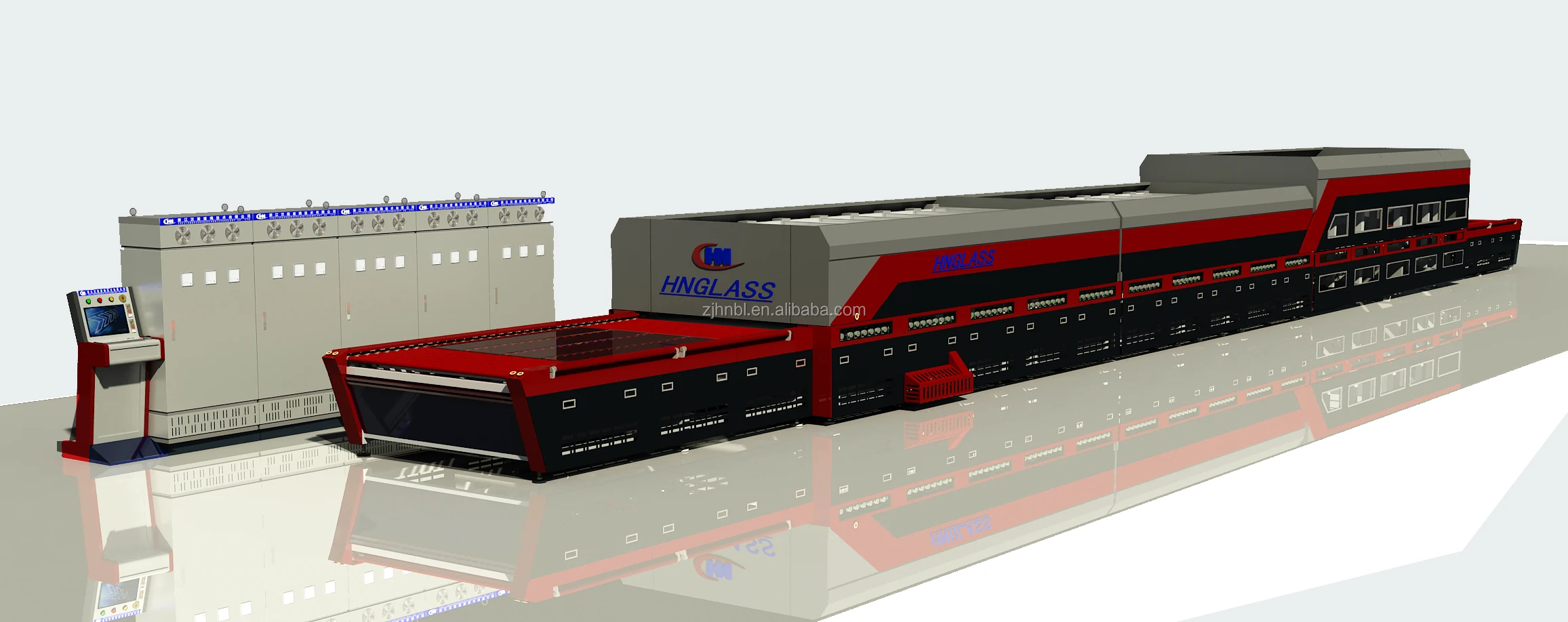

Roller glass coating machine

US $30000

Share on (1600513447970):

Model | Max Glass Size mm | Min Glass Size mm | Glass Thickness mm | Productivity (Batch/hour) | Installation Power KW |

HNTA1225 | 1250×2500 | 100×250 | 3-19 | 22 | 150 |

HNTA1236 | 1250×3660 | 100×250 | 3-19 | 22 | 230 |

HNTA1625 | 1600×2500 | 100×250 | 3-19 | 22 | 220 |

HNTA1636 | 1600×3660 | 100×250 | 3-19 | 22 | 300 |

HNTA2030 | 2000×3000 | 100×250 | 4-19 | 18 | 315 |

HNTA2036 | 2000×3600 | 100×250 | 4-19 | 18 | 400 |

HNTA2042 | 2000×4200 | 100×250 | 4-19 | 18 | 450 |

HNTA2436 | 2440×3660 | 200×300 | 4-19 | 18 | 500 |

HNTA2442 | 2440×4200 | 200×300 | 4-19 | 18 | 550 |

HNTA2450 | 2440×5000 | 200×300 | 4-19 | 18 | 650 |

HNTA2460 | 2440×6000 | 200×300 | 4-19 | 18 | 800 |

HNTA2480 | 2440×8000 | 200×300 | 4-19 | 18 | 1000 |

HNTA2860 | 2800×6000 | 200×350 | 5-19 | 15 | 900 |

HNTA2880 | 2800×6000 | 200×350 | 5-19 | 15 | 1200 |

HNTA28150 | 2800×15000 | 200×350 | 5-19 | 15 | 2200 |

HNTA3380 | 3300×8000 | 200×500 | 6-19 | 14 | 1500 |

HNTA33160 | 3300×16000 | 200×350 | 6-19 | 14 | 2800 |

HNTA3580 | 3500×8000 | 200×500 | 6-19 | 14 | 1600 |

New products from manufacturers at wholesale prices