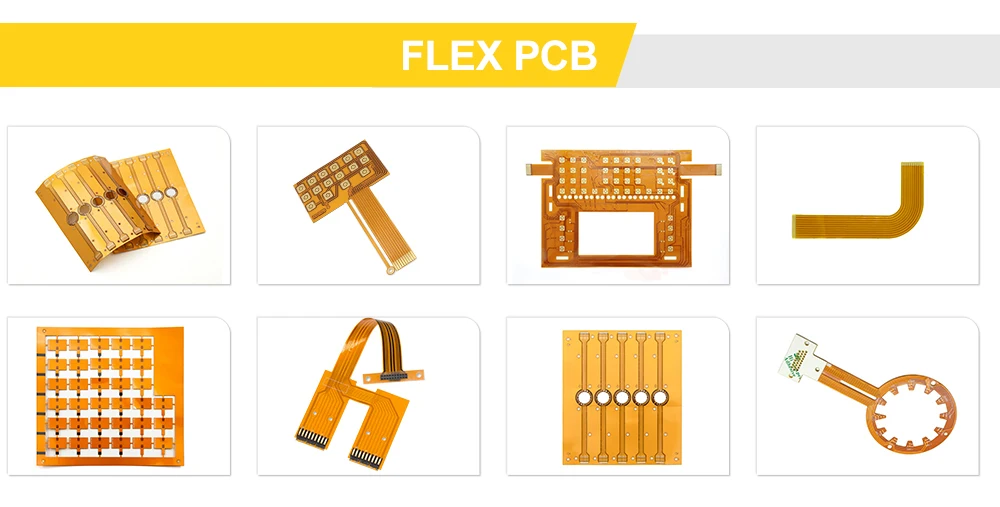

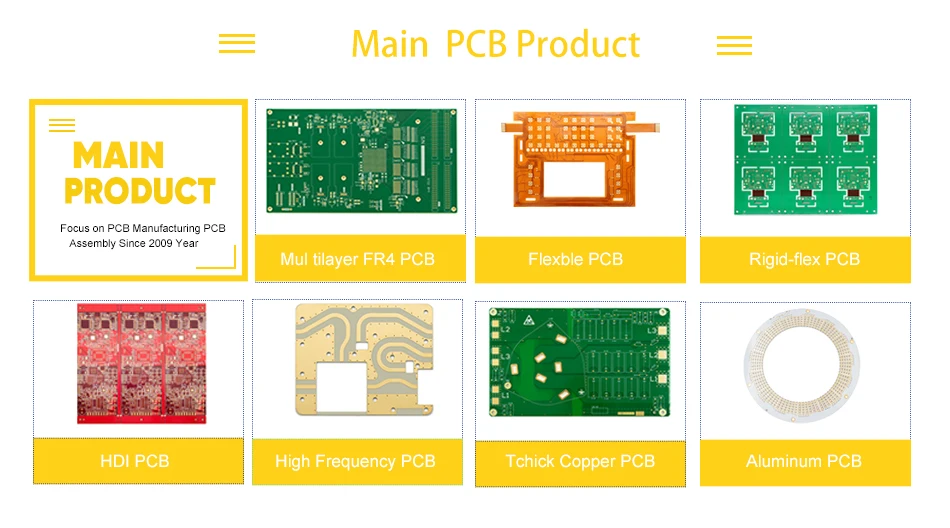

FPC Services Online Manufacturer Flexible PCB Fabrication

- Category: FPC >>>

- Supplier: Jinhua Technology (shenzhen) Co. Ltd.

Share on (1600548346077):

