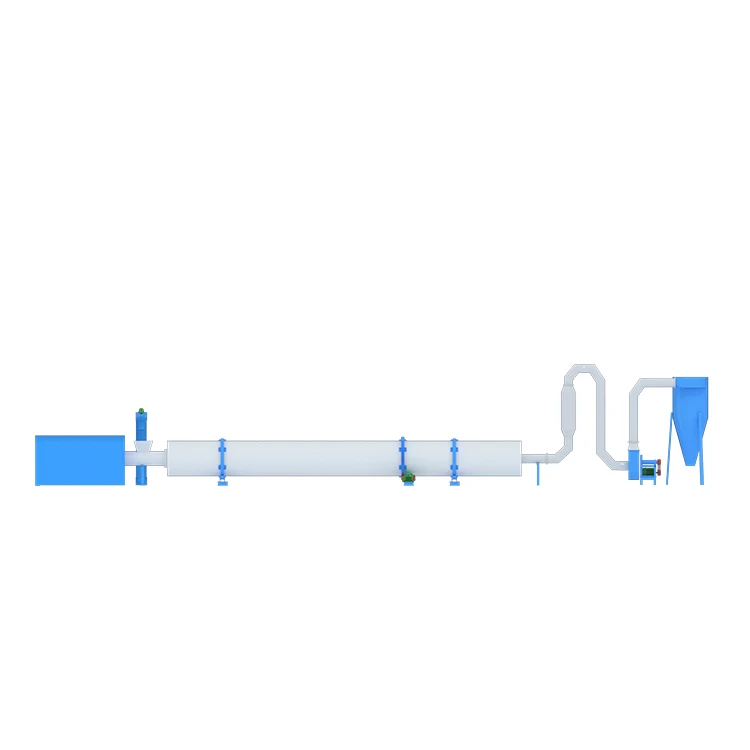

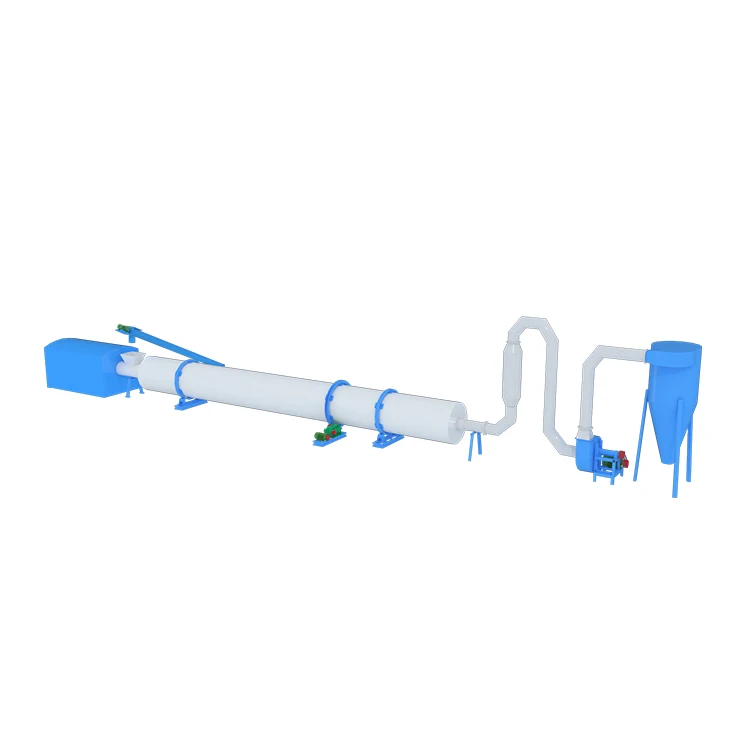

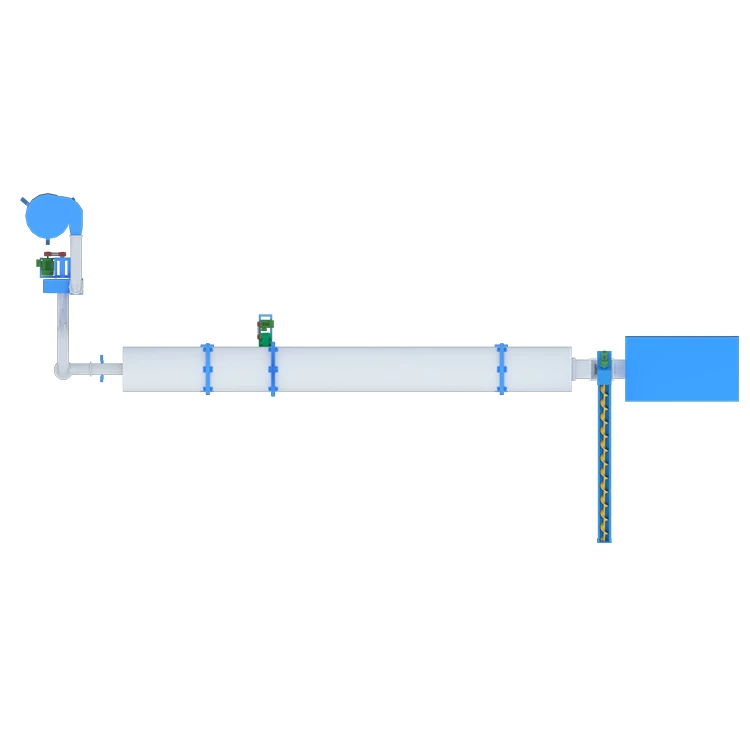

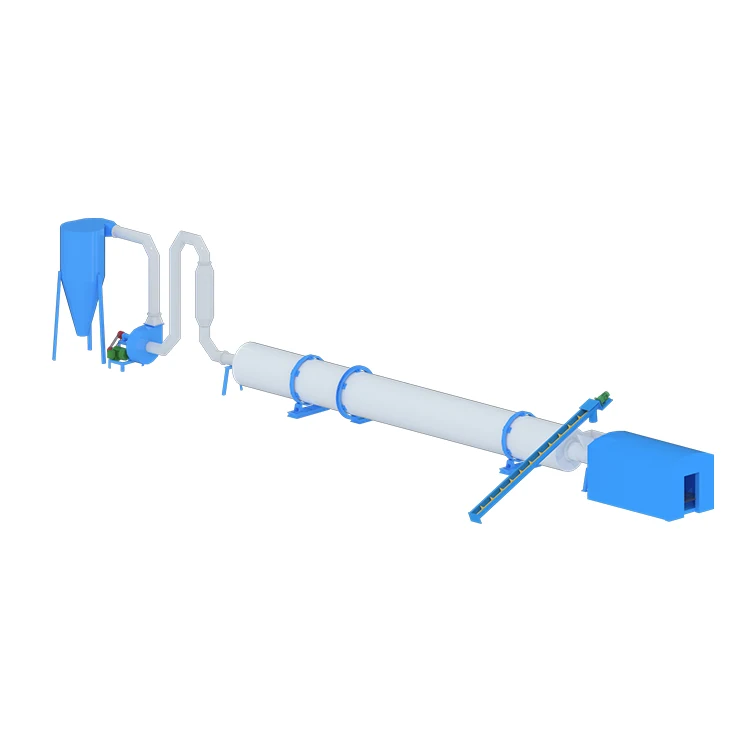

high temperature revolving cylinder drum dryer silica sand browncoal wood sawdust rotary drum dryer

- Category: >>>

- Supplier: Zhengzhou Shuliy Machinery Co. Ltd.

Share on (1600301804634):

Product Overview

Description

Products Description

Heat pumo's drying process is a huge energy-consuming process. According to statistics, in most developed countries, the energy consumed for drying accounts for the country's total energy consumption, and the thermal efficiency is only 25%-50%, and most of the drying The process especially affects heat-sensitive materials (such as food and biological materials) on its color,nutrition, flavor and organization. The heat pump drying technology has the advantages of low energy consumption, low environmental pollution, high drying quality, and wide application range. Its excellent energy-saving effect has been proved by various experimental researches at home and abroad.

Before Drying & After Drying:

Heat pump dryer machine is suitable for many kinds of materials,involved in every aspect of our life, has formed a very wide range

of applications and considerable industrial chain.Popular materials and final products as following:

Before Drying & After Drying:

Heat pump dryer machine is suitable for many kinds of materials,involved in every aspect of our life, has formed a very wide range

of applications and considerable industrial chain.Popular materials and final products as following:

Working Principle& Structure

High temperature heat pump drying and dehumidifying unit in the compressor to complete the gaseous pressure rise and temperature process (the temperature is as high as 100-0, it enters the machine to release high temperature heat to heat the air in the drying room, at the same time, it is cooled and converted into liquid flow, when it runs to the outside machine, liquid rapidly heat absorption and evaporation into gas again,At the same time the temperature can drop to -0-C - 10°C, then the air around the heat absorber will continue to transfer heat to the refrigerant.The heating efficiency of high temperature heat pump drying unit is much higher than that of other heating equipment.

It can be seen that the use of high temperature heat pump drying unit as a drying device can save energy, and also reduce the emission of pollutants such as C02:, to achieve the effect of energy saving and emission reduction.

Parameters

Model | SL-1 | SL-2 | SL-4 | SL-6 | SL-8 |

Number Of Plate | 24 | 48 | 96 | 144 | 196 |

Motor | 9kw | 12kw | 18kw | 22kw | 30kw |

Area Of The Plates(㎡) | 7.62 | 11.52 | 23.04 | 34.56 | 46.08 |

Productivity | 50kg/8h | 100kg/8h | 200kg/8h | 300kg/8h | 400kg/8h |

Demension(m) | 1.55*0.8*2.2 | 2.1*2.1*2.3 | 2.1*2*2.3 | 2.6*2.1*2.3 | 4*2*2.3 |

Different trays

Function

We Recommend

New Arrivals

New products from manufacturers at wholesale prices