Full automatic dual wave soldering machine on line selective soldering machine for DIP line

- Category: >>>

- Supplier: Shenzhen Oubel Technology Co. Ltd.

Share on (1600508929922):

Product Overview

Description

Product Description

Full automatic dual wave soldering machine on-line selective soldering machine for DIP line

Features of PCB Selective Soldering Machine:

1. PCB plate fixed, spray and soldering platform moving.

2. High soldering quality, greatly improve the pass rate of soldering.

3. Modular design of SMEMA online transportation, support customers for flexible line formation.

4. Full PC control. All parameters can set in PC and saved to PCB menu, like moving path, solder

temperature, flux type, solder type ,n2 temperature etc, best trace-ability and easy to get repeat soldering quality.

5. Auto wave height calibration function, to check & calibrate wave’s height after every certain pcb, so to keep a very good stability of wave.

6. Can upgraded to be with Mark positioning function, to check PCB’s mark point after every certain pcb.

7. Self design motion table with cast aluminum, lighter weight with quick motion speed.

8. Panasonic servo motor & driver provide stable, with ball screw & linear guild rail.less noise, stable movement.

9. With dust proof plate above motion table, so to avoid flux or solder drop to damage ball screw.

10. The jet valve originated in Germany is selected with small flux dot, please note flux solid content should be less than 10%.

Working process:

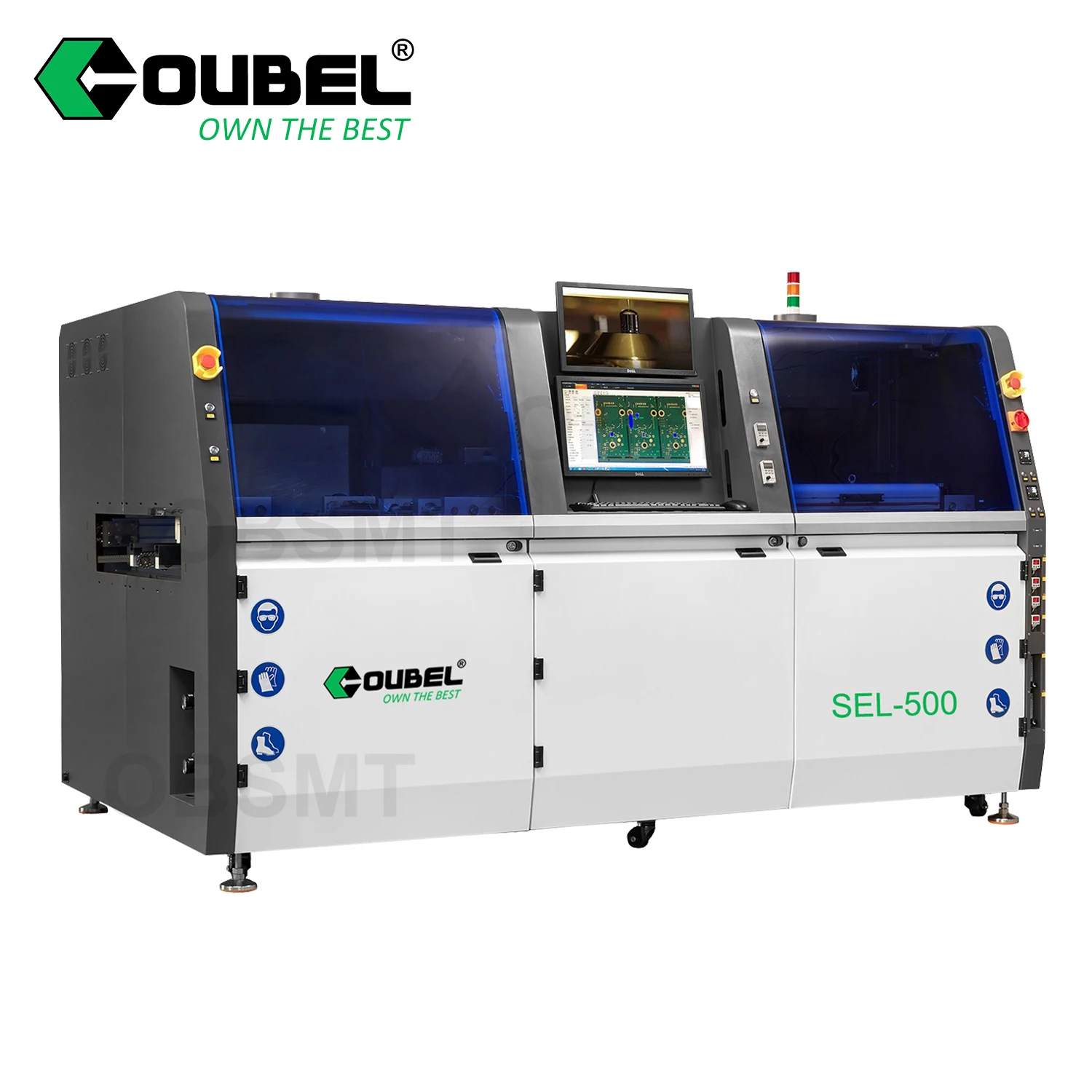

Model | SEL-500 |

Preheating mode | IR heating |

Preheating zone | Top hot air:1 Bottom IR: 1 |

Flux Storage Tank | 3L |

Max. PCB size | 500*500mm |

Operater Power | 7-10Kw |

Power Supply | 380±10%, 50/60HZ, 25Kw |

Dimensions | L2860*W1650*H1650mm |

Weight | 1600KGS |

Flux Spraying System:

1.Standard with imported jet valve to get precious fluxing result with small flux dot, please note flux solid content should be less than 10%.

2.Flux is stocked by pressure tank, make sure pressure stable without influenced of amount of flux. The nozzle jam detection function is optional.

3.The XY spray platform is composed of high-precision ball screw and linear slide rail. It is driven by a high-speed servo motor.

2.Flux is stocked by pressure tank, make sure pressure stable without influenced of amount of flux. The nozzle jam detection function is optional.

3.The XY spray platform is composed of high-precision ball screw and linear slide rail. It is driven by a high-speed servo motor.

Preheating System:

Bottom preheating is standard equipped in machine, Position is adjustable.IR heater of Top,Efficient and stable IR heat

conduction.Design structure for maximizing preheating area. All round high temperature cotton design to ensure temperature stability.

conduction.Design structure for maximizing preheating area. All round high temperature cotton design to ensure temperature stability.

Heat-generating and heat-conducting parts and motors adopt top brands.

Maintenance plug-in design. tool-free maintenance mode.

Soldering System:

1.XYZ platform is composed of high precision ball screw and high-speed motor.

2.Electromagnetic pump coil adopts German imported brand to ensure the stability and reliability of the peak.

3.Solder temperature, N2 temperature, wave height, wave calibration etc all able to set in software.

4.Standard with the nozzle automatic cleaning function. How many panels can be set to clean the nozzle.

Transmission system:

The transmission module is composed of three parts by roller.

The spray and soldering transmission tracks are equipped with a stop plate positioning device to ensure the accuracy.

The distance of weldable elements on PCB plate edge is much higher than that of chain conveyor structure.

The spray and soldering transmission tracks are equipped with a stop plate positioning device to ensure the accuracy.

The distance of weldable elements on PCB plate edge is much higher than that of chain conveyor structure.