Product Overview

Description

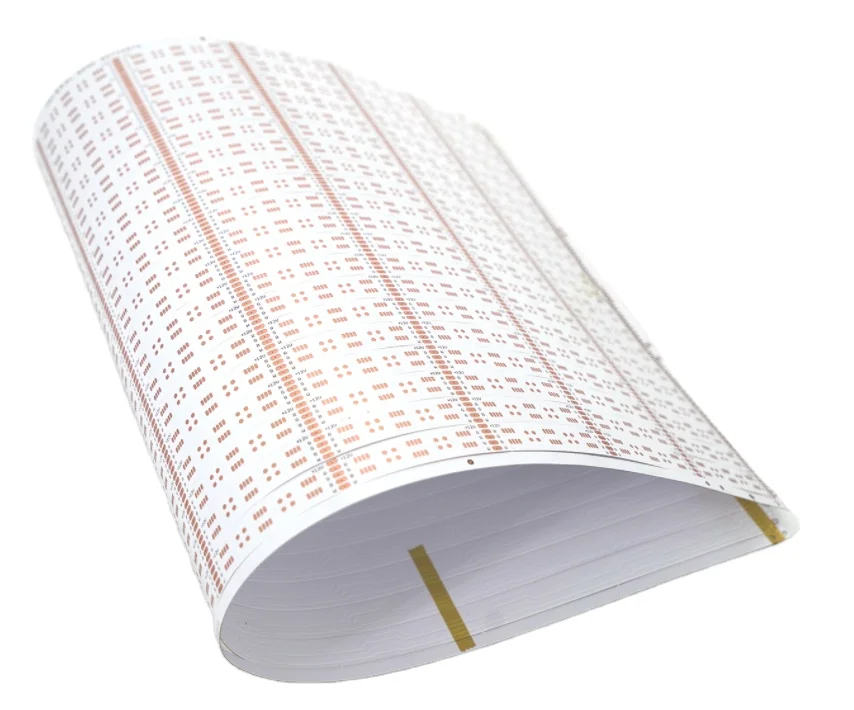

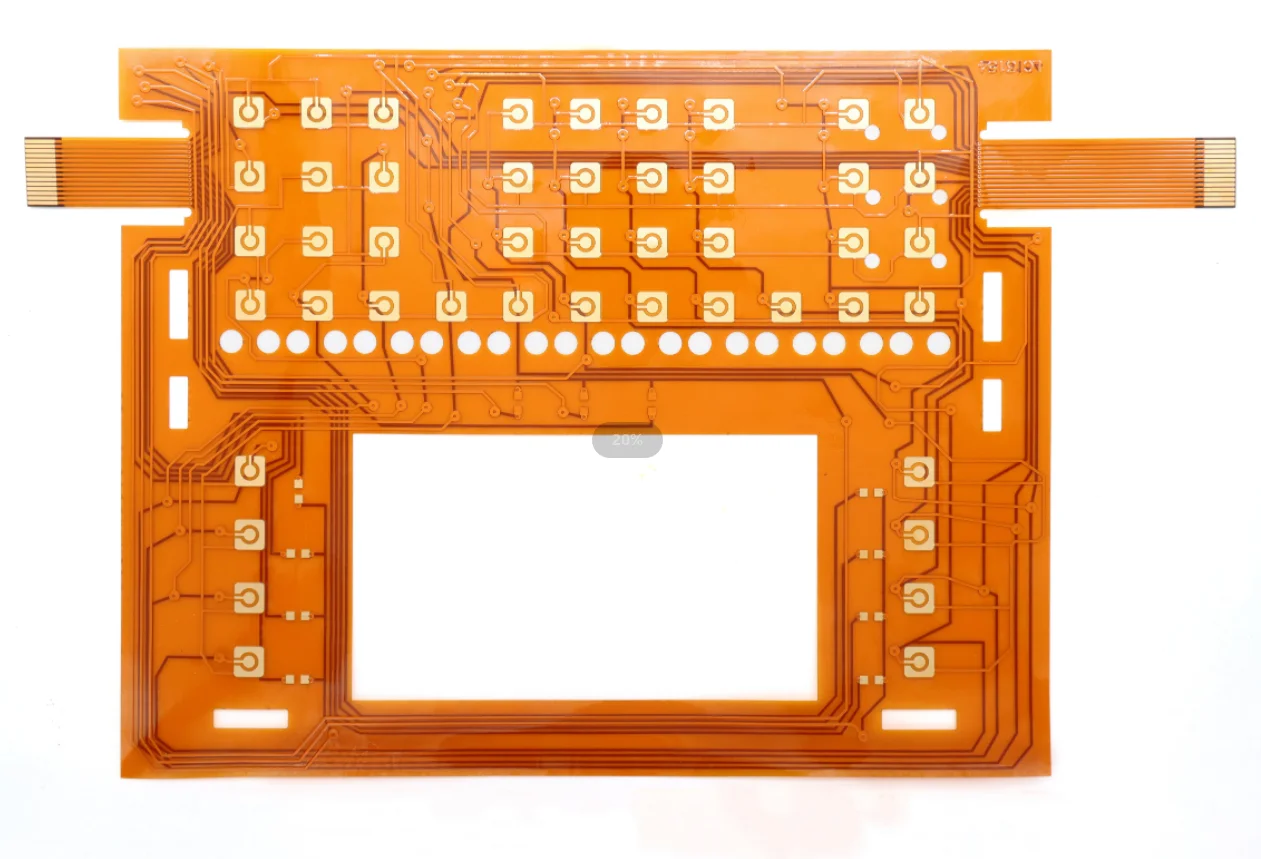

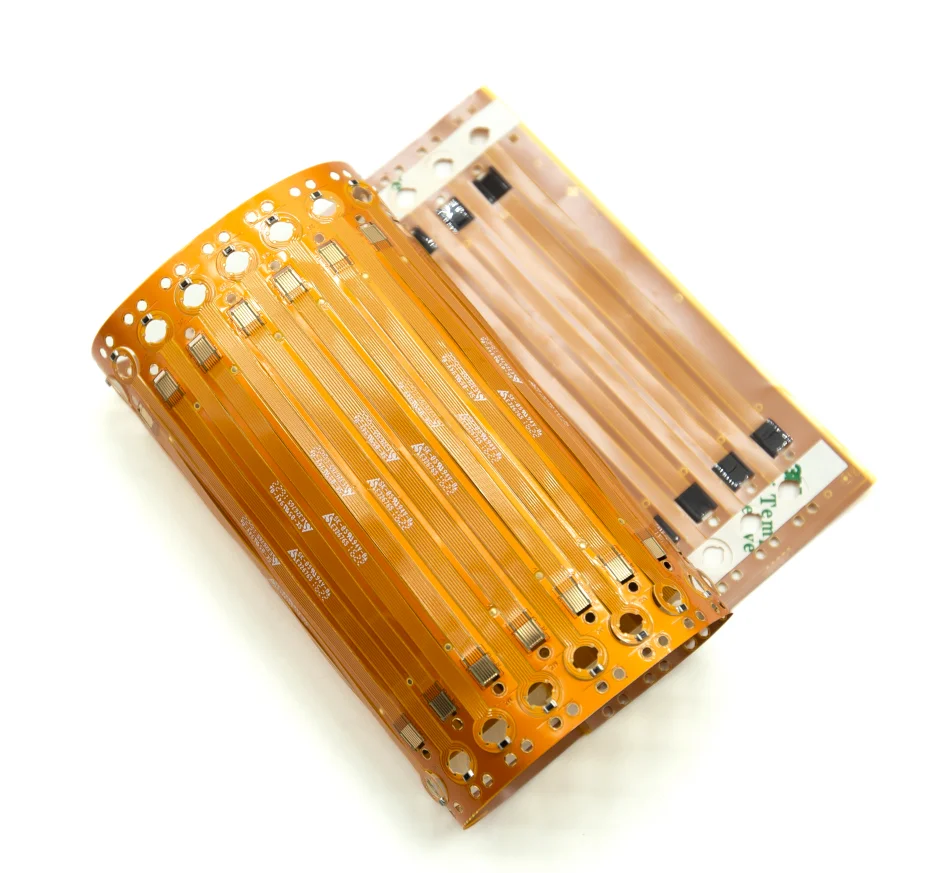

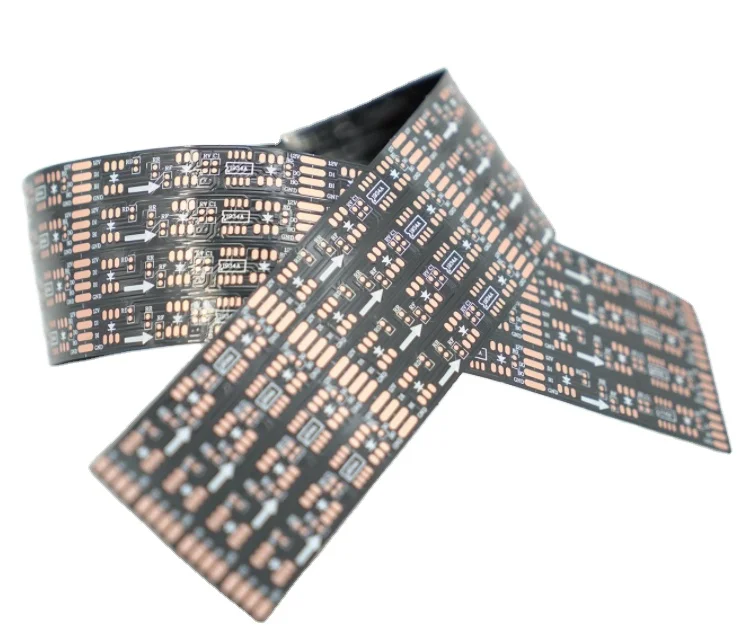

