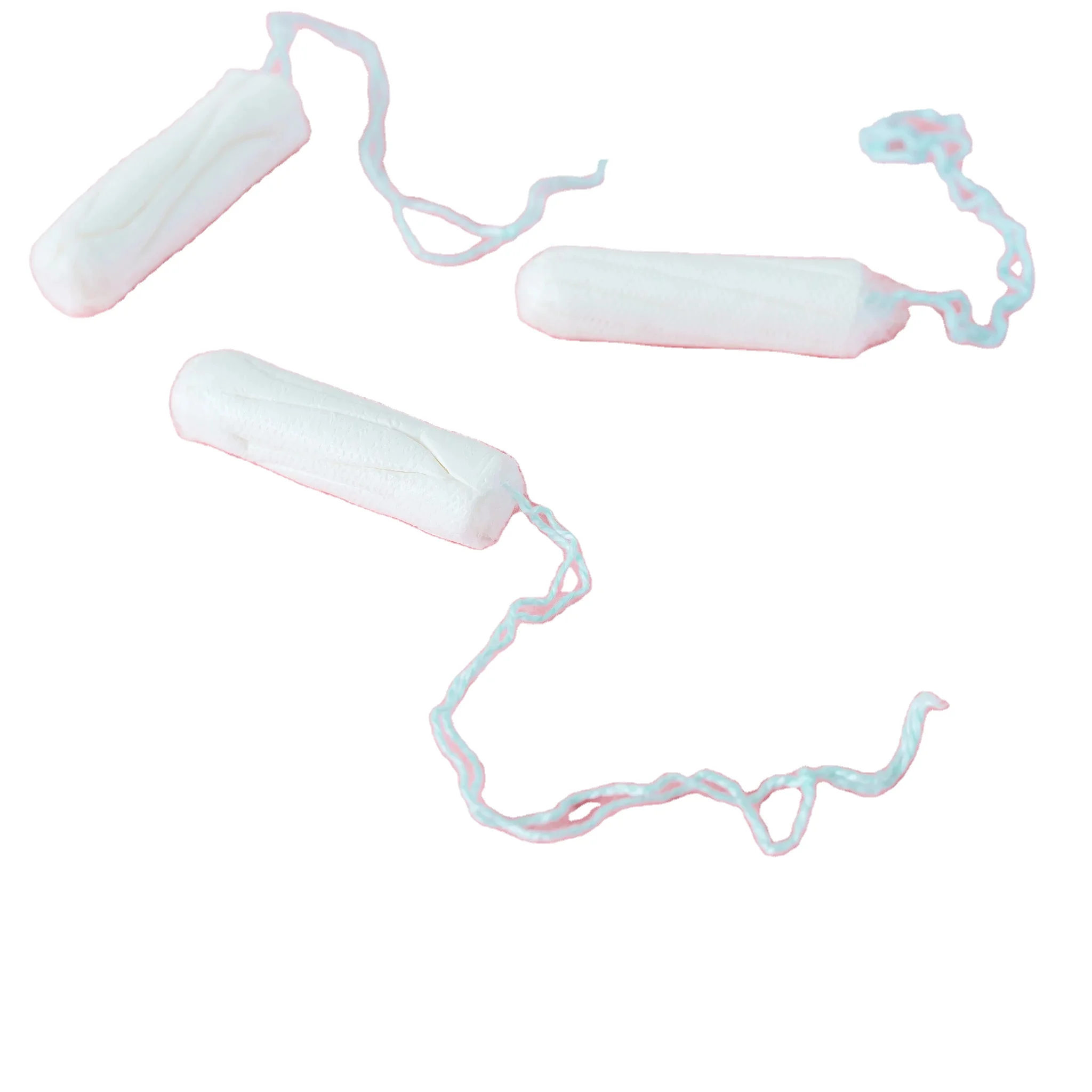

wholesale reusable ob organic tampons applicator private label cotton for women with applicator

- Category: >>>

- Supplier: DH (Shandong) Health Technology Co. Ltd.

Share on (1600536244974):

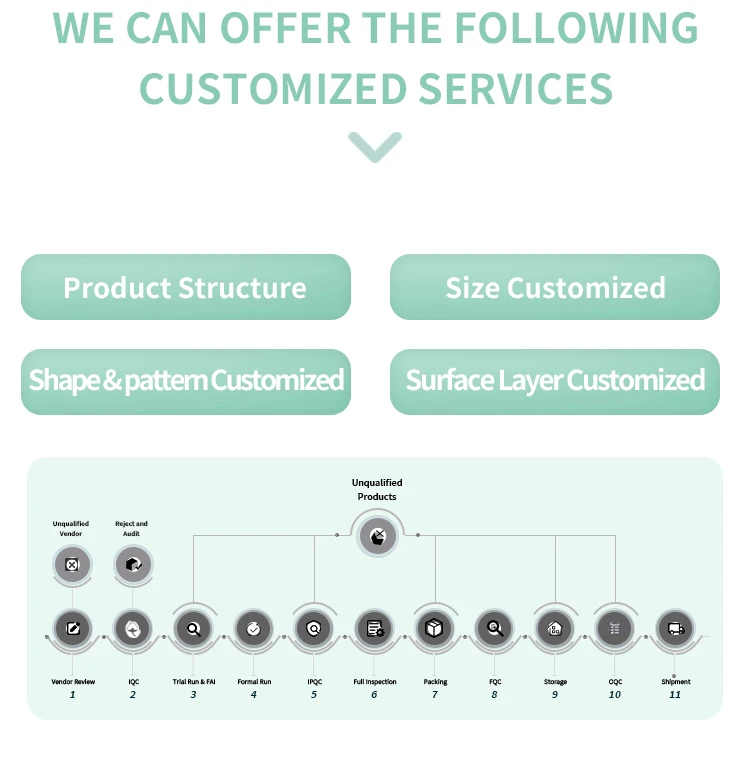

Product Overview

Description

Types of Tampon | Digital Tampon | ||

Compact tampon | |||

Pearl applicator tampon | |||

Color | White | ||

Material | 2 tubes + String | ||

Raw Material | Rayon / Cotton / Complex | ||

Brand Name | ODM/OEM | ||

Style | Digital, Applicator, Compact Tampon | ||

Samples | Free sample could be available | ||

OEM/ODM | Welcomed | ||

MOQ | 1 piece | ||

Package | Packing Method | 8/12/16/32/48/100 pcs / bag / box / carton | |

Packing Material | PE/Paper or Customized | ||

Delivery | Delivery | 7-25Days | |

Delivery port | Qindao,China | ||

Term of Payment | T/T 30% as the desposit,70% before shipment | ||

L/C/D/P/D/A/West Union, MoneygGram, Other | |||

Features | Fully fit, Effectively prevent leakage, Not easy to penetrate, Place no sense, Soft touch, Small and convenient, Comfortable and convenient, Freedom of movement, Breathable, Strong by gravity, Large absorption, Eco-friendly and natural. | ||

Application | Biodegradable organic cotton tampons for women. | ||

FAQ

1. The design of the artwork.

The artwork design is generally based on the sample or drawing provided by the customer to draw the production artwork.

Generally,drawing software, such as CDR or Al software, is used. If the customer cannot provide the sample, we can follow the customer's request and cooperate with the customer for free. Slightly designed and produced.

2. Make mold.

According to the designed artwork, the steel mold is produced. The production technology of the mold of some silicon rubber products is relatively high, and the time is relatively longer. Generally, the mold opening period is calculated according to five days, and the mold is completed within 7-15 days. After the proofing board confirms that the structure is correct, mass production can be produced.

3. Toning

According to the customer's specified color or according to the customer's sample color, our company's color ratio is

aligned(above 95%), and the color difference is very small.

4. Approved materials

According to the requirements of customers, it is produced with different silicone raw materials. If there are domestic ordinary rubber materials, high tensile (gas rubber), imported rubber materials, the hardness of silica gel ranges from 30 degrees to 80degrees, and 60 degrees are commonly used. The company has professional instruments to measure.

5. Upper mold production

Send the colored silica gel raw materials to the production department for production.

6. Product inspection

Perform a full inspection on the first product produced, whether it meets the product specifications, whether it matches the color required by the customer, whether it is dirty or lacks material, and other appearance defects. If there is any discrepancy, all will be discarded.

7. Trimming

Each product will be produced with a phoenix. After the raw product has passed the inspection and inspection, the product will be sent to the process department for phoenix treatment. After the phoenix is processed, it is the finished product.

8. Appearance function inspection

Send the finished product to the quality inspection department for inspection to see if there is any poor handling of the

front,etc., after the inspection is passed, the tensile, torsion, UV, and other functional tests are performed.

9. Packaging

After all, products are tested and qualified, they are assembled with different colors of silicone semi-finished products

according to customer requirements, and then packaged (note: different packaging, different charges).

10. Outgoing QC Control

After the packaging is completed, the quality inspection department will check whether the label, color, quantity, etc. of each box are consistent with the order. If no problem, the box will be sealed and deliver to you.

Generally,drawing software, such as CDR or Al software, is used. If the customer cannot provide the sample, we can follow the customer's request and cooperate with the customer for free. Slightly designed and produced.

2. Make mold.

According to the designed artwork, the steel mold is produced. The production technology of the mold of some silicon rubber products is relatively high, and the time is relatively longer. Generally, the mold opening period is calculated according to five days, and the mold is completed within 7-15 days. After the proofing board confirms that the structure is correct, mass production can be produced.

3. Toning

According to the customer's specified color or according to the customer's sample color, our company's color ratio is

aligned(above 95%), and the color difference is very small.

4. Approved materials

According to the requirements of customers, it is produced with different silicone raw materials. If there are domestic ordinary rubber materials, high tensile (gas rubber), imported rubber materials, the hardness of silica gel ranges from 30 degrees to 80degrees, and 60 degrees are commonly used. The company has professional instruments to measure.

5. Upper mold production

Send the colored silica gel raw materials to the production department for production.

6. Product inspection

Perform a full inspection on the first product produced, whether it meets the product specifications, whether it matches the color required by the customer, whether it is dirty or lacks material, and other appearance defects. If there is any discrepancy, all will be discarded.

7. Trimming

Each product will be produced with a phoenix. After the raw product has passed the inspection and inspection, the product will be sent to the process department for phoenix treatment. After the phoenix is processed, it is the finished product.

8. Appearance function inspection

Send the finished product to the quality inspection department for inspection to see if there is any poor handling of the

front,etc., after the inspection is passed, the tensile, torsion, UV, and other functional tests are performed.

9. Packaging

After all, products are tested and qualified, they are assembled with different colors of silicone semi-finished products

according to customer requirements, and then packaged (note: different packaging, different charges).

10. Outgoing QC Control

After the packaging is completed, the quality inspection department will check whether the label, color, quantity, etc. of each box are consistent with the order. If no problem, the box will be sealed and deliver to you.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices