Product Overview

Description

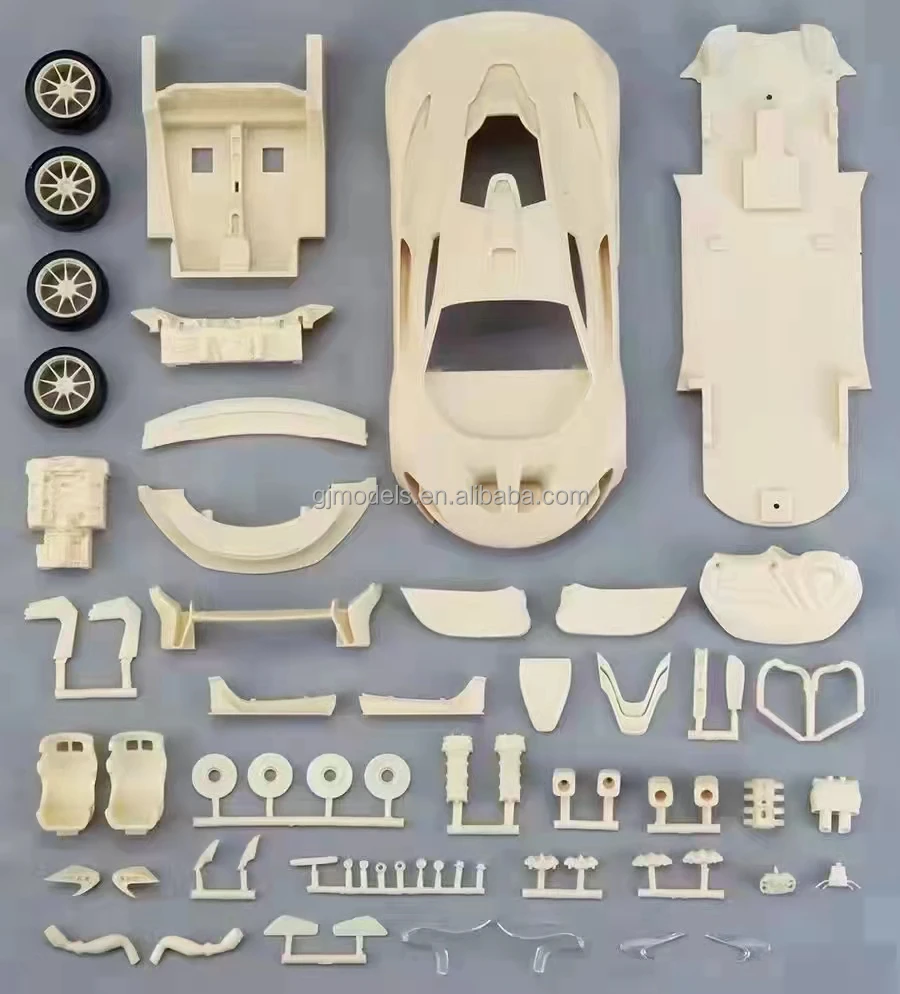

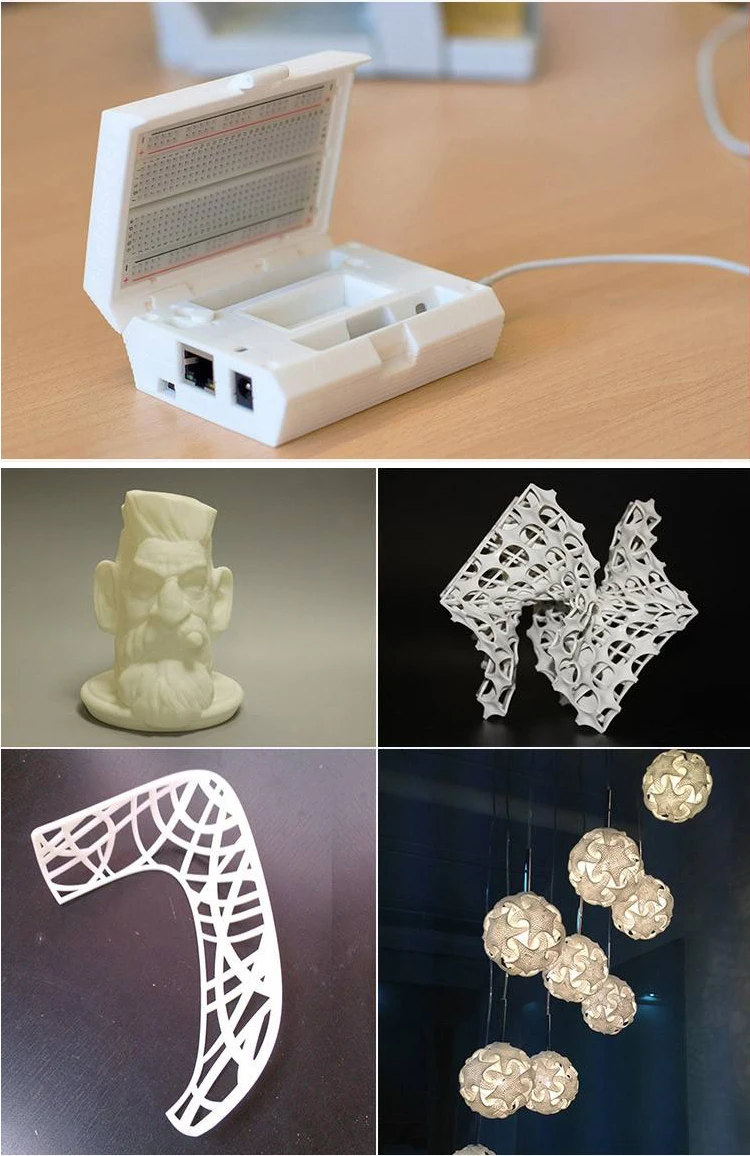

Custom Low Volume Manufacturing Prototype SLA/SLS ABS 3D Printing, Electronic Enclosure Prototype Plastic/Metal Cnc Machining

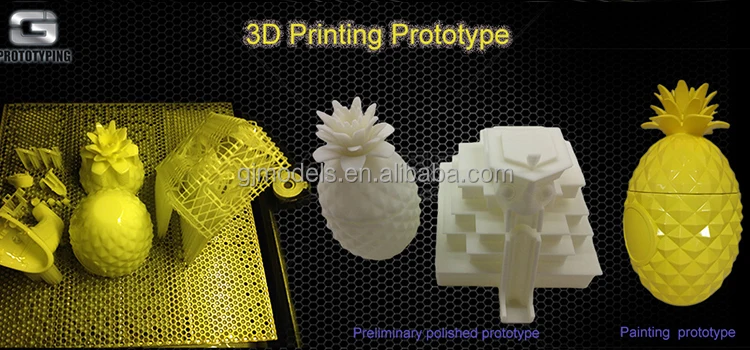

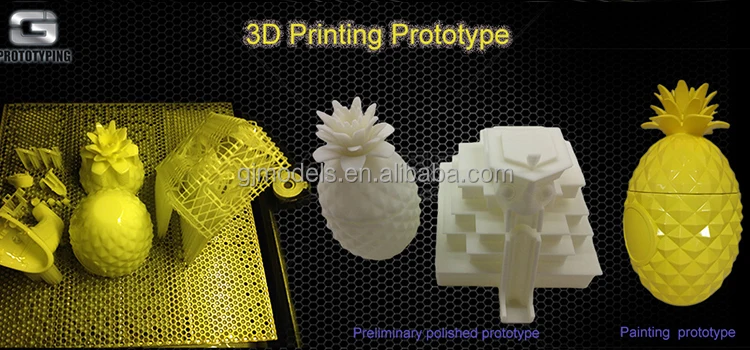

What‘s 3D printing ?

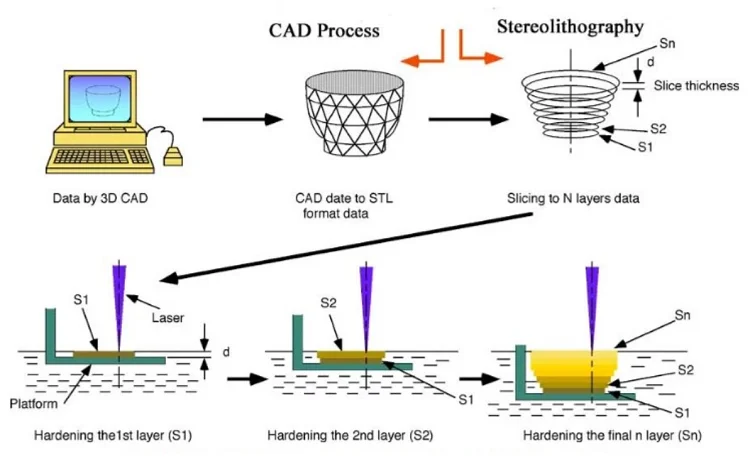

Stereolithography – more commonly referred to as SLA 3D printing – is one of the most popular and widespread techniques in the world of additive manufacturing. It works by using a high-powered laser to harden liquid resin that is contained in a reservoir to create the desired 3D shape. In a nutshell, this process converts photosensitive liquid into 3D solid plastics in a layer by-layer fashion using a low power laser and photopolymerization.

Every standard SLA 3D printer is generally composed of four primary sections:

* A tank filled with the liquid photopolymer: The liquid resin is usually a clear and liquid plastic.

* A perforated platform immersed in a tank: The platform is lowered into the tank and can move up and down according to the printing process.

* A high-powered, ultraviolet laser.

* A computer interface, which manages both the platform and the laser movements.

SLA 3D Printing Advantages:

* SLA is one of the most precise 3D printing techniques on the market.

* Prototypes can be created with extremely high quality, with finely detailed features (thin walls, sharp corners, etc…) and complex geometrical shapes. Layer thicknesses can be made as low as 25 μm, with minimum feature sizes between 50 and 250 μm.

* SLA provides the tightest dimensional tolerances of any rapid prototyping or additive manufacturing technology: +/- 0.005″ (0.127 mm) for the first inch, and an additional 0.002″ for each additional inch.

* Print surfaces are smooth.

* Build volumes can be as high as 2700*900*800mm without sacrificing precision.

SLA technical principle

SLA is a mechanical technology, laser, photochemical, software, the crystallization of control technology. Through software for parts 3D model is stratified, controlled by computer to laser scanning is based on data layer liquid trough of photosensitive resin curing, until the physical prototype.

A correct choice of more than a hundred times the effort.

Appliction Cases:

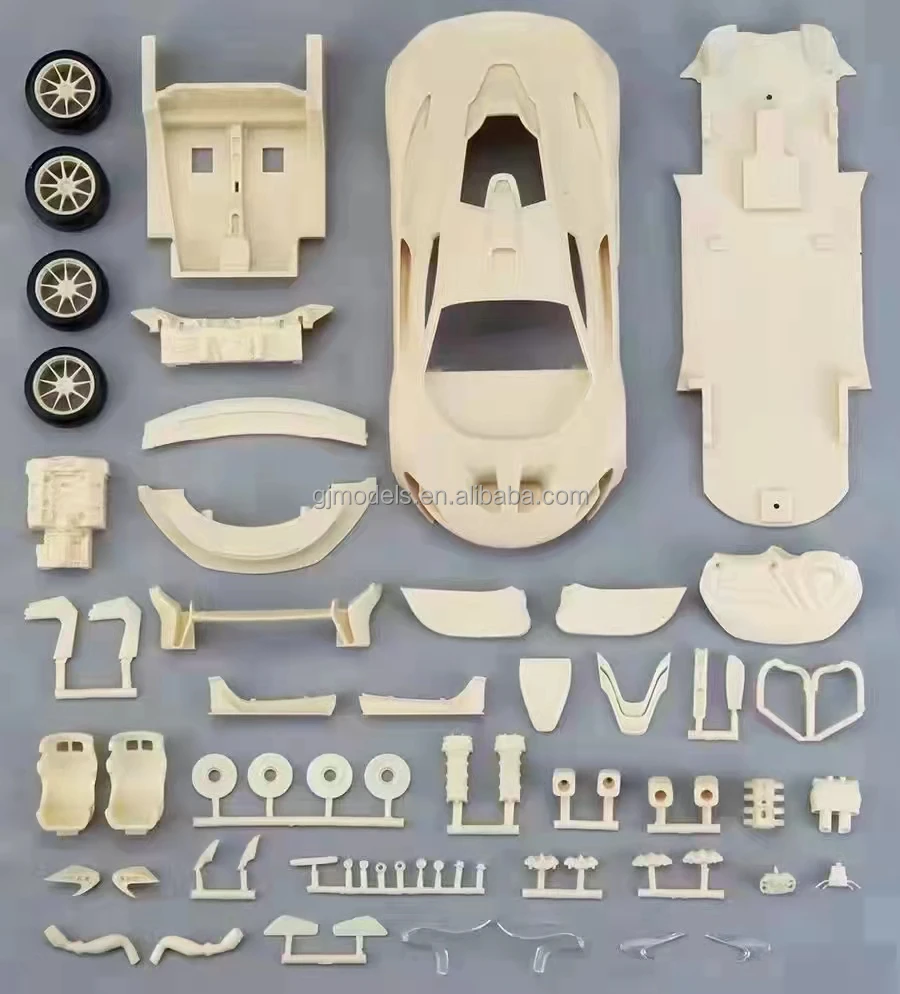

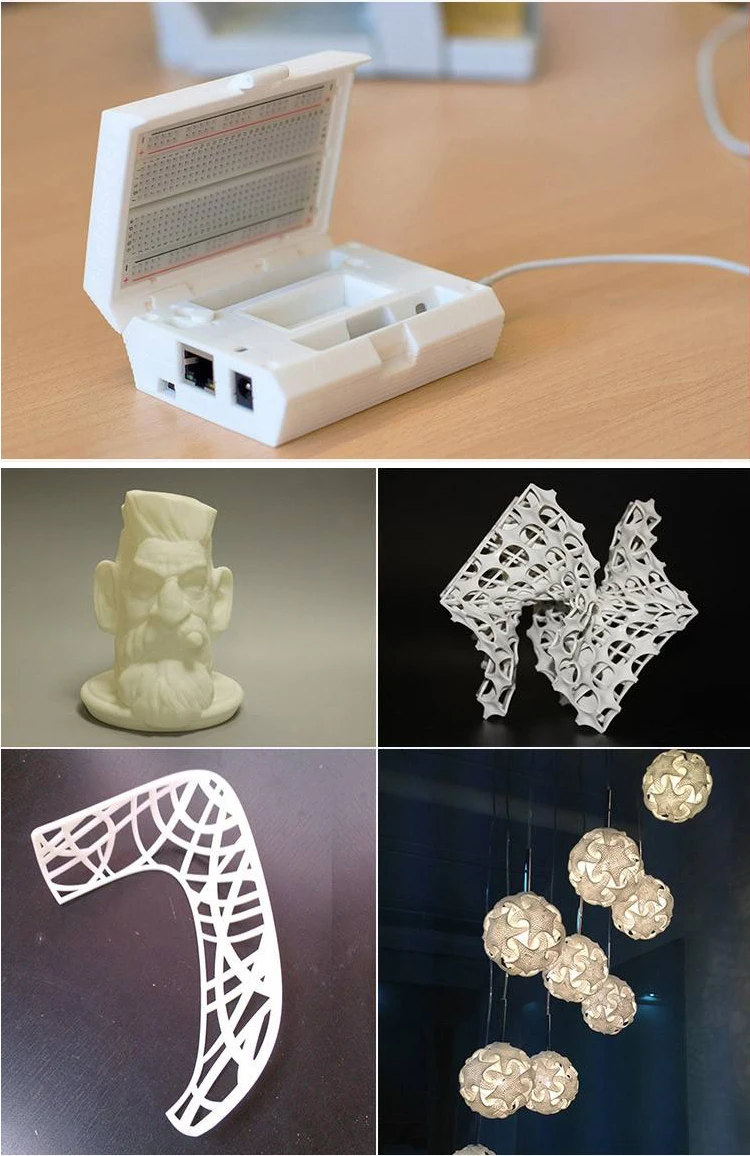

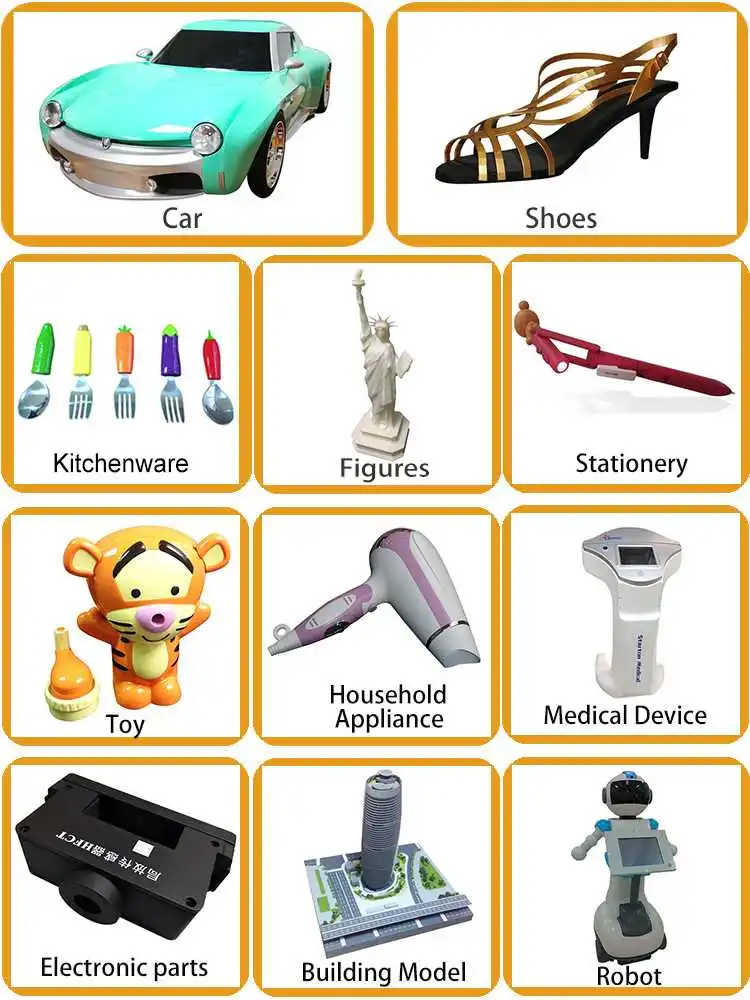

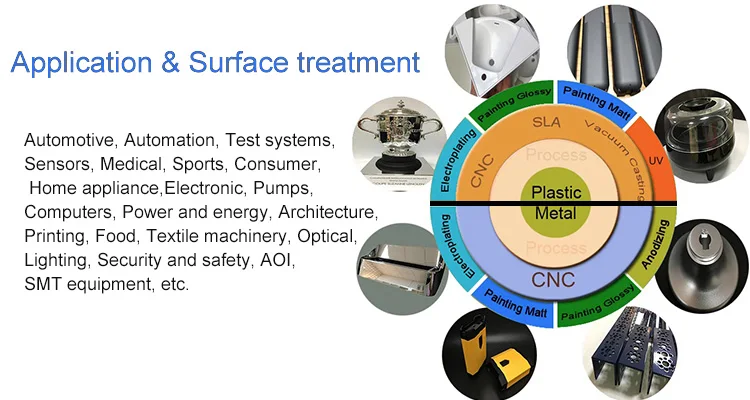

Car prototype,Architecture model ,Automotive, Automation, Test systems, Sensors, Medical,Sports,Consumer, Home appliance, Electronic , Pumps, Computers, Power and energy, Architecture,Printing,Food ,Textile ,Furniture,Commodity,Electronic etcmachinery,Optical,Lighting, Security and safety, AOI, SMT equipment, etc.

Product Name

|

3D printing prototype toys abs prototype manufacturing resin 3d printed action figures model pp nylon acrylic cnc machining |

Quotation |

According to your drawing(size, material, thickness, processing content and required technology, etc.) |

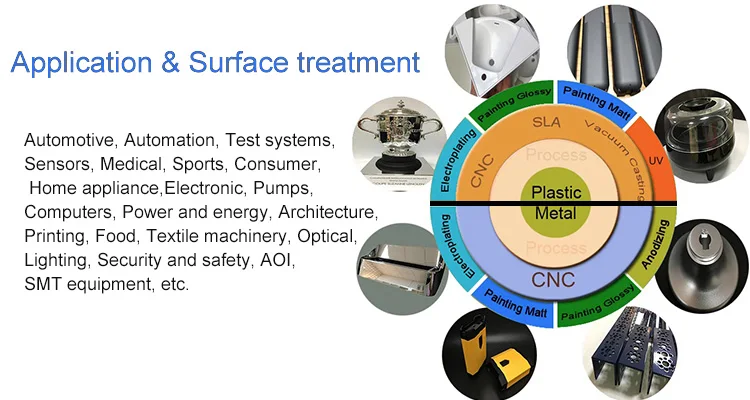

Application |

Car, Household Appliances,Furniture,Commodity,Electronic etc |

Processing |

CNC Turning, Milling parts, Drilling, Auto Lathe, Tapping, Bushing, Surface Treatment,etc. |