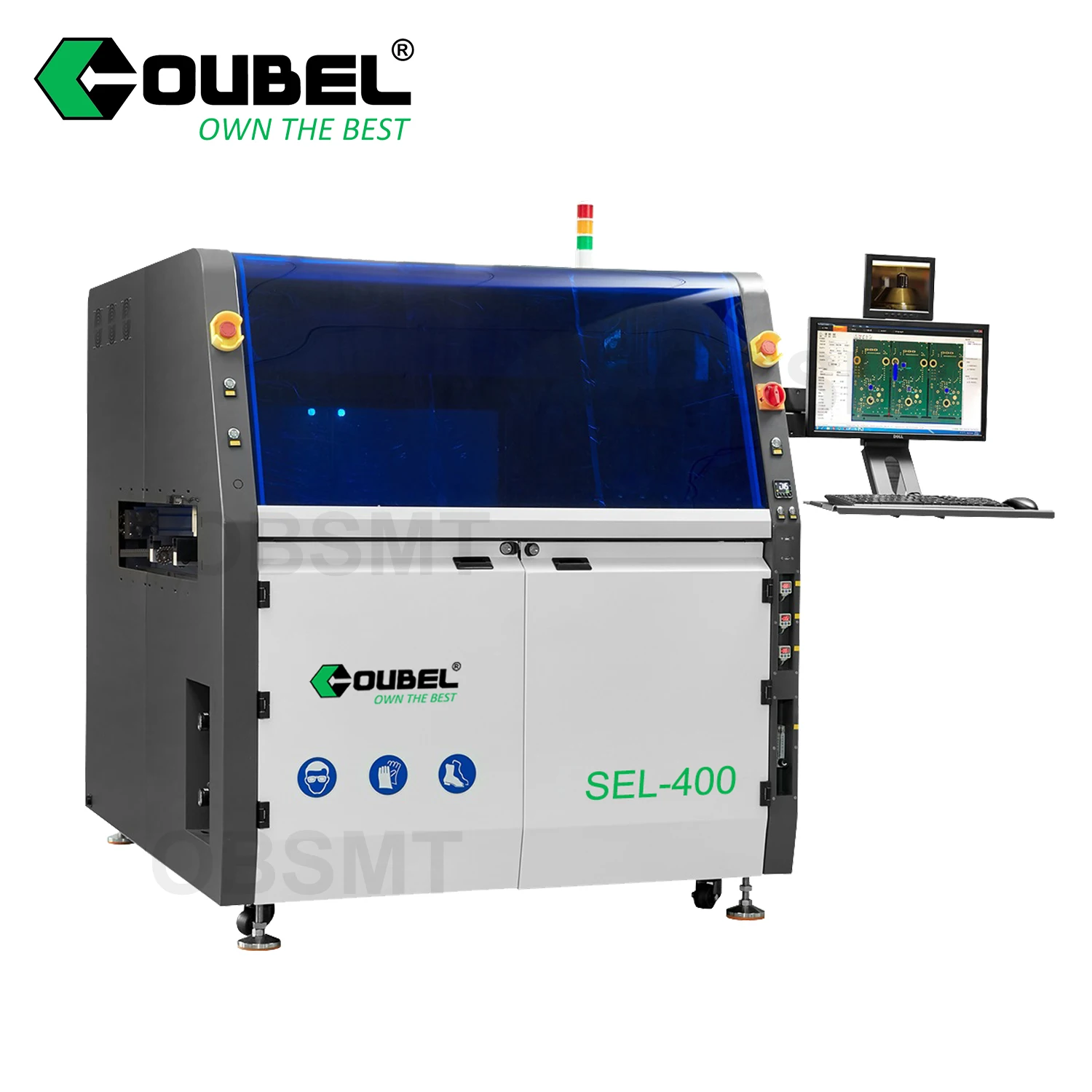

Related Product

Packing&Delivery

Company Profile

Shenzhen Oubel Technology Co.,Ltd.

Oubel supplies the dispensing and PCB conformal coating machine, SMT &DIP machines that is supported by a global service network,we offer customer-inspired solutions in a range of industries. OUBEL is dedicated to making quality products that help our clients operate more efficiently and effectively. Oubel is guided by the principles of fairness to our suppliers, associates,clients and employees, and helping them achieve to the best of their potential.

Clients feedback

FAQ

1.Are you a trade company or a manufacture?

We are a manufacturer,OEM & ODM service are available.

2.What is your delivery date?

The delivery date is about 3-5 days after receipt of payment.

3.What is your payment terms?

Accept payment by T/T,Paypal,Alibaba.

4.Can you provide a whole line solution?

Yes, we can.We can supply SMT line,Coating line,DIP line and LED production line.

We are a manufacturer,OEM & ODM service are available.

2.What is your delivery date?

The delivery date is about 3-5 days after receipt of payment.

3.What is your payment terms?

Accept payment by T/T,Paypal,Alibaba.

4.Can you provide a whole line solution?

Yes, we can.We can supply SMT line,Coating line,DIP line and LED production line.

Contact Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices