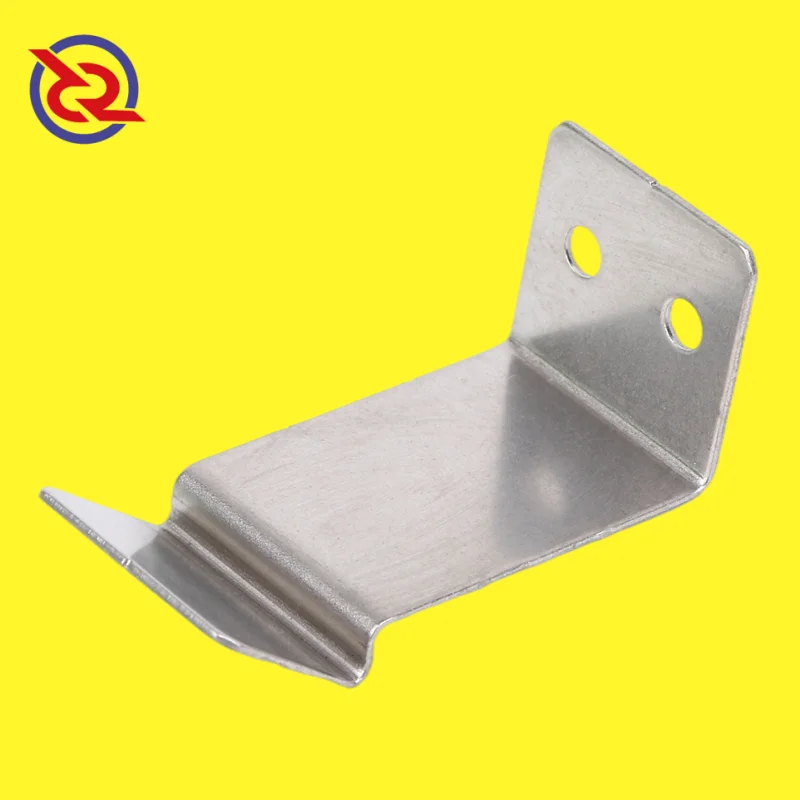

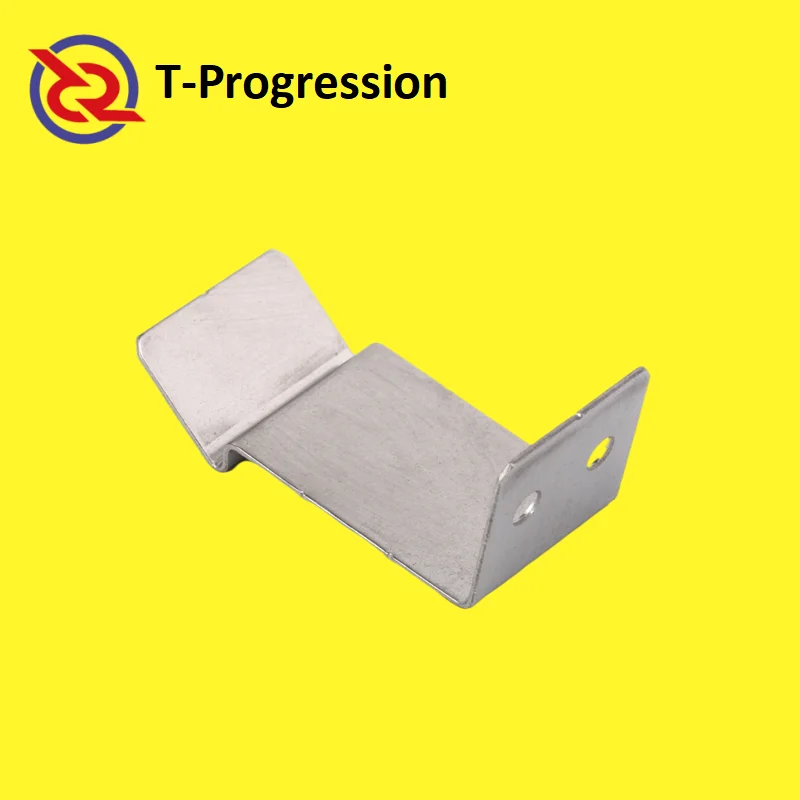

Stamping Factory Custom Small Progressive Metal Stamping Components Made By Progressive Mold Cr2032 Battery Contact Shrapnel

- Category: >>>

- Supplier: T-Progression Machine (Shenzhen) Ltd.

Share on (1600524572449):

Product Overview

Description

Factory

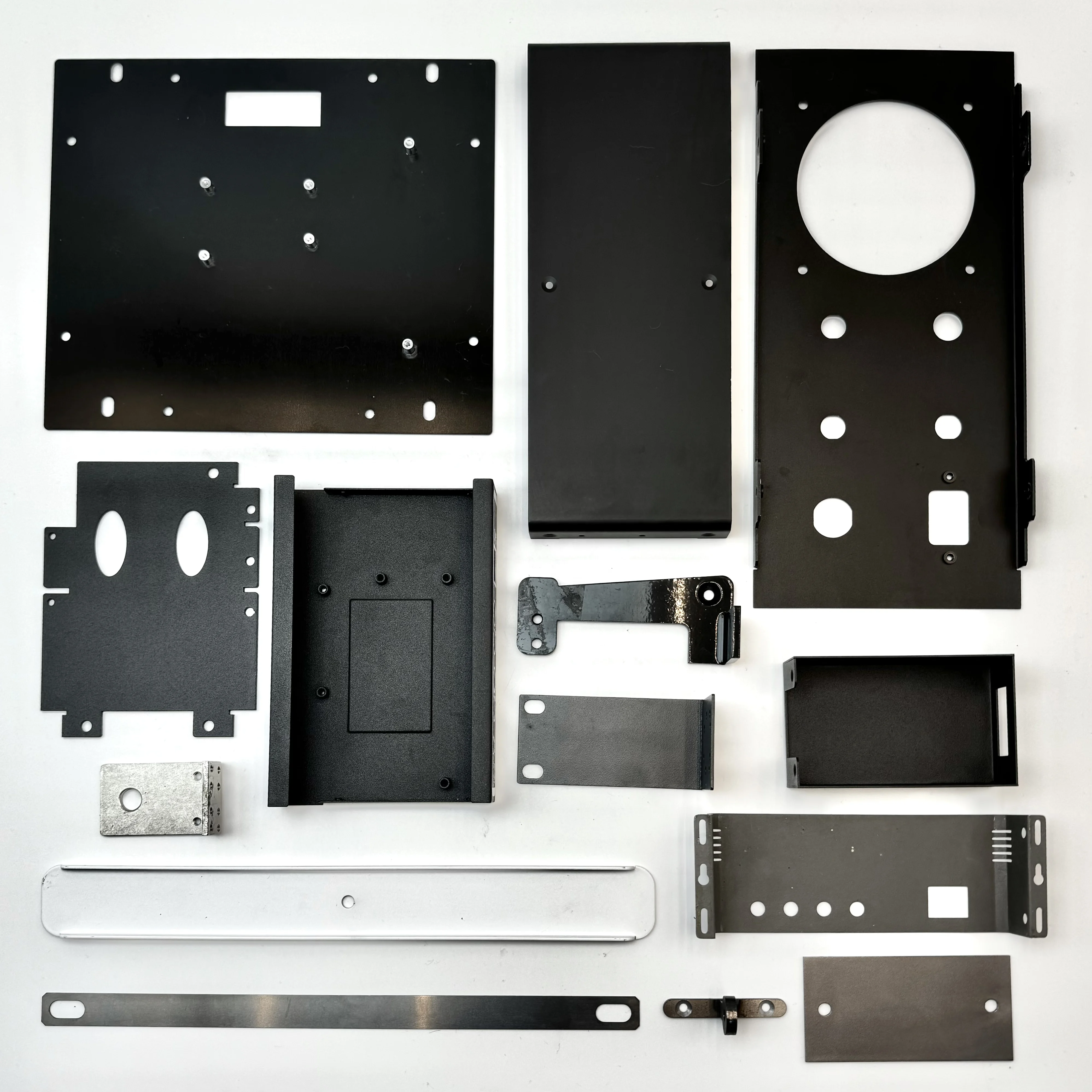

Product Description

Dimensions | customized | ||||||

Material | SPCC,SECC,SGCC,stainless steel,brass,aluminum,carbon steel,alloy steel etc. | ||||||

Surface treatment | plating,anodized,power coating,polished,painting, gilding,electrophoresis,brushing, frosted etc. | ||||||

Packaging | opp bag,cardboard, foam, k=k carton etc. or according to customer’s information. | ||||||

OEM&OEM | Accepted | ||||||

Sample time | 7 days and free if standard parts we have | ||||||

Drawing format | PDF, STP,STEP,DWG, CAD | ||||||

Process | staming, punching,forming,doming,ring cutting,deep drawing,bending,,welding,riveting,tapping,assembling | ||||||

