Manufacture CNC high Precision engine stator rotor grinder tool Metal surface grinding machine

- Category: >>>

- Supplier: Yuhuan Cnc Machine Tool Co. Ltd.

Share on (1600427265093):

Product Overview

Description

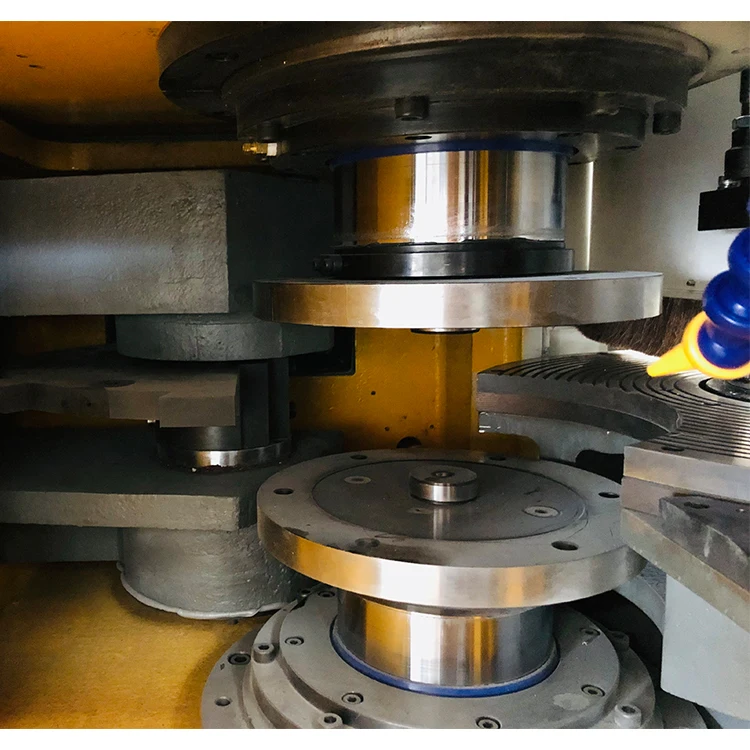

Manufacture CNC high Precision engine stator rotor grinder tool Metal surface grinding machine

1. This machine tool is a high-efficiency machine tool, suitable for batch processing of parts.

2. It is mainly used to grind the surface of parts. It uses resin grinding wheels, CBN grinding wheels, diamond grinding wheels, and diamond grinding pads to perform high-efficiency and precise double-sided grinding of metal and non-metallic hard and brittle materials such as steel, copper, cemented carbide, glass, and ceramics processing.

3. It can be widely used in hydraulic and pneumatic components, hydraulic motor components, automotive fuel pump components, refrigeration compressor components, oil pump nozzle components, engine components, high-precision bearing rollers and rings, seals, piston rings, measuring tools, Double-sided precision grinding of molds, instruments, carbide blades, ceramic valve cores, magnetic materials and other products.

Technical Feature

1. The Feeding of upper and lower grinding head is driven by servo motor with transmission mechanism and large diameter double-nut ball screw.

2. The feed of the upper and lower grinding heads is controlled by the Siemens 808D system numerical control system, and the backlash between the feed screw and the nut is compensated by the numerical control system

3. The spindle bearing of the grinding head adopts the German FAG brand.

4. The machine tool has the functions of automatic dressing and grinding wheel consumption compensation; the machine's grinding position, dressing position, dressing amount and times, compensation amount, etc. can be set in the CNC system.

5. The feeding mechanism adopts the dual-station planetary feeding method, which is convenient for loading and unloading.

6. The feeding mechanism adopts three independent servo motor drive structure to realize the planetary movement of rotation and revolution

7. The feeding panel adopts Cr12 material to be quenched as a whole to ensure Abrasion resistance

8. Loading and unloading institutions are customized according to customer needs

9. The machine tool adopts a centralized automatic lubrication system to automatically lubricate the main lubrication parts of the machine tool with a liquid level alarm.

10. The machine tool is equipped with a cooling filter system, which can perform multi-stage filtration and cooling of the circulating grinding fluid.

Specification

Model | YHMM300A |

Workpiece Range | 100MM(diagonal) |

Workpiece Thickness | 0.6-30mm (C Type Grinding) |

Wheel Head Speed | 500-1500/rmp (stepless work speed regulation ) |

Diagonal of Grinding Wheel | 305x125x60mm |

Motor power of upper and lower spindle | 2×7.5KW |

Lower spindle servo motor | 1.5KW |

Power of Workpiece rotation motor | 2×0.75KW |

Power of Workpiece feeding revolution motor | 0.75KW |

minimum feed of Spindle setting | 0.001mm |

Feeding Revolution | 1.5-30R/M |

Feeding Rotation | 6-120 R/M (stepless work speed regulation ) |

Control System | Siemens 808D |

The whole Size(L*W*H) | 2030mmX1980mmX2560mm |

Our R&D team has about over 50 engineers, occupied 20% of total staffs. Includes 19 SenierMechanical engineers( 4with doctor’s degree,8 with master’s degree),7 Senierelectrical engineers,5 CNC soft engineers

- The workshop and office area covers 20K Sqmeters.

- With over 270 staffs, including over 50 R&D technical engineers.

- Main products output more than 1000 sets per year.

1.Moisture-proof packaging+Wooden Box.

2.Special packing requirements available.

Our products have been in great demand by more than twenty provinces including Taiwan all around China, and Vietnam, Portugal, Russia, Kenya, Brazil and other countries. We have obtained high prestige from our customers for the high quality products, satisfactory after-sales services and competitive price.

Our R & D team establish a long - term partnership with National University of Defense Technology , Dalian University of Technology , Hunan University , Central South University , and other renowned institutions . Yuhuan is also research base for Hunan University’s doctoral student,get 5—9 patents per year .

- has got 36 related patents

- A certificate of international standard products in 2005

- has passed ISO9001 : 2000 international quality system certification, has estabished corporate product standards

Our products are widely used in Automotive/3C IT Electronic/Military/ Aerospace/ Shipbuilding/Bearings/seals/ Household Appliances/ And other key areas of National Economy.

3. We will offer free the training for machine’s management /operation/maintenance to user’s related people.

Please feel free to contact us,we will reply within 24h!

We want to know:

How much the laser power you need?

What materials do you need to process?

The Cutting size and thickness?

We Recommend

New Arrivals

New products from manufacturers at wholesale prices