Industrial Alcohol Recovery Short Path Steam Ethanol Distillation Equipment Alcohol Units Distiller For Sale

- Category: >>>

- Supplier: Shanghai Minjie Machinery Co. Ltd.

Share on (1600535263355):

Product Overview

Description

Product Overview

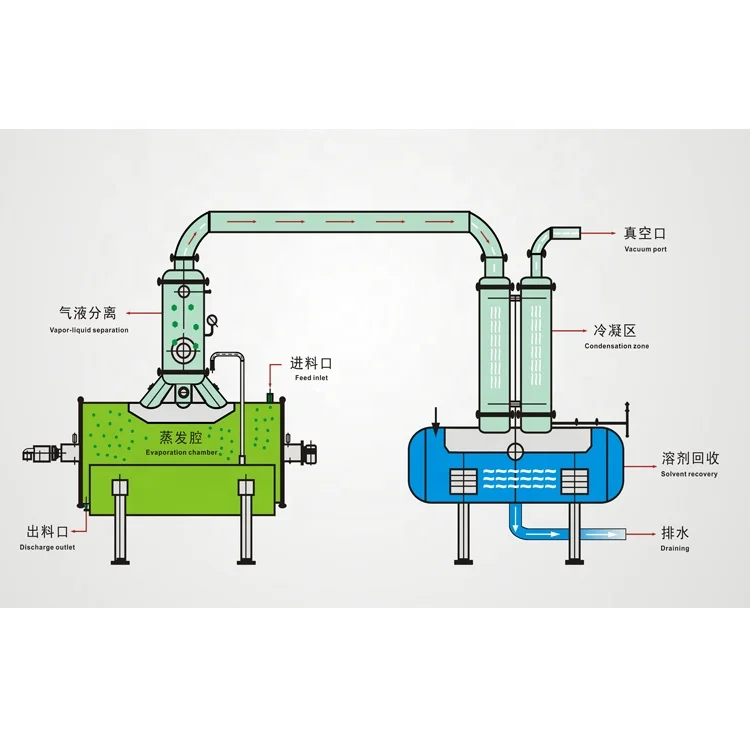

Low-temp Vacuum Evaporator

Low-temp Vacuum Evaporator featured with continuous feed and discharge, the whole operation is under high vacuum and low temperature state, so it is especially suitable for liquid with temperature-senstive, as active ingredients of the raw material can be kept. it is used widely in food pharmaceutical, chemical industries,and so on

1.Automatic Continuous feed and discharge 2.under vacuum state,low temperature.

3.Protect the active ingredients of raw material

4.Adjustable concentration temperature(20-50℃)

5.No density limits, as long as with fluidity

6.Online density monitor, automatic discharge

7.CIP system, quick & thorough cleaning, no dead corner

8.Solvents recovery

9.GMP standards

3.Protect the active ingredients of raw material

4.Adjustable concentration temperature(20-50℃)

5.No density limits, as long as with fluidity

6.Online density monitor, automatic discharge

7.CIP system, quick & thorough cleaning, no dead corner

8.Solvents recovery

9.GMP standards

Model selection referencce

Model | Heating area ㎡ | Evaporation capacity kg/h | Vacuum degree MPa | Heating media | Density before concentration | Main dryer power kw | Weight kg | Outline dimension m |

MJ-NS-3 | 3 | 60-100 | -0.098 | Hot water | With fluidity,density not restricted | 3.9 | 1500 | 3.8×1×3.6 |

MJ-NS-5 | 5 | 150-200 | 5.2 | 2200 | 5.2×1×4.2 | |||

MJ-NS-10 | 10 | 300-400 | 60-75 | 6 | 3000 | 6.5×1.2×4.2 | ||

MJ-NS-15 | 15 | 500-600 | 80-90 | 8.5 | 3800 | 6.5×1.2×4.5 | ||

MJ-NS-20 | 20 | 600-800 | 100-110 | 11 | 5000 | 6.5×4×4.6 | ||

MJ-NS-30 | 30 | 800-1000 | 120-140 | 13 | 7000 | 8*2.1*5.5 |

Application

1. food and beverage such as instant tea /cocoa powder/Molasses/Honey/Camel Milk/Malted milk drink/ovaltine powder

2. Pharmaceutical such as Herbal Medicine/Plant Extract/Pills

3. Chemical such as Lithium Battery Fluid/Polymer battery/Cobalt products/Copper products/Agricultural chemicals/Hazardous Chemical

Details Images

Our Advantages

FAQ

Question 1: What is the working principle of vacuum belt dryer?

Answer: Vacuum belt dryer is a continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated under low temperature, thus protect active ingredients in the product.

Question 2: What is the cleaning way? Whether does the machine accord with GMP standards?

Answer: with CIP cleaning, vacuum belt dryer is the best choice for GMP performance.

Question 3: What kind of products can vacuum belt dryer dry?

Answer: all kinds of liquid material for vacuum belt dryer.

Question 4: How to ship vacuum belt dryer?

Answer: Flat Rack+container

Question 5:What is the delivery time?

Answer: 90-120 days

Question 6: What is the after-sales service type?

Answer: engineers onsite to guide installation, commissioning and training.

Question 7:How many years history of your factory?

Answer: Since 1998.

Question 8:How many sets vacuum belt dryer are been sold every year?

Answer: 80-100 sets

Question 9: What is drying temperature?

Answer: 30-150℃(adjustable)

Answer: Vacuum belt dryer is a continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated under low temperature, thus protect active ingredients in the product.

Question 2: What is the cleaning way? Whether does the machine accord with GMP standards?

Answer: with CIP cleaning, vacuum belt dryer is the best choice for GMP performance.

Question 3: What kind of products can vacuum belt dryer dry?

Answer: all kinds of liquid material for vacuum belt dryer.

Question 4: How to ship vacuum belt dryer?

Answer: Flat Rack+container

Question 5:What is the delivery time?

Answer: 90-120 days

Question 6: What is the after-sales service type?

Answer: engineers onsite to guide installation, commissioning and training.

Question 7:How many years history of your factory?

Answer: Since 1998.

Question 8:How many sets vacuum belt dryer are been sold every year?

Answer: 80-100 sets

Question 9: What is drying temperature?

Answer: 30-150℃(adjustable)

We Recommend

New Arrivals

New products from manufacturers at wholesale prices