Robotic system Computer Integrated Manufacturing and Handling System Didactic Educational School Laboratory Equipment

- Category: >>>

- Supplier: Jinan Should Shine Didactic Equipment Co. Ltd.

Share on (1600366954240):

Product Overview

Description

Product Description

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

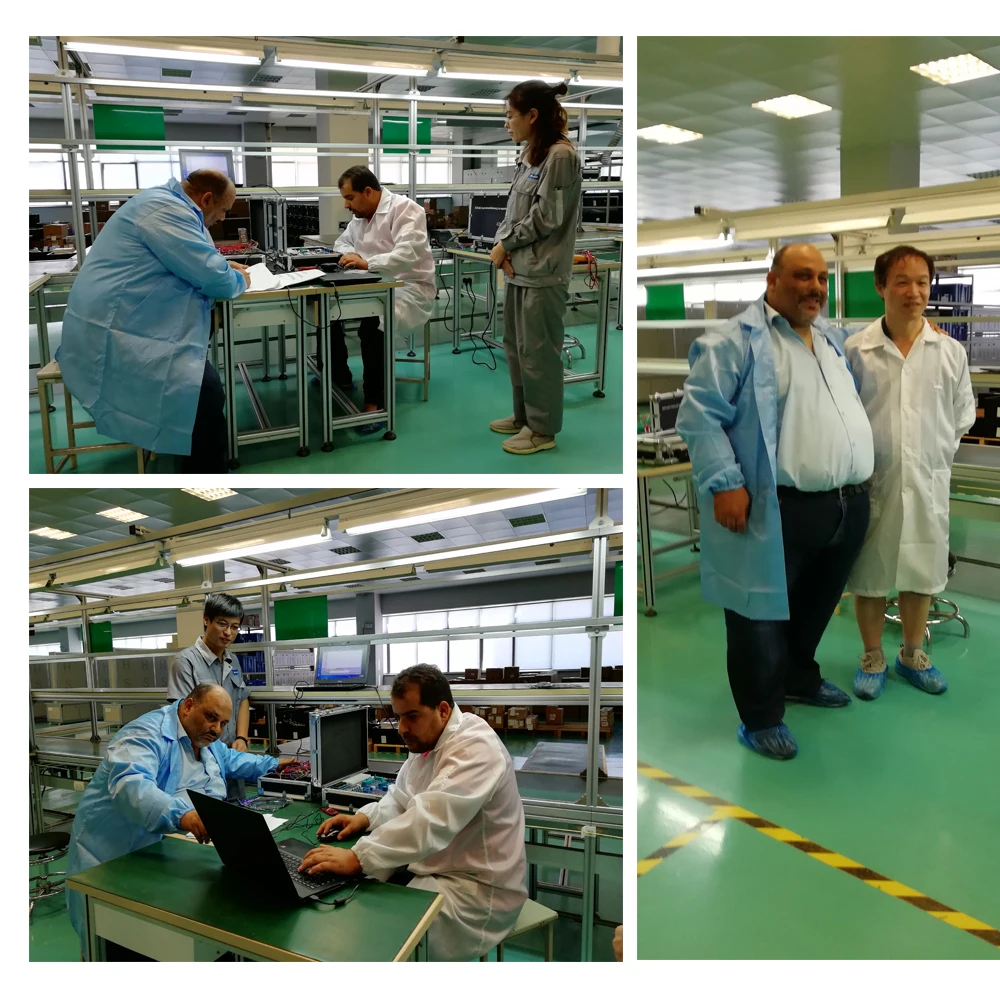

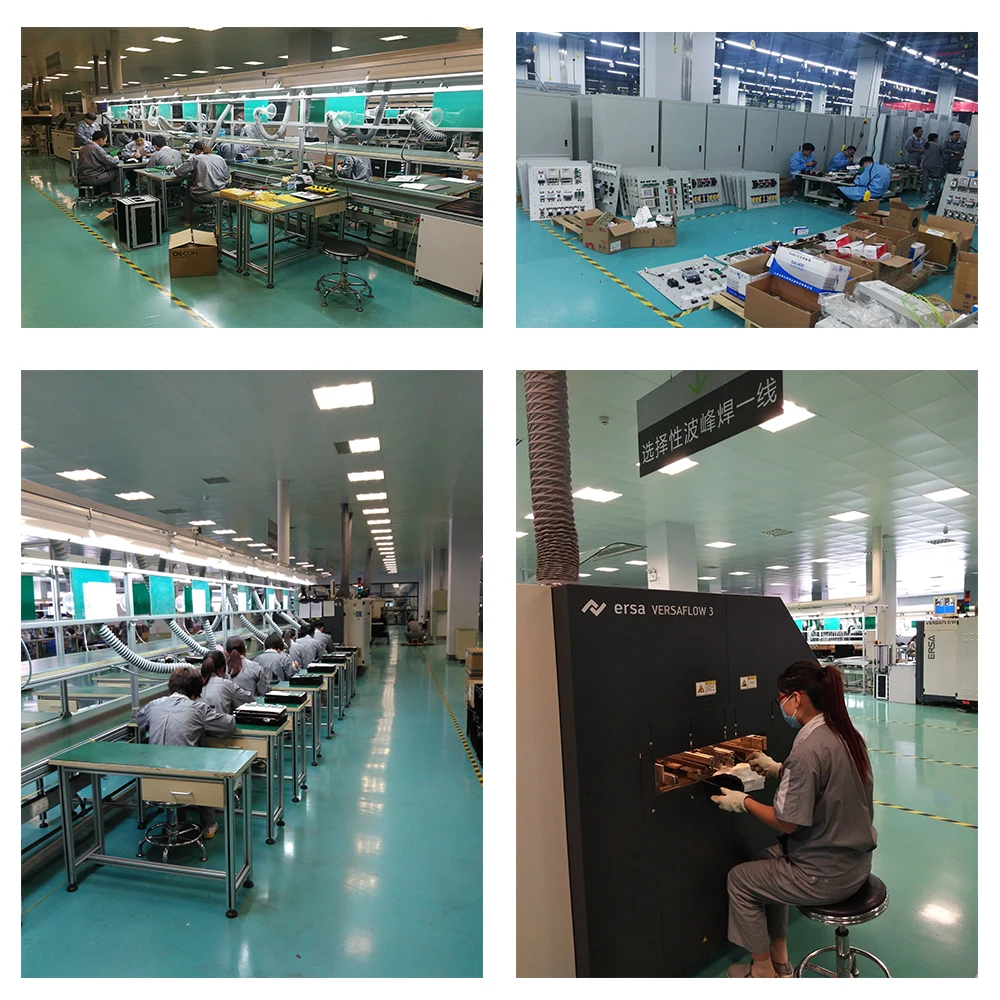

Company Profile

Jinan Should Shine supply educational equipment, didactic equipment, vocational training equipment for university, college, engineer training centers. Jinan Should Shine design, develop, manufacture and supply after sales service for educational equipment for USA, Canada, U.K., Australia, New Zealand, and more than 80 countries in the world, with more than 10 years design, manufacture and export service, with 10 engineer design team, and 10 international sales team, supply professional technical consultant and professional after sales services.

With self owned brand: ShouldShine, JSS, SSEDU, gunt, and passed ISO9001 certificate since 2013. Jinan Should Shine is Alibaba verified supplier, past Intertek on site checking.

Jinan Should Shine has a wide range of products including 8 ranges: electrical training equipment, mechatronics training

equipment, fluid lab equipment, thermal training equipment, refrigeration training equipment, food machine trainer, PCB lab

equipment, mechanical training equipment.

With self owned brand: ShouldShine, JSS, SSEDU, gunt, and passed ISO9001 certificate since 2013. Jinan Should Shine is Alibaba verified supplier, past Intertek on site checking.

Jinan Should Shine has a wide range of products including 8 ranges: electrical training equipment, mechatronics training

equipment, fluid lab equipment, thermal training equipment, refrigeration training equipment, food machine trainer, PCB lab

equipment, mechanical training equipment.

Products Description

Robotic system Computer Integrated Manufacturing and Handling System Didactic Equipment Mechatronics Trainer

demonstration of automated processes in a CIM cell

robot with linear drive as overhead system

CNC milling machine with pneumatic vice

CNC lathe with automatic tool changer, pneumatic chuck and

pneumatic safety guard opening

parts dispenser with gravity feed for spherical material, capacity dependent on diameter of part

parts inspection station, e.g. for checking work piece diameter finished parts store with self-centering pallets and interchangeable part mounts

sequence control of the individual manufacturing steps by PLC and process control software

communication between PLC and PC via Profibus DP

programming software for CNC machines, robot, PLC, linear drive

under Windows XP

required compressed air supply: 8bar

Linear drive with DC servo motor:

-travel: 1.800mm

-repeat accuracy: 0,1mm

-max. velocity: l,4m/s

5-axis robot with AC servomotors:-

-all 5 axes can be moved simultaneously

-2-finger gripper: gripping force programmable

CNClathe:-

-drive power output: 250W

-distance between centres: 200mm

-height of centres: 32mm (support) / 90mm (bed)

-spindle speed: 200...2.500min-l

CNC milling machine and drill:-

-drive power output: 250W

-travel: x=216mm / y=114mm / z=140mm

-spindle speed: 200...2.500min-l

PLC.-

-40 digital / 2 analogue inputs

-38 digital outputs / 1 analogue output

Dimensions:-

LxWxH: 2.400x800xl.920mm Weight: approx. 300kg Required for Operation:- 230V, 50Hz, 1 phase Compressed air connection: 8bar Set consisting of -1 CIM cell -2 PCs

1 set of instructional material

comprehensive trainer for demonstration and exercises in pneumatics, electro-pneumatics and PLCs

2 perforated metal panels for quick component fixing standard industrial pneumatic and electro- pneumatic components various multi-way valves, pressure, shut-off and flow control valves electric limit switch, various proximity switches, solenoid valves

robot with linear drive as overhead system

CNC milling machine with pneumatic vice

CNC lathe with automatic tool changer, pneumatic chuck and

pneumatic safety guard opening

parts dispenser with gravity feed for spherical material, capacity dependent on diameter of part

parts inspection station, e.g. for checking work piece diameter finished parts store with self-centering pallets and interchangeable part mounts

sequence control of the individual manufacturing steps by PLC and process control software

communication between PLC and PC via Profibus DP

programming software for CNC machines, robot, PLC, linear drive

under Windows XP

required compressed air supply: 8bar

Linear drive with DC servo motor:

-travel: 1.800mm

-repeat accuracy: 0,1mm

-max. velocity: l,4m/s

5-axis robot with AC servomotors:-

-all 5 axes can be moved simultaneously

-2-finger gripper: gripping force programmable

CNClathe:-

-drive power output: 250W

-distance between centres: 200mm

-height of centres: 32mm (support) / 90mm (bed)

-spindle speed: 200...2.500min-l

CNC milling machine and drill:-

-drive power output: 250W

-travel: x=216mm / y=114mm / z=140mm

-spindle speed: 200...2.500min-l

PLC.-

-40 digital / 2 analogue inputs

-38 digital outputs / 1 analogue output

Dimensions:-

LxWxH: 2.400x800xl.920mm Weight: approx. 300kg Required for Operation:- 230V, 50Hz, 1 phase Compressed air connection: 8bar Set consisting of -1 CIM cell -2 PCs

1 set of instructional material

comprehensive trainer for demonstration and exercises in pneumatics, electro-pneumatics and PLCs

2 perforated metal panels for quick component fixing standard industrial pneumatic and electro- pneumatic components various multi-way valves, pressure, shut-off and flow control valves electric limit switch, various proximity switches, solenoid valves

We Recommend

New Arrivals

New products from manufacturers at wholesale prices