Top Famous Brand Spare Parts Fresh vegetable cooling vacuum chiller cooler machine for farm

- Category: >>>

- Supplier: Dongguan Coldmax Refrigeration Equipment Co. Ltd.

Share on (1600325596246):

Product Overview

Description

Commercial Iceberg Rapid Cooling Fruits Feezer Processing Equipment Vacuum Cooler For Compact Vegetables

Product Detail

| Name | Vacuum Cooling machine |

| Processing time per cycle | 20~30mins |

| processing per cycle | 500kg~6000kg |

| power requirements | 380V-50Hz-3Ph or others |

| Compressor | Bitzer/Hanbell |

| Door | Hydraulic system door |

| Vacuum pump | LEYBOLD/Bush |

| Condensing type | Air cooling, Water cooling,Evaporative cooling |

| PLC control system | LG |

| Product Keywords | iceberg Rapid cooling equipment,fruits cooler feezer,vacuum processing equipment |

Features:

1. Brand: COLDMAX

2. Origin: Made In China

3. HS Code: 841869

4. Vacuum chamber inner size: L*W*H=2.6*1.4*2.2m;

5. Door type: Hydraulic door

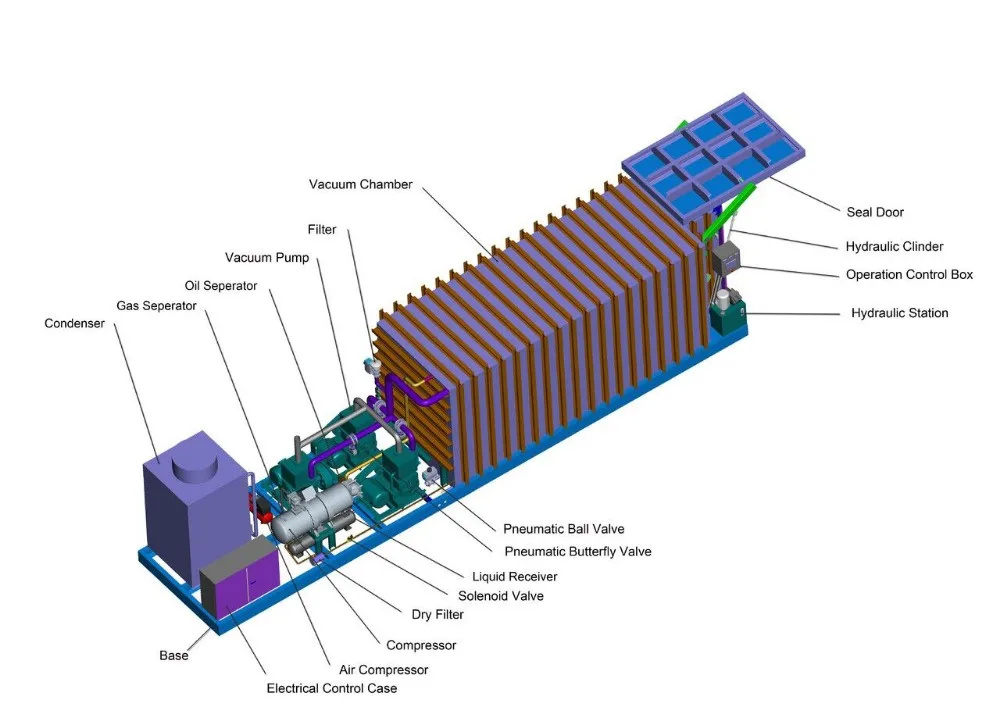

Vacuum Cooling Machine

Vacuum Cooling Machine is the quickest and most cost-efficient cooling system for vegetable, fruits, flowers & more. Vacuum Cooling Machine which can strongly improve your product quality and at the same time reduce your cooling costs, is now becoming an acceptable investment for almost all vegetable growers! Coldmax Vacuum Cooling Machine cools fresh produce based on the principle of evaporation cooling: The moisture evaporates and takes heat away from the fresh produce when the atmospheric pressure is reduced below the boiling temperature of water. This method can cool packed produce quickly and uniformly in large loads (usually in 20 to 40 minutes)

Vacuum Cooling Machine Features

1.Patent in core technology | 6.Plug-in type terminal |

2.Top brand compants | 7.Trouble shooting assist system |

3.Touch screen operation | 8.Digital processing time display |

4.Operator level password | 9.Plentiful tailor made options |

5.Plug& play model available | 10.Compact size |

Vacuum Cooling Machine Main Components

The size of the chamber is defined by the amount of pallets you want to cool at the same time, and their individual dimensions.

The size of the chamber will decide the number of vacuum pumps to be used. The (2-stage) Chinese DLT pumps excel in their sample but effective construction, and are very efficient in usage.

The evaporator (water catcher, special 'ColdMax ' technology, patent pending!) inside the vacuum chamber condenses the water vapour, and ensures only dry air leaves the vacuum chamber towards the pumps.

Outside the chamber, the cold medium (R407c, R407f, R134a) is cooled down by a refrigeration system. The compressor needed for this heat exchange process is supplied by bitzer (Germany) or by Hanbell (Tainwan).

Vacuum Cooling Machine Condenser System Type

Type | Features |

Air condenser | The simplest construction, suitable for small system.Easy to integrate |

Water condenser | Low cost, efficient and easy to install. Perfect for most districts climates |

Evaporative condenser | Optional system for dry climates, or if water availability is limited |

The Door Tpype of Vacuum Cooling Machine

Type | Features |

Standard swing door | The simplest construction, manual operation. The ramp for this system is relatively long, and is mounted inside the cooling chamber |

Horizontal sliding door | This eletrical driven door is optimal if the cooling skid is placed besides the vaccum chamber (one pallet modle and more than 6 pallets systems) |

Upward lift door | Suggested solution for all systems from 2-6 pallets. Easy installation , easy ramp construction. |

Standard Models & Basic Specs of Vacuum Cooling Machine

Our standard range consists of models for 1 up to 10 pallets, and produce weight ranging from 250 to 4,000 kg. The number of pallets defines the chamber dimensions, and the number of vacuum pumps needed to create the vacuum.

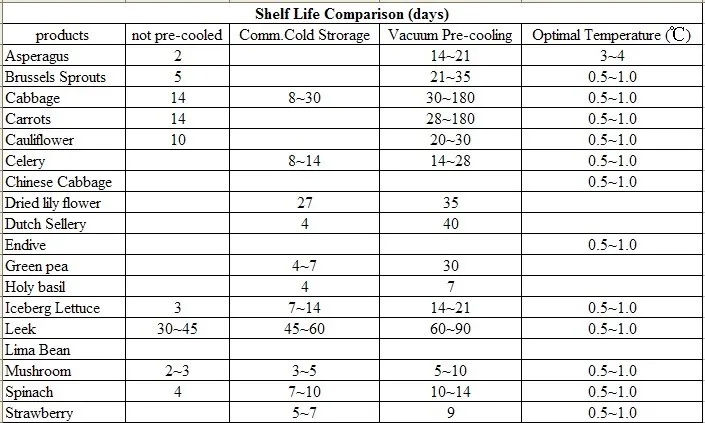

Vacuum Cooling Machine Application Fields

We Recommend

New Arrivals

New products from manufacturers at wholesale prices