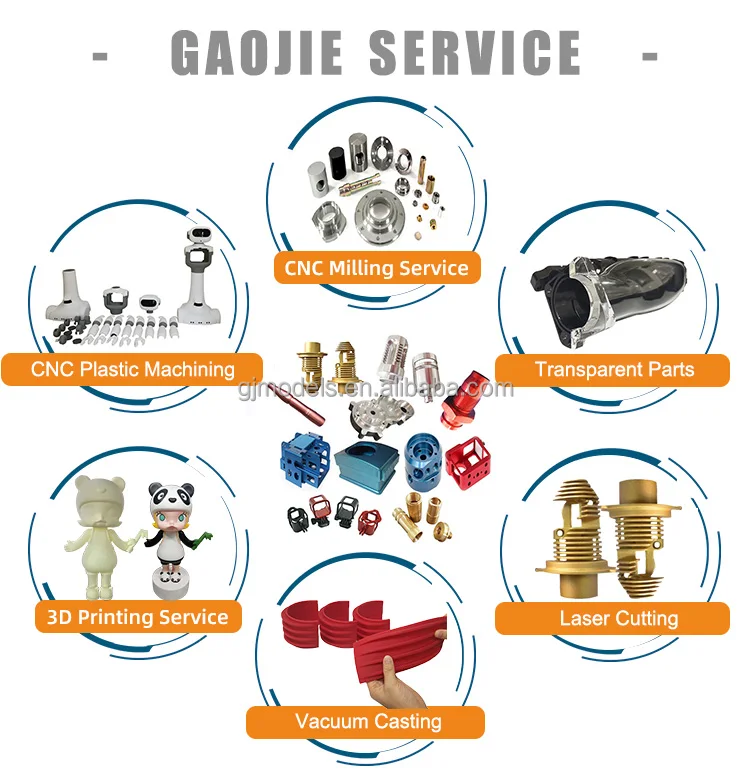

Available Service |

1.Design |

2. CNC Rapid Prototyping |

3. SLS/SLA/3D Printing Prototype Service |

4. High Precision CNC Machining |

5. Silicone Mold (Vacuum Casting) & Rapid Tooling |

Material |

Aluminum(6061,6063,mic6), stainless steel,brass,ABS,PC,POM, PP, PE, PA(Nylon),acrylic,wood,carbon fiber,copper, etc |

Surface treatment |

Polished, High polishing, Anodizing, Painting, Electroplating, Laser Engraving, Sand blasting, Brushed etc |

Drawing Format |

STEP File/PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF |

Anodized colors |

Do as pantone,Accept customization |

Tolerance |

±0.1mm |

MOQ |

1 piece |

Company Information

GuangZhou GaoJie Model Design And Manufacturing Co.,Ltd

GuangZhou GaoJie Model Design And Manufacturing Co.,Ltd was founded in 2008, focusing on rapid prototype manufacturing services, is a star company in Chinese prototype industry.

Our services include SLA, SLS, vacuum casting, CNC machining, rapid prototype, small batches prototypes, company is equipped with SLA,SLS, CNC machining center, CNC engraving and milling machine,lathe, milling machine, Vacuum Casting Machine and other rapid prototyping equipments.

Production Process

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts. Except plastics, metals we can manufacture are aluminum, stainless steel, brass and copper.

FAQ

Q1.What is the material?

A1.Plastics we can manufacture are ABS, PC,PMMA, PP, PA, PA+GF, PTFE etc, metals are aluminum, stainless steel, brass, copper etc.

Q2.Which surface treatment is available?

A2.Polishing, painting matt and glossy, UV coating, electroplating, silk screen, laser engraving, sand blasting, anodizing,

brushed,high polishing.

Q3.How long is the lead time?

A3.3-7 days.

Q6.What’s the tolerance of CNC?

A6.±0.1 to ±0.2 mm

Q8.How about your MOQ?

A8.1 piece.

custom toy car robot sample 3d printing rapid prototype car part for children unique birthday gift

EPOS Decision Vislon Enclosure Prototype,Mechanics Diagnostic Enclosure Prototype,Paint Thickness Gauge Enclosure Prototype,Medical Camera Enclosure Prototype,In Flight Entertanment Enclosure Prototype,Professional Navigation Enclosure Prototype,Data Logger Enclosure Prototype,Handheld Enclosure Prototype,Comms Enclosure Prototype,

EPOS Display Enclosure Prototype,Podd Enclosure Prototype,Medical Diagnostics Enclosure Prototype,Taxi Enclosure Prototype,Casino Display Enclosure Prototype,Thermo Scientific Enclosure Prototype,Taxi Meter Enclosure Prototype,Gas Detector Kit Enclosure Prototype,Police Handheld Enclosure Prototype,Robot Enclosure Prototype,Digital Camera Enclosure Prototype