High Quality Gyratory Compass Vibrating Screen Aggregate Separation Equipment/Spin Vibration Screening Machine

- Category: >>>

- Supplier: Henan Chunying Environmental Protection Equipment Co. Ltd.

Share on (1600449776239):

Product Overview

Description

Product Description

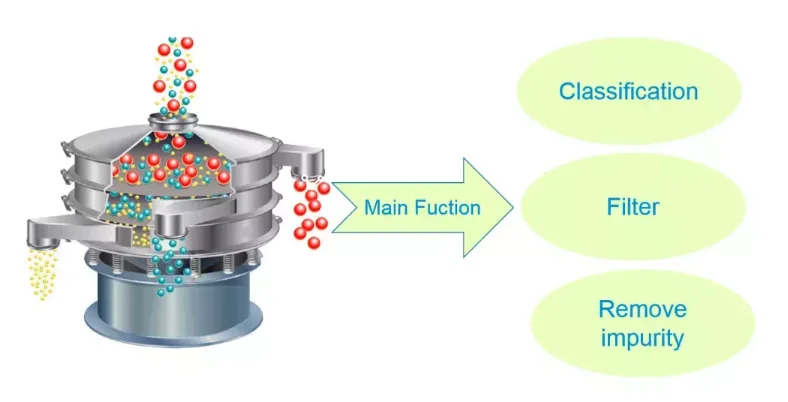

Vibrating Sifter is a kind of mature technology,general and tend to be standardized classic inertia screening equipment.It can meet the requirement of most materials in grading granulated stuffs and screening out powder and liquid in different

operation.High screening efficiency,it adopts whole sealing structure design which can avoid polluting effectively.The direction of outlet port can be changed within 360 degrees.We can provide customized service according to customers' requirements.

Working Principle

When the machine begins running,the operation of the vibrating motor generates exciting force,then under the power of exciting

force,the machine body do compound movement,last,the materials on the sieve mesh do jumping movement with the machine body.

Why Choose Us

Application

Chemical industry: resin pigment, calcium carbonate, decorative coatings, medicine, grease, paint, palette, etc.

Abrasive material and ceramic industry: building sand, mica, alumina, silica sand, abrasive, refractory material, slurry, etc. Food industry: sugar, salt, alkali, flour powder, nut powder, whey protein powder , maltodextrin , flavors , sucralose , xanthan gum, soy lecithin farina, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc. Paper-making industry coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

Metallurgy and mining industry: quartz sand, sand, ore, titanium oxide, zinc oxide, etc.

Mechanical industry: casting sand, charcoal, grafito, powder metallurgy,electromagnetic material and metal powder, etc

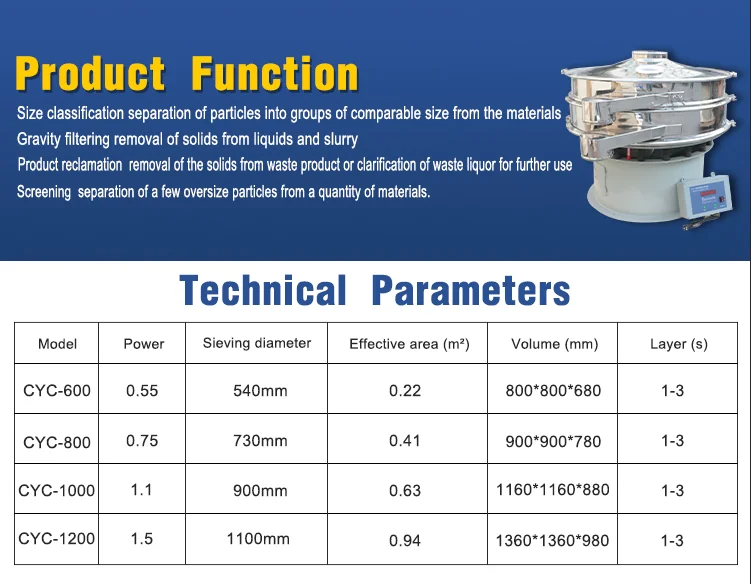

Product Parameters

How To Choose Suitable Model?

1. If you have ever used the screen machine, kindly pls tell us its DIAMETER, LAYERS, MESH SIZES, MATERIALS.

2. If never use the machine until now, pls offer us the info about material as below:

2.1. Handling material? Bulk density?

2.2. Will you do a separation or dust-removal?

2.3. Production Capacity per hour(KG/H)?

2.4. How many Layers do you need? Mesh size of each layer?

2.5. Material of Construction material?(Stainless steel or Mild Steel)

2.6. Voltage(V), Frequency(Hz), Phase(P)?

Customer site

Packing & Delivery

FAQ

Q:What factors I need to get a quotation?

A: Name & bulk density of materials;Capacity per hour;Mesh size and decks;Material of themachine;Voltage&Frequency(Hz).

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based

on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the

damage could be repaired by slight cost, we wouldwait for the customer's bill for the fix cost and refound this part of

cost.(note: Vulnerable parts do not include.)

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices