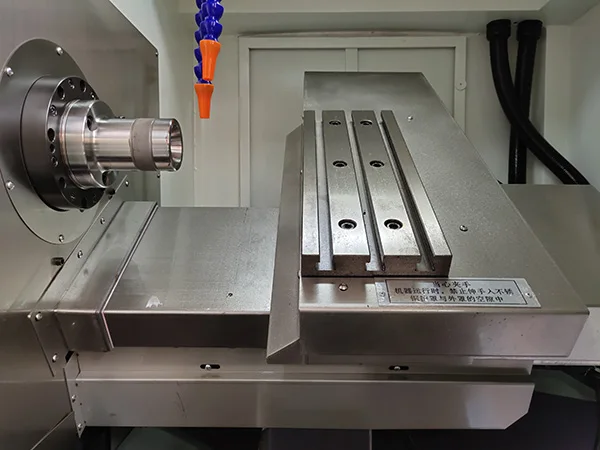

CNC lathe with U turn function easy operate affordable price metal lathe cnc turning lathe

- Category: >>>

- Supplier: Shenzhen Tobest Industry Co. Ltd.

Share on (1600320100325):

Product Overview

Description

TOBEST automatic CNC lathe machine for diameter 25 mm machining length 180 mm

Features:

It is suitable for the mass production of copper, iron, aluminum, and stainless steel bars within 25mm, and the automatic feeding batch production of forgings and other pellets within 50mm.

Using multiple patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a unilateral cutting amount within 2mm, accuracy tolerance within ±0.01mm, and finish 1.6.

It is widely used in the upgrading of hard-track CNC lathes, cam automatic lathes and hydraulic lathes to realize automated production to save labor costs and improve product quality.

Technical parameters:

Processing conditions | Normal use | Max |

Through hole diameter | φ25mm | φ25mm |

precision tolerance | ±0.01mm |

|

machining finish | 1.6Ra |

|

unilateral cutting amount | 2mm | 3mm |

spindle speed, | 3500r/min | 4000r/min |

pellet clamping diameter | φ40mm | φ50mm |

machining length | 180mm |

|

X-axis stroke | 500mm |

|

Z-axis stroke | 180mm |

|

rapid traverse speed | 20m/min | 30m/min |

swing diameter | φ350mm |

|

tool post center height | 40mm |

|

with supporting nozzle Machining length | 120mm |

|

square knife specifications | O16mm |

|

Normal use | Parameter |

machine tool form | 30° inclined bed |

tool form | gang tool |

guide rail form, | 25 linear guide |

screw rod | 25 ball grinding precision level |

spindle unit, | self-made high-speed matching bearing unit spindle |

spindle nose form | A2-4, |

base form | heavy-duty anti-deformation patented frame, |

ground to spindle center height | 1080mm |

machine size (length * width * height) | 1400*1200*1650mm |

machine weight (approximate weight,) | 1500kg, |

spindle motor | 2.2 kW-4 pole frequency conversion motor |

X/Z axis feed servo | 1kW servo |

CNC system, | KT820Ti, |

total machine power | 3.5kW |

clamping method | hydraulic clamping |

Products display

Our customers :

We Recommend

New Arrivals

New products from manufacturers at wholesale prices