GGSCX 1000 seeds sowing machine 1000 trays per hour hihg efficiency seeder machine for foam trays with factory price

- Category: >>>

- Supplier: Jiangsu Grow-Green Agriculture Science And Technology Co. Ltd.

Share on (1600318994044):

Product Overview

Description

GGSCX-1000 seeds sowing machine 1000 trays per hour hihg efficiency seeder machine for foam trays with factory price

Soil-filled, holes-pressed, seeds-sowed, soil-filled (second, covering the seeds) and watering can be completed on this production line. PLC program controlled, human-machine touch screen operation, Sowing speed: 1000 trays per hour

Production line technical parameters | |

Model | GGSCX-1000 (FOAM TRAY) |

Size | 6810*1089*1757 |

Seedling tray specifications | International standard size54*28cm(32—288Interchangeable seedling trays) |

Sowing range | Spherical,Non-spherical0.1-5.0mm size(No fluff on the seed surface, no need to pelletize) |

Sowing method | Needle seeding |

Seeding accuracy | Spherical seeds≥95%,Non-spherical seeds≥90% |

Sowing efficiency | 1000tray/hour |

Seedling tray specifications | Sample |

Sprinkle | Suction type, with blowing Double-station fully enclosed structure, adjustable water volume, equipped with drain pan |

| Main material specifications of automatic seeding system |

Fan | Taiwan KIMPO high vacuum fan |

Power supply | Standard two-phase power supply 220VAC 50HZ |

Matrix loading bin | 1.5 stainless steel plate |

| Sawtooth conveyor belt, stainless steel conveyor belt shaft diameter 101mm |

Frame | 45x75x2.0 stainless steel square tube, side plate 1.5mm stainless steel plate |

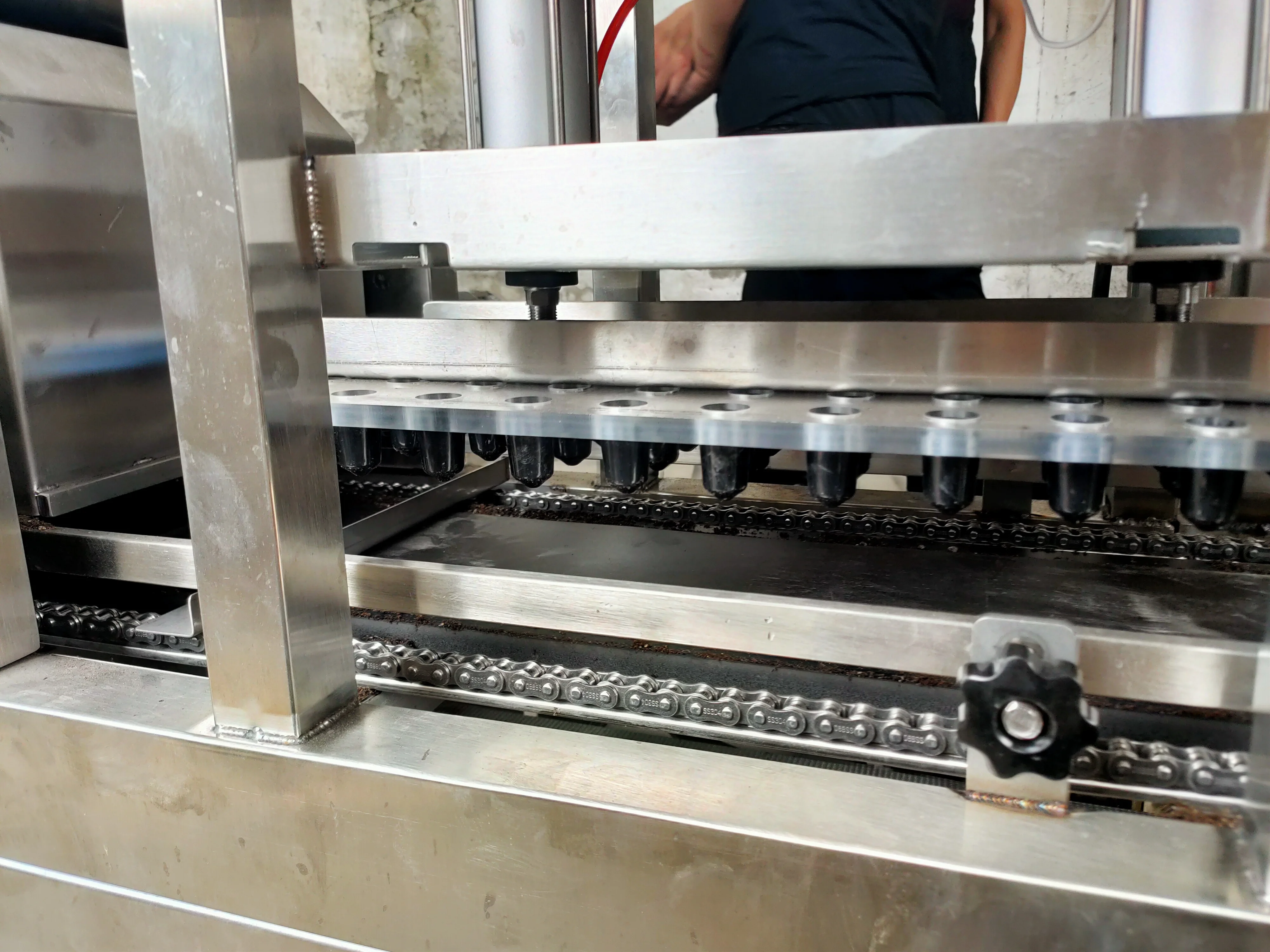

Conveyor chain | Stainless steel 08B chain, plus side plate, 1.5mm stainless steel baffle |

Bottom plate | 20mm thick pvc foam board |

Seeding system | 1.5mm stainless steel plate, 2.5mm stainless steel plate for track plate |

Power system | Xinjie 0.75KW servo + Shengbang 0.75KW reducer |

DETAILS:

First step: foam tray loading automatically

Second step: soil-filling automatically

Third step: hole-pressing and seeds sowing automatically

Fourth step: covering the seeds by by soil automatically

Fifth step: watering automatically

Overview

This Vacuum Plug Tray Precision Seeder is designed and produced according to the

actual request of domestic vegetable flower seedling production, research and development. It fully meets the technical request of seed planting from large and medium-sized seedling

production enterprises, agricultural production cooperatives, private farms and flower production

base. It greatly increases the efficiency for plug tray seedling planting and seedling productivity. It also greatly reduces the labor costs in planting seedling production.

This Plug Tray Seeder is easy to operate. Users only need provide 220v universal power and it can work immediately, no need professional maintenance staff. The machine is small size, light weight, flexible operation and simple structure. Completing hole pressing /seed

sucking/seed sowing continuously.

1.750w high quality turbo fans with strong suction power.

2.Main structure is made of high-quality stainless steel.

3.According to different seeds and sowing requirement, it will be equipped with corresponding

sowing plate and the suction needles. The machine is applied to the biggest seeds like pumpkin,

peas, corn, peas, melons, etc., the smallest seeds like petunias (tens of thousands of grain per

gram), celery, cabbage, etc. and conventional seeds like hot pepper, tomato, grass, etc.

4.The optional sowing plates can match international standard 54*28cm plug tray with 288, 200,

128, 105, 98, 72, 50, 32 holes. (This machine is specially equipped with full set of plates for 288

holes, 200 holes and 105 holes. For big seeds like pumpkin seed, please use 105-hole and

below plug tray)

5.One tray at a time while sowing. Sowing speed 400-500 trays per hour. Sowing rate: 95% - 98%.

Full Tray Seed Sucking and Sowing

Faster and accurater

Packing and Delivery

DIFFERENT SEEDER MACHINE MODELS ARE AVAILABLE:

CUSTOMIZED SERVICE:

DIFFERENT SPECIFICATIONS NURSERY TRAYS CAN BE USED ON OUR SEEDER MACHINE (SOWING MACHINE)

AND WE ALSO MANUFACTURE PLASTIC NURSERY TRAYS FOR CUSTOMERS:

FOAM NURSERY TRAYS CAN BE USED ON OUR SEEDER MACHINE :

PS Nursery Trays to Ship together

Contact us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices