high performance cost ratio air compressor

- Category: >>>

- Supplier: Hangzhou Ourui Air Separation Equipment Co. Ltd.Hangzhou Ltd.

Share on (1600359636455):

Product Overview

Description

The main advantages

1. High reliability, fewer parts, no wearing parts, so it is reliable operation, long life, the general screw machine main head design life of 30 years.

2. Convenient operation and maintenance, high degree of automation, operators do not need to go through a long period of professional training, to achieve unattended operation.

3. Good power balance, no unbalanced inertia force, the machine can work smoothly at high speed, to achieve no foundation operation.

4. Strong adaptability, with the characteristics of forced gas transmission, volume flow is almost not affected by exhaust pressure, in a wide range of working conditions can maintain high efficiency, in the compressor structure without any change, suitable for a variety of working conditions, so easy to finalize the batch production.

5. Multi-phase mixing, rotor tooth surface actually has a gap, so it can withstand liquid impact, can send liquid gas, dust gas, easy to polymerize gas, etc.

6. Slide valve flow regulation, no need to hit backflow, can effectively reduce energy consumption.

Application:

1. The screw air compressor: it is mainly used for aerodynamic field, used to drive all kinds of pneumatic tools, due to the development of oil and gas separation and purification technology of gas, and is increasingly used in very high demand on air quality of applications, such as food, medicine and industry such as cotton, occupied many original oil-free air compressor of the market.

2. Screw process compressor: used to compress all kinds of gas in the process, such as: carbon dioxide, ethylene, methane, hydrogen, natural gas, torch gas, etc.

We Recommend

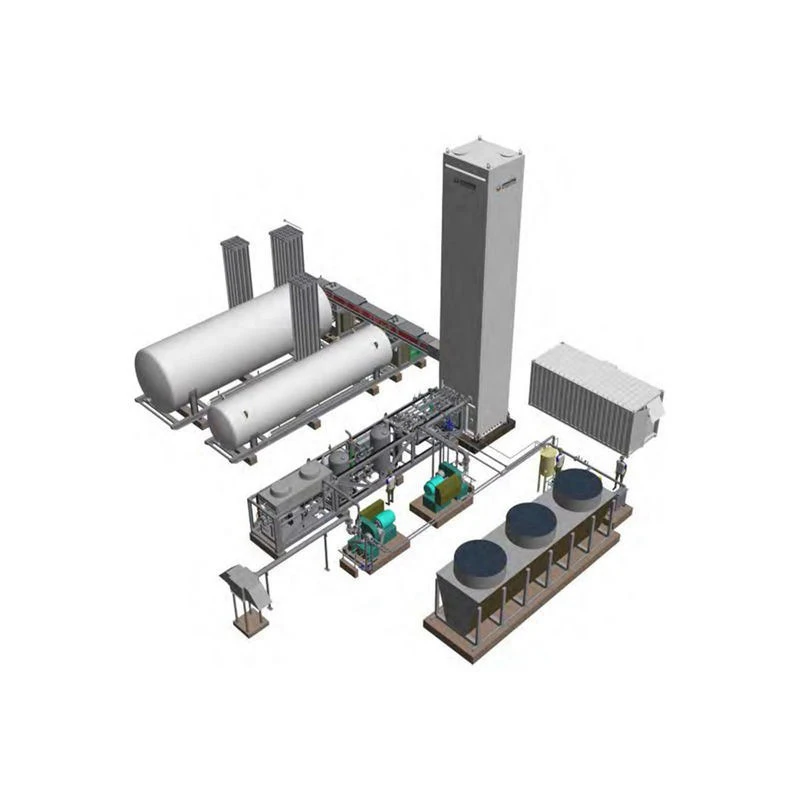

Cryogenic air Separation Unit Gas with Two Columns Oxygen Nitrogen Producing Manufacturers

New Arrivals

New products from manufacturers at wholesale prices