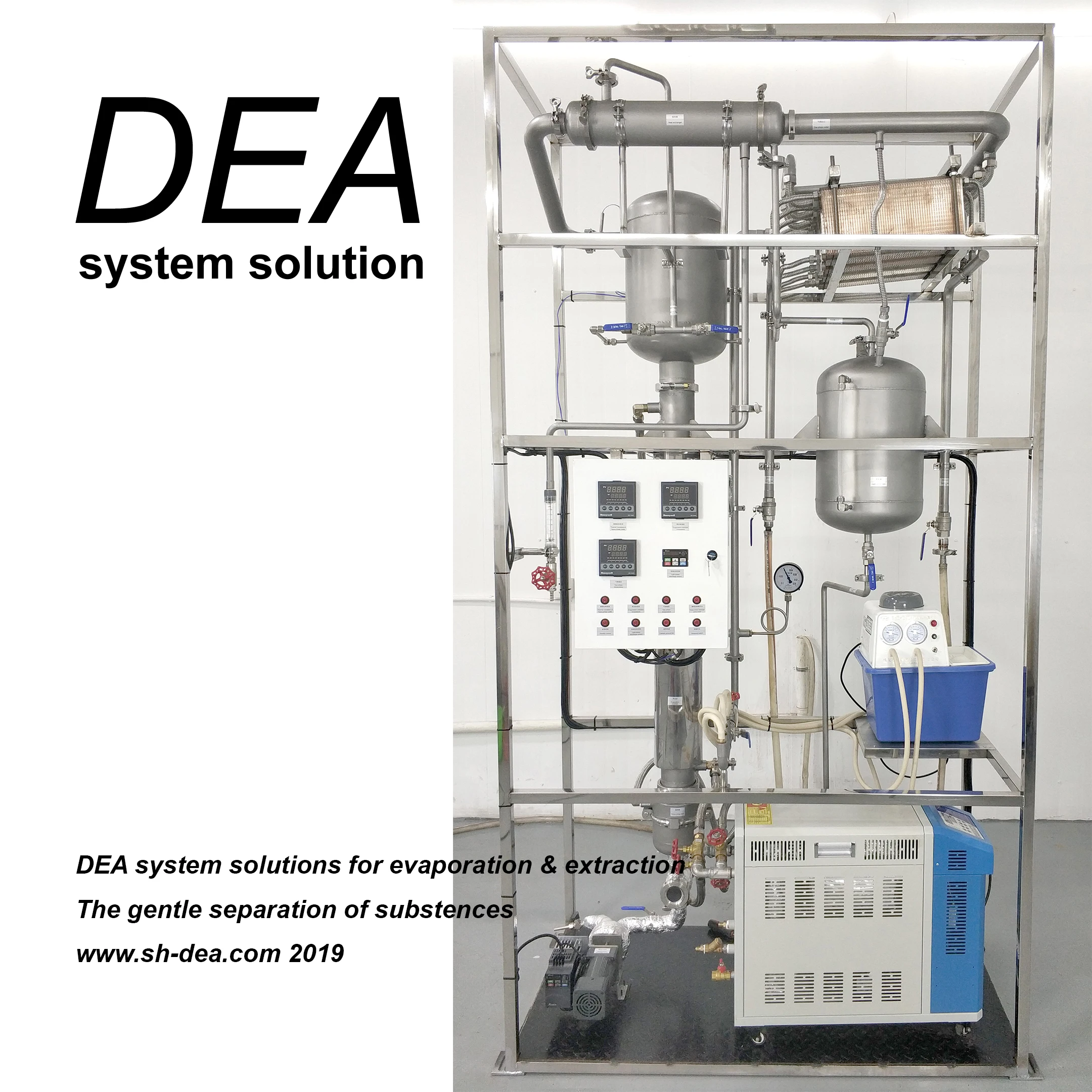

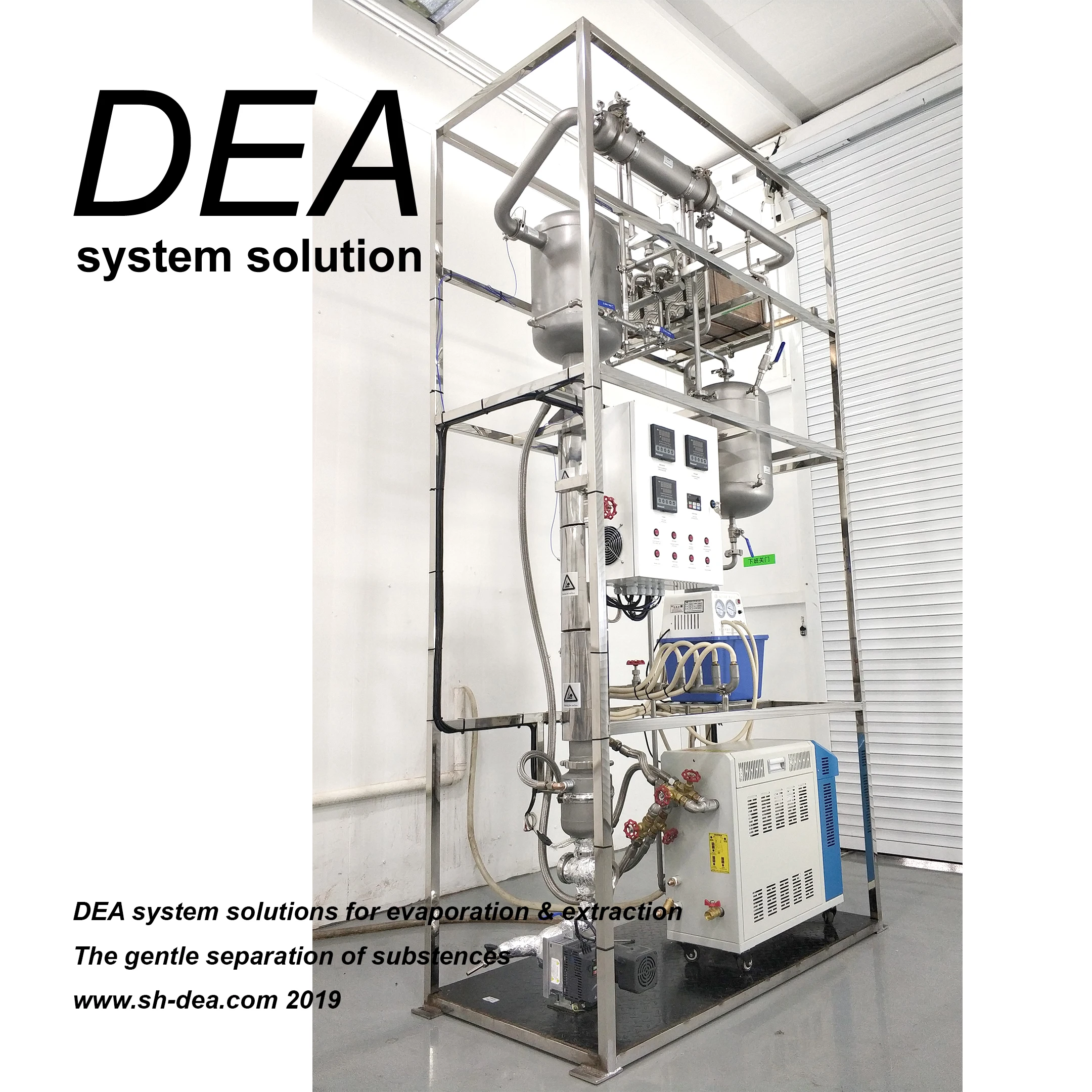

DEA FM 40 Manufacturer Customized Extract Concentrated Evaporator Single Effect Falling Film Evaporation Equipment

- Category: >>>

- Supplier: Shanghai Dea Chemical Equipment Co. Ltd.

Share on (1600389297091):

Product Overview

Description

Product Description

DEA-FM-40 Manufacturer Customized Extract Concentrated Evaporator Single-Effect Falling Film Evaporation Equipment

MODEL | FM-40 | ||||||

MATERIAL | stainless steel 304 | ||||||

TEMPERATURE | Room temp~200 ℃(Electric heating not included) | ||||||

DIAMETER | 100 (mm) | ||||||

HEAT EXCHANGER HTA | 1(m2) | ||||||

FEED AMOUNT | 40 (L/h) solvent | ||||||

VACUITY | 50mbar(depend on the nature of material and vacuum pump)(vacuum pump not included) | ||||||

FLOOR AREA | length*width*height=1200*800*2500 (mm)(without pump) | ||||||

POWER | 12KW (without vacuum pump) | ||||||

VOLTAGE | 380V (we offer voltage transformer) | ||||||

FFE Introduction

——Design

A vertical shell-and-tube heat exchanger, with a laterally or concentrically arranged centrifugal separator.

——Operation

The concentrated liquid is supplied to the top of the heating tubes and distributed in a way as to flow down the inside of the tube walls as a thin film. The liquid film starts to boil due to the external heating of the heating tubes and is partially

evaporated as a result. The downward flow, caused initially by gravity, is enhanced by the parallel, downward flow of the vapour formed. Residual film liquid and vapour is separated in the lower part of the calandria and in the downstream centrifugal droplet separator. It is essential that the entire film heating surface, especially in the lower regions, be wetted with liquid evenly and sufficiently. Otherwise, dry spots will result that will lead to incrustation and the build-up of deposits.

For evenly distribution, it is important that a suitable distribution system is selected for the head of the falling film

evaporator. Wetting rates are increased by using longer heating tubes, dividing the falling film evaporator into several

compartments or by recirculating the product.

——Particular features

Better product quality – due to gentle evaporation, mostly in vacuum, and extremely short residence times in the falling film evaporator.

High energy efficiency – due to more tubes or heating by heat pump compressor, based on the lowest theoretical temperature difference.

Flexible operation – quick start-up and easy switchover from operation to cleaning.

——Fields of application

Relatively small floor space requirement.

Particularly suited for temperature-sensitive products.

For liquids which contain small quantities of solids and low moderate tendency to form incrustations.

A vertical shell-and-tube heat exchanger, with a laterally or concentrically arranged centrifugal separator.

——Operation

The concentrated liquid is supplied to the top of the heating tubes and distributed in a way as to flow down the inside of the tube walls as a thin film. The liquid film starts to boil due to the external heating of the heating tubes and is partially

evaporated as a result. The downward flow, caused initially by gravity, is enhanced by the parallel, downward flow of the vapour formed. Residual film liquid and vapour is separated in the lower part of the calandria and in the downstream centrifugal droplet separator. It is essential that the entire film heating surface, especially in the lower regions, be wetted with liquid evenly and sufficiently. Otherwise, dry spots will result that will lead to incrustation and the build-up of deposits.

For evenly distribution, it is important that a suitable distribution system is selected for the head of the falling film

evaporator. Wetting rates are increased by using longer heating tubes, dividing the falling film evaporator into several

compartments or by recirculating the product.

——Particular features

Better product quality – due to gentle evaporation, mostly in vacuum, and extremely short residence times in the falling film evaporator.

High energy efficiency – due to more tubes or heating by heat pump compressor, based on the lowest theoretical temperature difference.

Flexible operation – quick start-up and easy switchover from operation to cleaning.

——Fields of application

Relatively small floor space requirement.

Particularly suited for temperature-sensitive products.

For liquids which contain small quantities of solids and low moderate tendency to form incrustations.

Related Products

Cooperation Case

Packing&Shipping

Our equipment has been assembled and tested prior to shipping finished, so it is a whole package, which can be used directly afterunpacked. Please measure the size of the door in order to handle the equipment to the right position. For self-assembly, please inform in advance.

Company Introduction

Shanghai Dea chemical equipment Co.,Ltd

——We devote to design and develop the equipment of chemical separation and abstraction.

——We came from East China University of Science and Technology, which we long-term cooperated with later. And now, we serve for many famous universities, such as Tsinghua University , Sun Yat-sen University , etc.

——We provide equipment of distillation and extraction for the technicians in the area of chemical , medicine and food industry.

——We own senior engineers who have rich experience in chemical engineering.

——Our products can be used in lab-scale, pilot-scale experiments and small-scale production.

——The experimental results are more authentic by using our products thanks to the continuous operation during the course of the experiments or pilot-scale experiments.

——We repaire imputed equipments out-of-warranty for UIC,POPE,BUCHI in the past few years, which made us accumulating rich experience.

——We devote to design and develop the equipment of chemical separation and abstraction.

——We came from East China University of Science and Technology, which we long-term cooperated with later. And now, we serve for many famous universities, such as Tsinghua University , Sun Yat-sen University , etc.

——We provide equipment of distillation and extraction for the technicians in the area of chemical , medicine and food industry.

——We own senior engineers who have rich experience in chemical engineering.

——Our products can be used in lab-scale, pilot-scale experiments and small-scale production.

——The experimental results are more authentic by using our products thanks to the continuous operation during the course of the experiments or pilot-scale experiments.

——We repaire imputed equipments out-of-warranty for UIC,POPE,BUCHI in the past few years, which made us accumulating rich experience.

www.sh-dea.com

www.sh-dea.com/indexEG.htm

We Recommend

New Arrivals

New products from manufacturers at wholesale prices