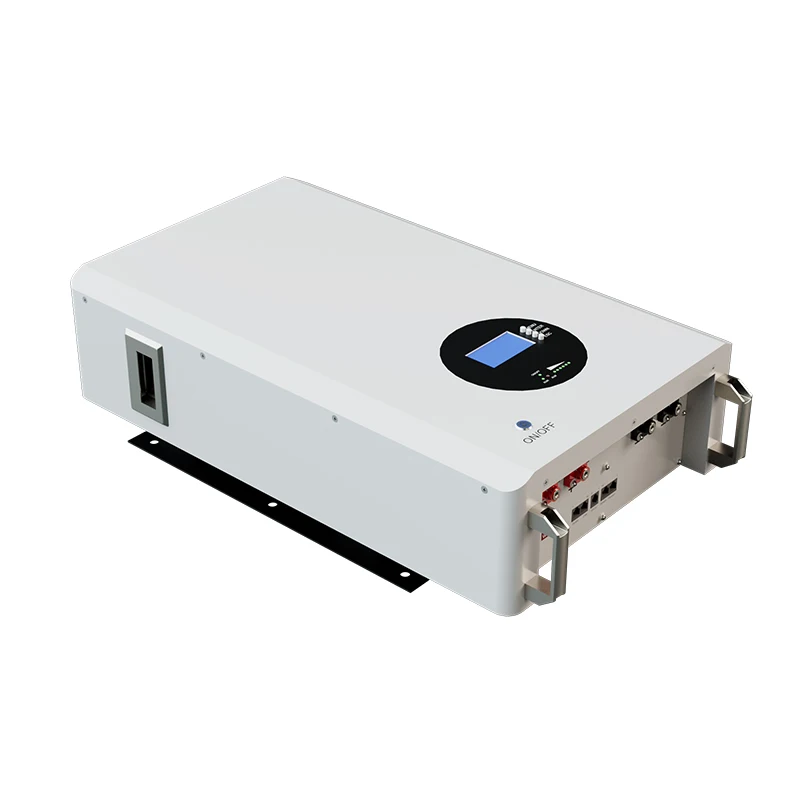

Product & Company Profile

Our Quality Control

Our Main Partners&Our Good Reviews

Packing&Delivery

FAQ

Q: Are you a factory or trading company?

A:T-progression is a 20+ years experience factory in Shenzhen of China,welcome to visit us.

Q: What are your main products?

A:We specialize in manufacturing metal stamping parts, sheet metal fabrication, metal stamping mold design&making, shrapnel, high precision hand samples and assembly products.

Q: Do you receive OEM/ODM?

A:Yes.We have a professional engineer team to support 0EM/ODM work.

Q: How can I get the quotation?

A:We will submit the quotation within 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

(1)3D Step of Files and 2D Drawings(2)Material requirement(3) Surface treatment(4)Quantity(per order/per month/annual)

(5) Any special demands or requirements, such as packing,labels, delivery, etc.

Q: Can I get the samples?

A:Yes, sample order is avallable for quality check and market test and it will be freight collected payment.If simple sample.we will not charge cost;

Q: How do you do the quality control?

A:(1).Materials inspection by IQC.

(2).During processing, our IPQC will check the injection molded parts all the time (3).FQC will check the products before sending to the warehouse(4).100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective products, please send us the photoes,we will feedback to our engineers and QC departments and solve the problems ASAP.

A:T-progression is a 20+ years experience factory in Shenzhen of China,welcome to visit us.

Q: What are your main products?

A:We specialize in manufacturing metal stamping parts, sheet metal fabrication, metal stamping mold design&making, shrapnel, high precision hand samples and assembly products.

Q: Do you receive OEM/ODM?

A:Yes.We have a professional engineer team to support 0EM/ODM work.

Q: How can I get the quotation?

A:We will submit the quotation within 24 hours if getting detailed information during working days. In order to quote for you earlier, please provide us the following information together with your inquiry:

(1)3D Step of Files and 2D Drawings(2)Material requirement(3) Surface treatment(4)Quantity(per order/per month/annual)

(5) Any special demands or requirements, such as packing,labels, delivery, etc.

Q: Can I get the samples?

A:Yes, sample order is avallable for quality check and market test and it will be freight collected payment.If simple sample.we will not charge cost;

Q: How do you do the quality control?

A:(1).Materials inspection by IQC.

(2).During processing, our IPQC will check the injection molded parts all the time (3).FQC will check the products before sending to the warehouse(4).100% inspected by OQC before shipping out.

Q: What should we do if we receive defective products?

A: If receive defective products, please send us the photoes,we will feedback to our engineers and QC departments and solve the problems ASAP.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices