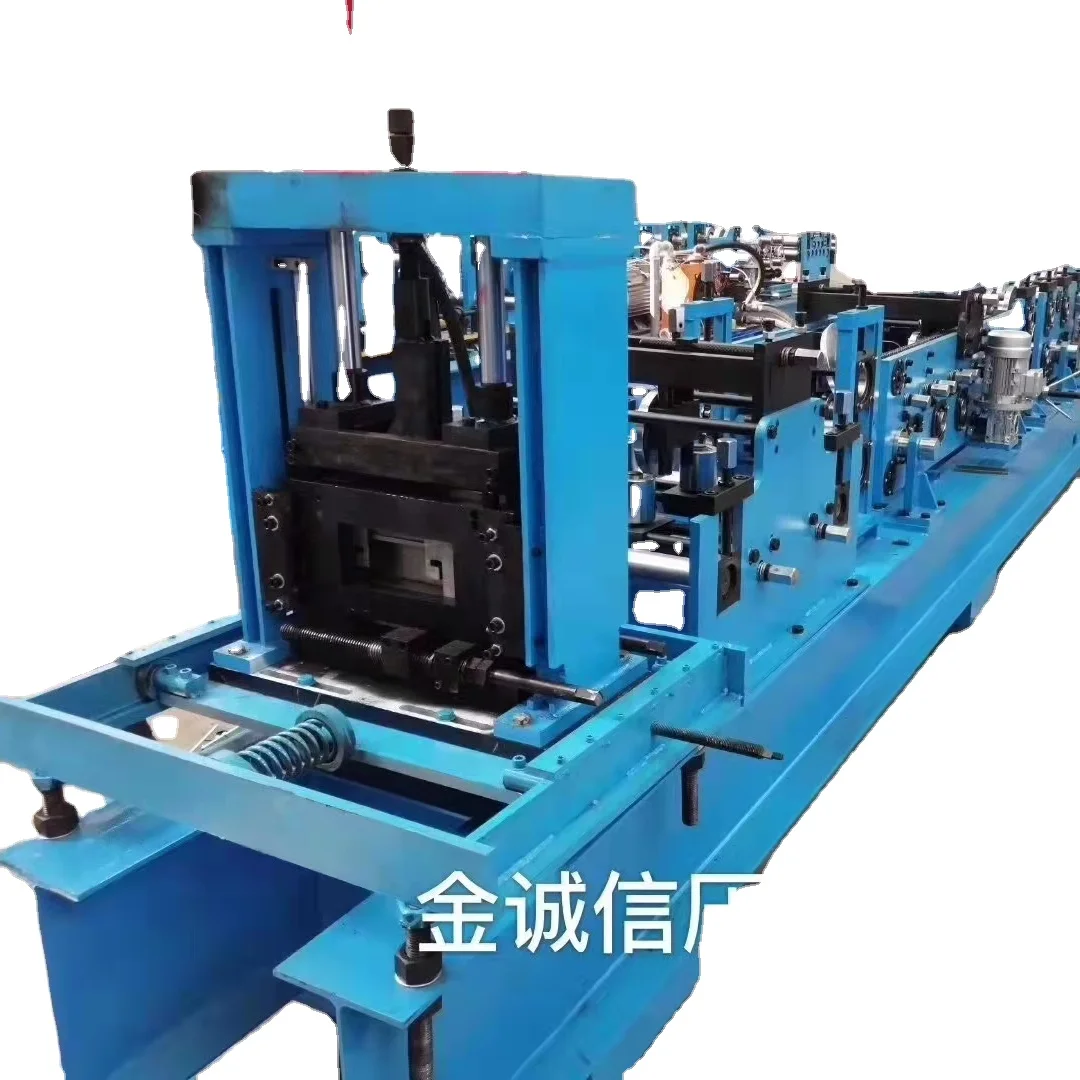

C U Channel Steel Material fence roll forming machine

- Category: >>>

- Supplier: Taizhou Huangyan Harson Plastic Co. Ltd.

Share on (1600403418149):

Product Overview

Description

| Machine |

1. Forming main machine 1. Feeding: guide shaft+guide wheel

2. Leveling: upper two, lower three+two leading. Material: 45# processing technology: rough turning+high frequency heat treatment HRC50-55+ cylindrical fine grinding+surface polishing and hard chrome plating

3. Main molding: 14 components, equipped with 3 groups of mold changing modules, and the size can be adjusted by electric buttons.

4. Pressing ribs: straight ribs, manually adjust the width of straight ribs.

5. Alignment: Align the second and third axes up and down.

6. Punching: Punching single hole+punching double holes at the bottom of profile, with round holes φ 14 mm and φ 16 mm and long holes 28×16mm or 28×14mm as an alternative. The standard single hole and double hole of the equipment are 28×16mm.

8. Cutting: the endless cutting system after molding, cutting without changing the tool, manually changing the mold. Knife material: Cr12

II. Control system

1. Main control cabinet: 1 (aviation plug)

2. Type changing method: (electric) type changing, (four type changing motors: 0.55KW*4)

3. Change-type distribution box: 1 (installed in the middle of the rack)

4. External controller: 1 (which is convenient for inching forward and backward control in the production process and debugging process)

5. Origin of main accessories: PLC (Panasonic), touch screen (Weilun), electrical components (Chint), length encoder (Omron, Japan) Voltage: three-phase 220/60hz. System 1. Hydraulic motor: external five-star piston connecting rod (Ningbo Hanzhu) 2. Hydraulic station: hydraulic station power 15KW oil tank volume 500 liters 3. Origin of main parts: solenoid valve Zhejiang Yongxin IV. Discharging machine 1. Load: 5 tons 2. Tightening method: the center of hand-operated four-link rod is tightened outwards 3. Braking: double clamping of main shaft 6. Parameter 1. Roll material: GCr15 Wuxi processing technology: forging tempering+roughing+quenching HRC58-60+ CNC finishing, polishing and hard chromium plating after finishing 2. Spindle: material: 45# processing technology: quenching and tempering HB210-230+ roughing+cylindrical grinding+hard chromium plating on polished surface. 3. Sliding sleeve material: 45# processing technology: quenching and tempering treatment HB210-230+ finishing turning+hard chromium plating on the polished surface.

VII. Production product parameters 1. Production product specifications: 01.C width (60-200mm) can be changed at will;

02. Arbitrary change between waist height (35-80mm);

03 Small side (10-20mm);

04 Adjustable plate thickness t(1.2-2.0mm)

2. Discharge speed: high speed 20m/min (according to the number of holes punched)

3. Material application: Q195, Q235 hot rolled strip steel or hot rolled galvanized strip steel (1.2-2.0mm) 8. Main machine parameters: 9.5m long × 1.2m wide × 1.7m high. Main engine weight: 7.5 tons. IX. Attached accessories and conditions XI.

With more than 100 experienced worker and designers, Taizhou Harson Plastic Co.Ltd in one of the competitive manufactures engaging in various pet products such as pet toys,pet cleaning & grooming products, pet bowls & feeders.pet carrier,pet beds & cages.pet collars & leashes and so on. Our slogan is "Care what pets love, care our clients care".

With more than 100 experienced worker and designers, Taizhou Harson Plastic Co.Ltd in one of the competitive manufactures engaging in various pet products such as pet toys,pet cleaning & grooming products, pet bowls & feeders.pet carrier,pet beds & cages.pet collars & leashes and so on. Our slogan is "Care what pets love, care our clients care".

Insisting on supplying high qualified products and good services, our products are welcomed in America, Europe, Russia and many other countries and regions.

We regards “high quality, competitive price, on-time delivery, and fast and effective communications” as our tenet.

We are looking forward to more cooperation with you.

Why Choose US?

Why Choose US?

1.High qualified products and Factory's direct sale price

2.Your enquiry would be replied in 12 hours

3.Well-trained & experienced sales can reply your inquiries in English.

4.The order will be produced exactly according to order details and proofed samples. Our QC will submit inspection report before shipment.

5.A variety of packaging for your choice

6.Superior after-sales services to you

7.Your business relationship with us will be confidential to any third part

We Recommend

New Arrivals

New products from manufacturers at wholesale prices