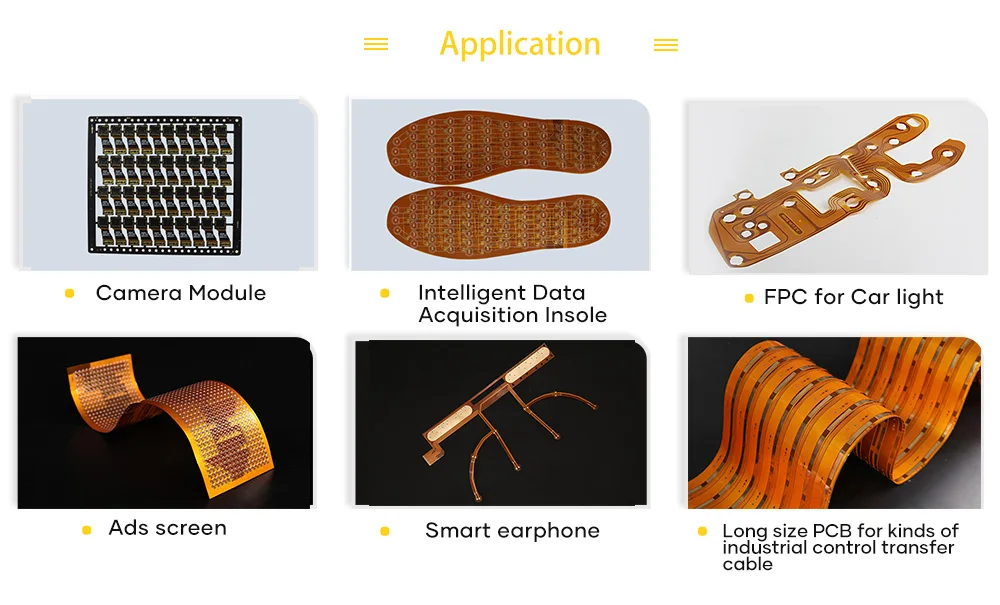

Flexible circuit boards are widely used in watches, computers, notebook computers, electronic products, cameras and other fields.

| FPC Process Capability List | ||

| Item | Content | Capability |

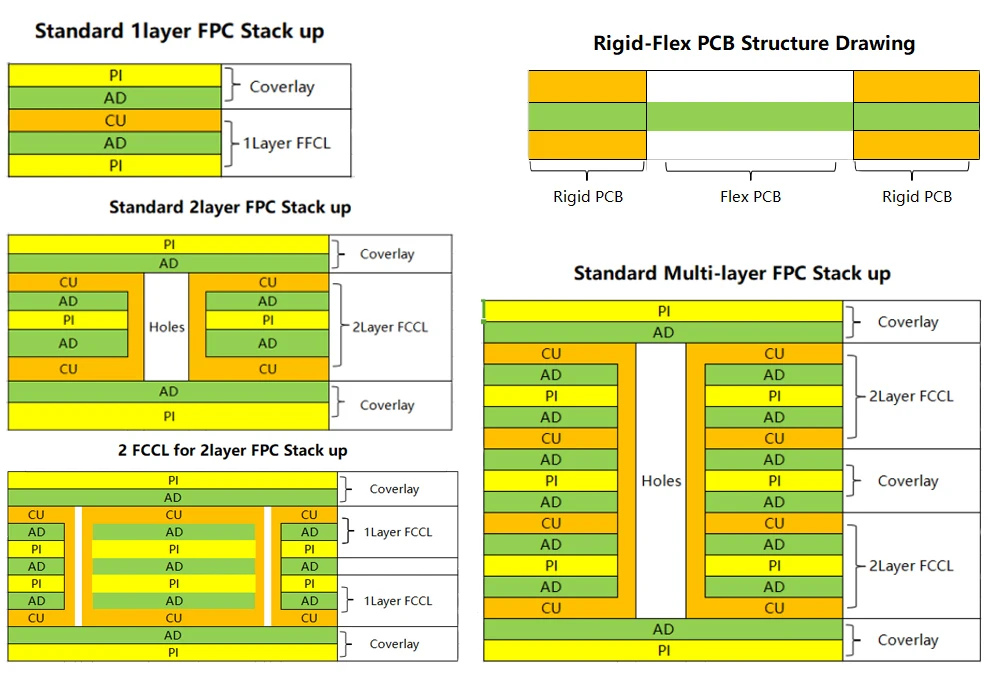

| 1 | Product type | (Single, Double/multilayer) high-density multilayer board, Rigid-Flex board, RF antenna board |

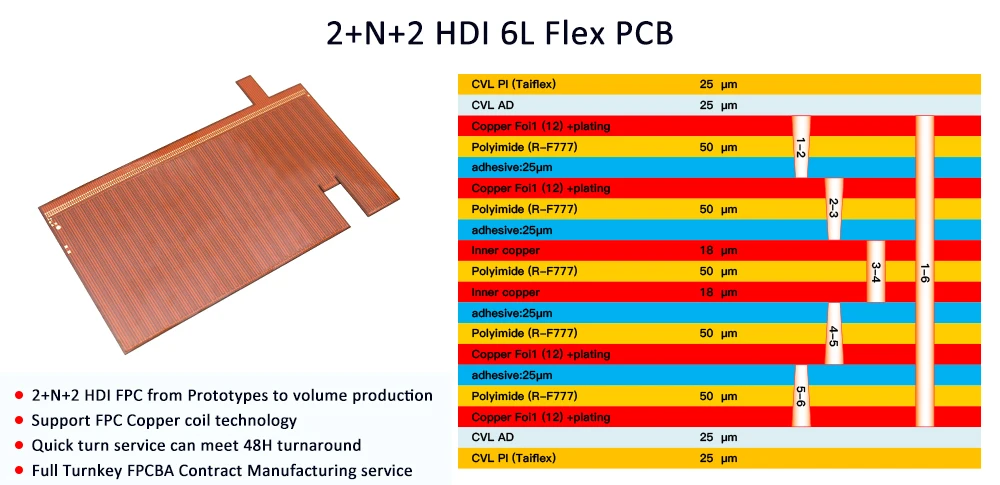

| 2 | HDI Technology | 2+N+2 |

| 3 | Layer | Flex: 1-12L; Rigid+flex: 2-20L |

| 4 | Finished board size | Min: 10*10mm; Max: 250*650mm |

| 5 | Board thickness (Min-Max) | 0.08mm-3.0mm |

| 6 | Finished product thickness tolerance | ±0.03mm |

| 7 | Copper foil thickness (Min-Max) | 1/3oz-4oz |

| 8 | Insulation thickness (Min-Max) | 0.06-3.0mm |

| 9 | CNC drill hole diameter (Min) | 0.2mm |

| 10 | Laser drill nozzle aperture (Min) | 0.1mm |

| 11 | Aperture tolerance (PTH) | ±0.075mm |

| 12 | Tolerance of drilling hole diameter(NPTH) | ±0.05mm |

| 13 | PTH Hole Wall Copper Thickness | ≥0.01mm |

| 14 | Line Width/Spacing (Min) | 0.05mm/0.05mm(1/3oz Copper foil) |

| 15 | Pad design (Min) | 0.23mm |

| 16 | Gold finger width/spacing (Min) | 0.05mm/0..05mm |

| 17 | BGA pad (Min) | 0.23mm |

| 18 | Minimum center distance between BGA pads | 0.5mm |

| 19 | Punching hole diameter tolerance | ±0.05mm |

| 20 | Via hole and via hole spacing | ≥0.1mm |

| 21 | Minimum distance from line to board edge | 0.1mm (Laser) |

| 22 | Minimum character | Character height 0.8mm/Word width0.13mm |

| 23 | Thermosetting white oil overprint tolerance | ±0.2mm |

| 24 | Etching tolerance | ±5% |

| 25 | Surface Finishing | ENIG, Electric nickel gold, OSP, HAL LF, Immersion Sliver, Immersion Tin |

| 26 | Punching shape tolerance (laser cutting) | ±0.05mm |

| 27 | Punching shape tolerance (slow-moving wire steel die) | ±0.05mm |

| 28 | Punching shape tolerance (fast-moving wire steel die) | ±0.1mm |

| 29 | Finished board impedance control | ±10% |

| 30 | Material | PI, Panasonic, DuPont, Stiffener |

Q1. What does Jinhua Tecenology can do?

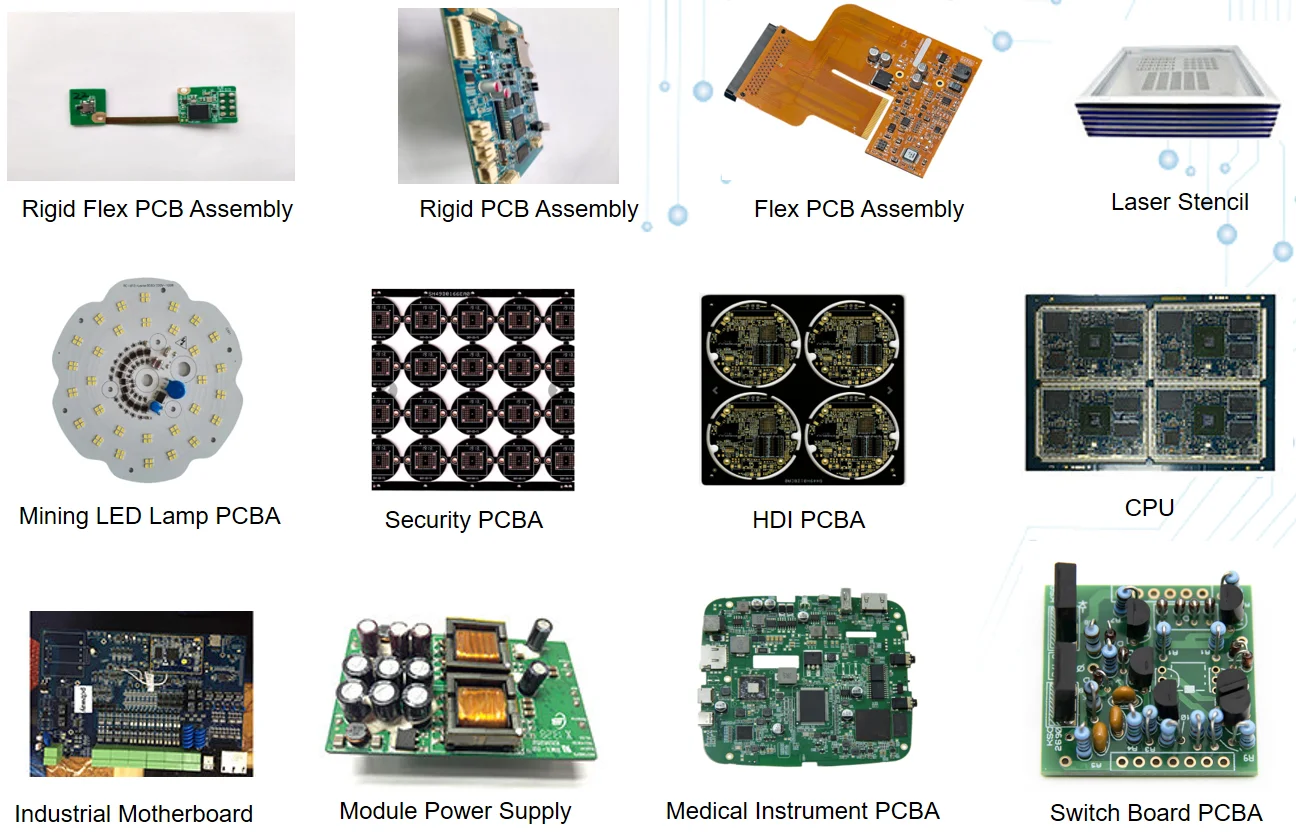

We can support you PCB Design, PCB board manufacturing, Components or Parts Source, Surface Mount (SMT), Thru-Hole (THT),hybrid of both, Functional Test, Wire Soldering etc one stop PCB&PCBA service

Q2. For PCB quotation, what files format do JINHUA need?

Gerber, Protel 99SE, DXP, PADS 9.5, AUTOCAD, CAM350 are OK.

| Bare PCB Prototype | |

| Layer | Quick Turn |

| 2 | 24 hours |

| 4 | 48 hours |

| 6-8 | 72 hours |

Q3. What will I get from you? Are my files safe?

You will get the free DFM feedback for PCB gerber files, BOM list components feedback, Quotation feedback within 2 hours. NDA can be signed for extra security issue.

Q4. MOQ?

There is no MOQ in Jinhua Tecenology. We can offer prototype, expedite prototype, small&medium amount, big amount pcb & pcba service.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices