Fixed thickness Wide Belt Sanding Machine Drum Sander from other woodworking machinery

- Category: >>>

- Supplier: Qingdao Zhongding Machinery Co. Ltd.

Share on (1600427582448):

Product Overview

Description

Heavy Wide Belt Sanding Machine For Wood

Ensure smooth surface, Auto control speed, Siemens Schneider electric appliance, Taiwan sanding paper.

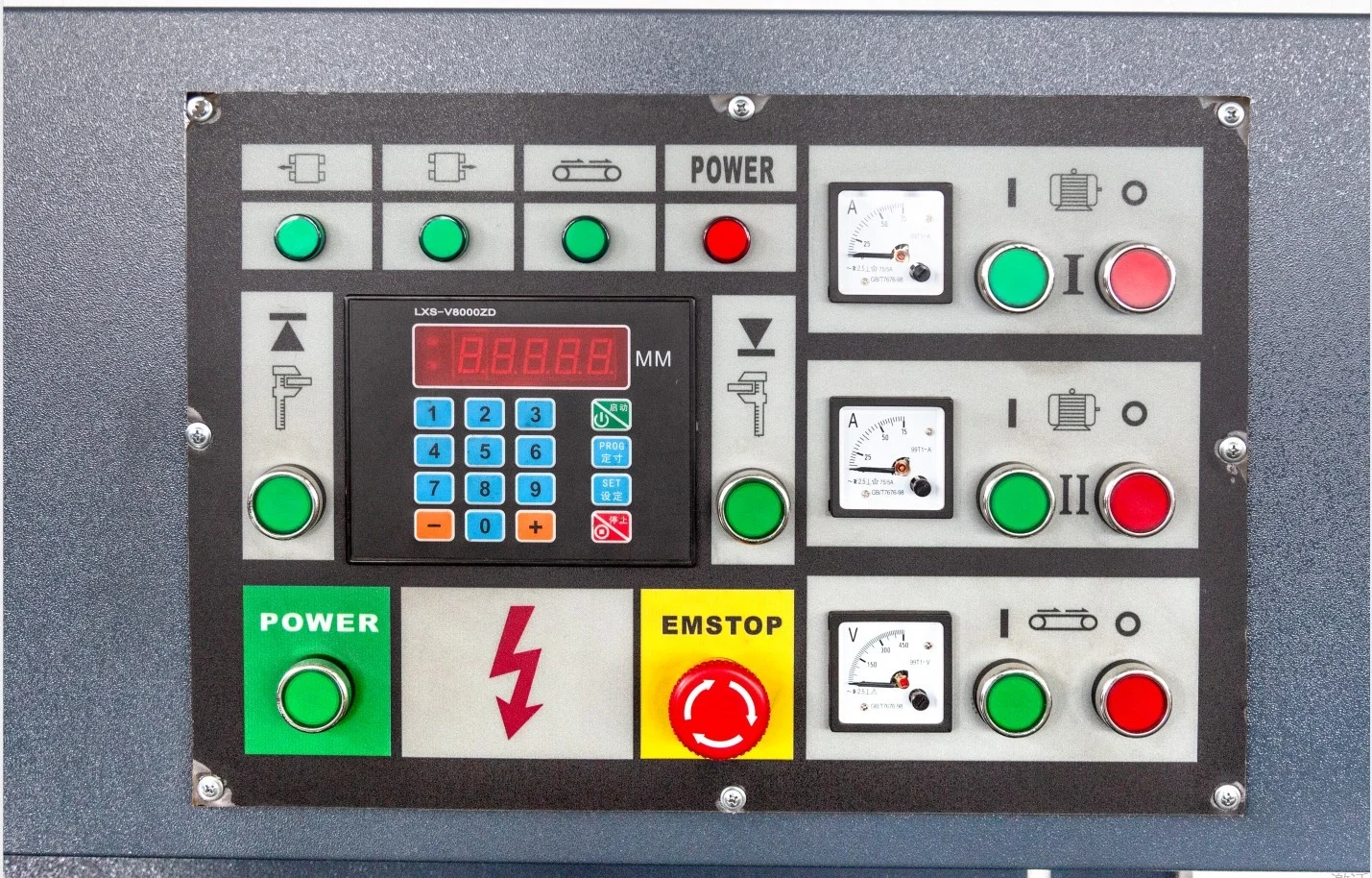

Safety protection, Heavy-duty frame, Easy replaced sanding belt, Easy operation with control panel, 2 years warranty.

——— Technical Parameter

| Working width | 450,630,1000,1300,1600mm | First motor | 5.5, 11, 22, 37, 45kw |

| Min.Working length | 500mm | Second motor | 5.5, 7.5, 15, 22, 30kw |

| Working thickness | 3-110mm | Third motor | 11, 22kw |

| Feeding speed | 6-30m/min | Feeding motor | 0.75, 1.5, 4.5kw |

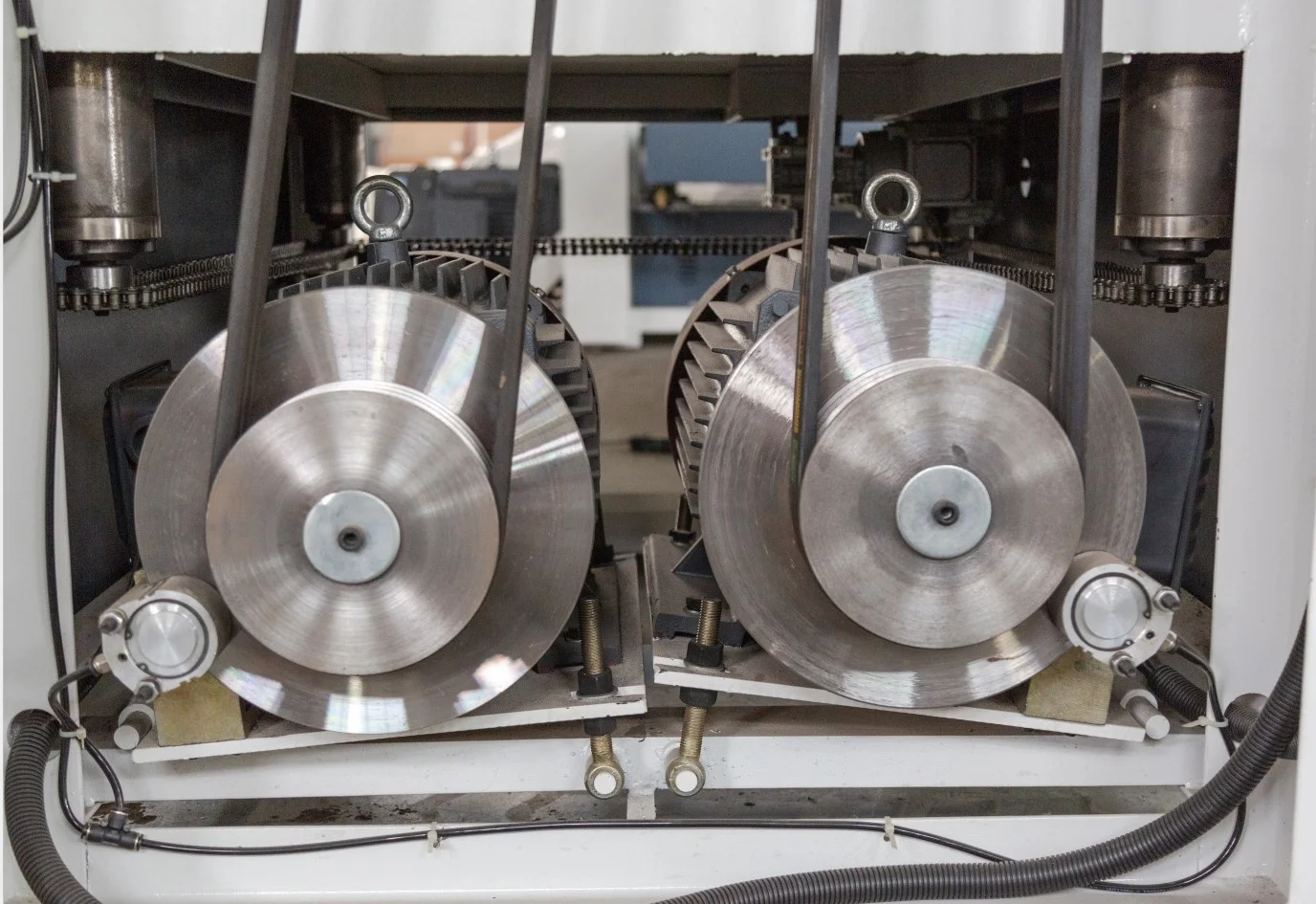

| First roller | 190, 240mm | Lifting motor | 0.37, 0.55kw |

| Second roller | 190, 240mm | Working air | 0.6Mpa |

| Third roller | 210mm | Volume of dust | 8000, 9600, 14000m³/h |

| Abrasive belt size | 470*1930, 650*1930, 1020*2020, 1320*2220mm | ||

| Overall dimensions | 1800*950*2000, 2700*2100*2100, 3000*2400*2100mm | ||

| Weight | 1100, 2200, 3200, 5300, 6500kg | ||

(1) It is suitable for calibrating and fine sanding laminate lumber, composite board, particle board, solid wood, panel furniture, bamboo floor, wood door and etc. It is one of the necessary equipment for integrated wood and furniture manufacturing.

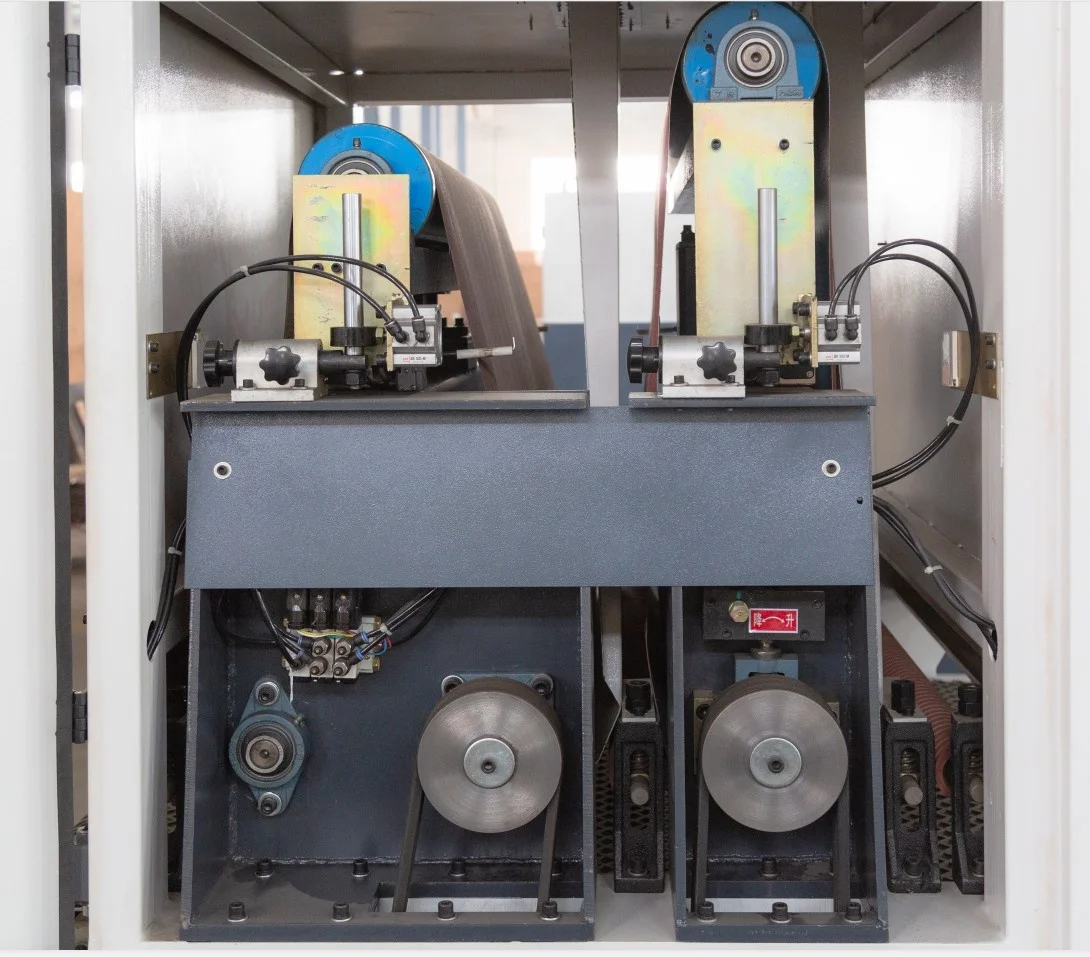

(2) R-RP model: The first roller is steel roller; the second unit is 85°rubber roller with air sanding pad. RP-P model: The first unit is rubber roller with sanding pad; the second unit is air sanding pad. Steel roller is for calibration sanding and rubber roller is for fine polishing.

(3) The pressing roller protects device to keep the board on the feeding table, which keep the operators safe.

——— Functions show

We Recommend

New Arrivals

New products from manufacturers at wholesale prices