!

The proper selection of the vibrating screen depends on the material, mesh size, output required, method of input, abrasiveness of the material etc:

1. Material : _____

2. Moisture:_____%

3. Capacity:________ kg/ hour

4. Screen layer:_______(1-5 layers for option)

5. Screen mesh size:______ mesh . ______ mesh. ______ mesh

6. Voltage:______V, Frequency:______HZ, ___ phase

7.Your special requirement ______________.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices