20KV 30KV 60KV Static Generators Charging Bars Static Electricity Generator for Film

- Category: >>>

- Supplier: Xian Decai Honorise New Material Co. Ltd.Xian Ltd.

Share on (1600544453013):

Product Overview

Description

20KV 30KV 60KV Static Generators Charging Bars Static Electricity Generator for Film

The electrostatic generator mainly generates static electricity. The output is usually single polarity, such as positive or negative polarity, and the output voltage can be adjusted. It is usually used in scientific research, electrostatic applications such as injection molding film production industry, electrostatic spraying, and electrostatic field generation. For biological effect studies and other places where electrostatics are to be applied

DECAI Static Electricity Generator Features:

1. Good spraying quality: The paint particles with static electricity have strong adsorption capacity, and the rough surface of the workpiece and the dead corners can be painted evenly, which solves the problems of uneven thickness and color difference of the hand-sprayed paint film, and the quality is more stable.

2. Reduce the cost of paint: The excellent adsorption characteristics of static electricity make the painting rate reach more than 95%, which saves 30% - 50% of paint compared with ordinary hand spraying, and greatly reduces the production cost.

3. High efficiency: The electrostatic spraying time is short, the coating is uniform, and it can reach 50-100um in a few seconds. The thickness of the coating fully meets the customer's production requirements, and the efficiency of the assembly line lifting system is improved several times, while saving human resources.

4. Safe and long service life.

1. Good spraying quality: The paint particles with static electricity have strong adsorption capacity, and the rough surface of the workpiece and the dead corners can be painted evenly, which solves the problems of uneven thickness and color difference of the hand-sprayed paint film, and the quality is more stable.

2. Reduce the cost of paint: The excellent adsorption characteristics of static electricity make the painting rate reach more than 95%, which saves 30% - 50% of paint compared with ordinary hand spraying, and greatly reduces the production cost.

3. High efficiency: The electrostatic spraying time is short, the coating is uniform, and it can reach 50-100um in a few seconds. The thickness of the coating fully meets the customer's production requirements, and the efficiency of the assembly line lifting system is improved several times, while saving human resources.

4. Safe and long service life.

The electrostatic generator has over-current and short-circuit protection functions. The discharge to the ground is “not ignited”, and the ground or the workpiece is too close. The worker accidentally touches the automatic shutdown system and has a high safety factor.

The static electricity generator has been verified by many enterprises and manufacturers, and has excellent performance and long service life. It is widely used in bicycles, automobiles, motorcycles, home appliances, hardware products, wood furniture and other industries.

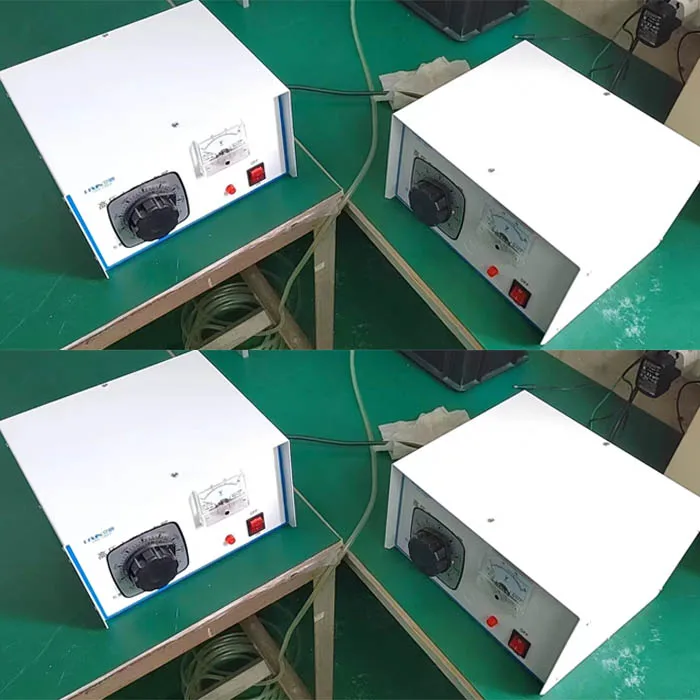

IML Static Generator Specification | ||||||||

Name | In Mold Labeling(IML )Static Generator IML Electrostatic Generators | |||||||

Application Material | Plastic ( ABS, PP, AS, PET, PVC ) | |||||||

Function | Adding static to plastic labels/films(IML) | |||||||

Size | 270*280*100mm | |||||||

Working Voltage | 20-30KV | |||||||

Input Voltage | 220v+10% | |||||||

Weight | 13kgs | |||||||

Warranty | 1 year | |||||||

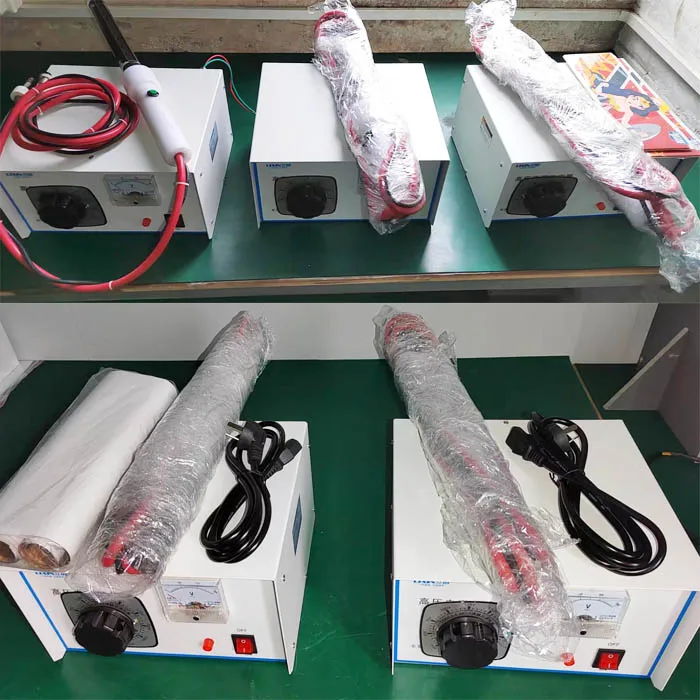

Packaging | 1 set by carton box | |||||||

Shipping | By air or international express | |||||||

Delivery Time | 2-5 work days after confirm order and make payment | |||||||

Benefit | 1.Automatic static charger for IML(in molding label) | |||||||

2.New upgrade static charger NOT old model | ||||||||

3.Help you reduce product defect rate and improve production efficiency | ||||||||

Why should we use Static generator for IML ?

Make IML more stable and comfortable.

Make 100% injection success rate!

Make 100% injection success rate!

Avoid The Following Performance:

The static charger , utilizes the electrostatic electrostatic field under the action of the electrostatic field.The characteristics of the temporary adsorption material, to achieve temporary temporary fixation of special materials. For printing.Conveying positioning for plastics processing. Adhesive blanking technology floor, glass, high-grade stainless steel,automatic lamination of plastic plates, sticker technology, in-mold film labeling, and other related fields. Pick With this product, the remarkable effect of simple process and improved efficiency can be achieved.

What is the working principle ?

The system is composed of an electrostatic generator and an electrostatic generating electrode. The electrostatic generator provides a high voltage for the electrostatic needle of the electrostatic generating electrode to generate the required charge.

The electrostatic generating electrode uses the high voltage generated by the electrostatic generator. The electric charge moves to the surface of the product under the action of the electric field.

The electrostatic generating electrode uses the high voltage generated by the electrostatic generator. The electric charge moves to the surface of the product under the action of the electric field.

Working Principle :Indirect ower-up mode

A metal plate with an antistatic material adhered to the manipulator. The manipulator sucks the label to charge the label through the static generator, and finally places it in the mold.

Working Principle: direct power-on mode

The electrostatic generator is directly installed on the robot hand. When the robot hand places the label on the mold, the electrostatic generator is controlled by PLC to power on the label, and the label will be adsorbed on the mold.

Installation Tips:

1.Far away from dirty, humid and watery and chemically corrosive environment:

2.must be placed on or under the corresponding plane,

3.Place near the machine to be installed and cable is easily connected

4.all electrostatic generators need to be well grounded

2.must be placed on or under the corresponding plane,

3.Place near the machine to be installed and cable is easily connected

4.all electrostatic generators need to be well grounded

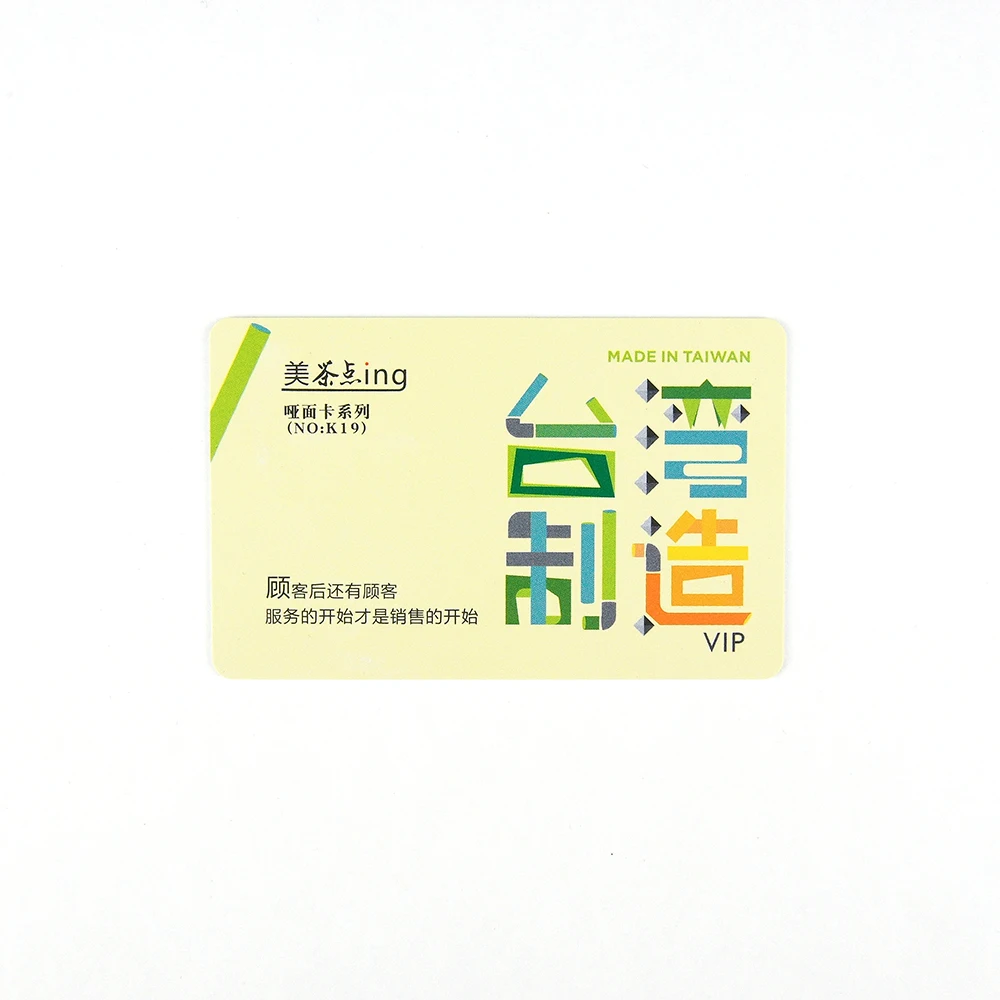

Q: What is "IML" ?

The term "in mold labeling" is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold.Then the molten PP is added to the mold. It fuses with the label, and while curing, takes the shape of the mold.

Q: What is "static charger machine "

That necessary to IML by hands printing. Make IML more stable and comfortable.

Make 100% injection success rate.

Q:Are you a manufacturer?

We are a factory integrating R & D, production and sales

Q:How big your factory?

A:10,000 square meters factory. more than 120 employees,13 sets of high speed 10 color gravure printing machine.

Q:How long of the product quality guarantee ? Do you have After-sale service system?

1 years since production date.Perfect after-sale service.any questions just feel free to ask us.

Q: What is the trading terms?

1): EXW/FOB/Shanghai or NINGBO2): MOQ: 1 set

3): Leading time: 3-5 working days

4): Payment : T/T/Western Union

5): Shipment: BY sea/Air up to customer's needs. Normal by Air/DHL/Fedex less than 100KG.

The term "in mold labeling" is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold.Then the molten PP is added to the mold. It fuses with the label, and while curing, takes the shape of the mold.

Q: What is "static charger machine "

That necessary to IML by hands printing. Make IML more stable and comfortable.

Make 100% injection success rate.

Q:Are you a manufacturer?

We are a factory integrating R & D, production and sales

Q:How big your factory?

A:10,000 square meters factory. more than 120 employees,13 sets of high speed 10 color gravure printing machine.

Q:How long of the product quality guarantee ? Do you have After-sale service system?

1 years since production date.Perfect after-sale service.any questions just feel free to ask us.

Q: What is the trading terms?

1): EXW/FOB/Shanghai or NINGBO2): MOQ: 1 set

3): Leading time: 3-5 working days

4): Payment : T/T/Western Union

5): Shipment: BY sea/Air up to customer's needs. Normal by Air/DHL/Fedex less than 100KG.

De cai Honorise New Material

MB/Wechat/Whatsapp:+0086-13456489912

best_rubberroller@aliyun.com

www.rubber-printing.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices