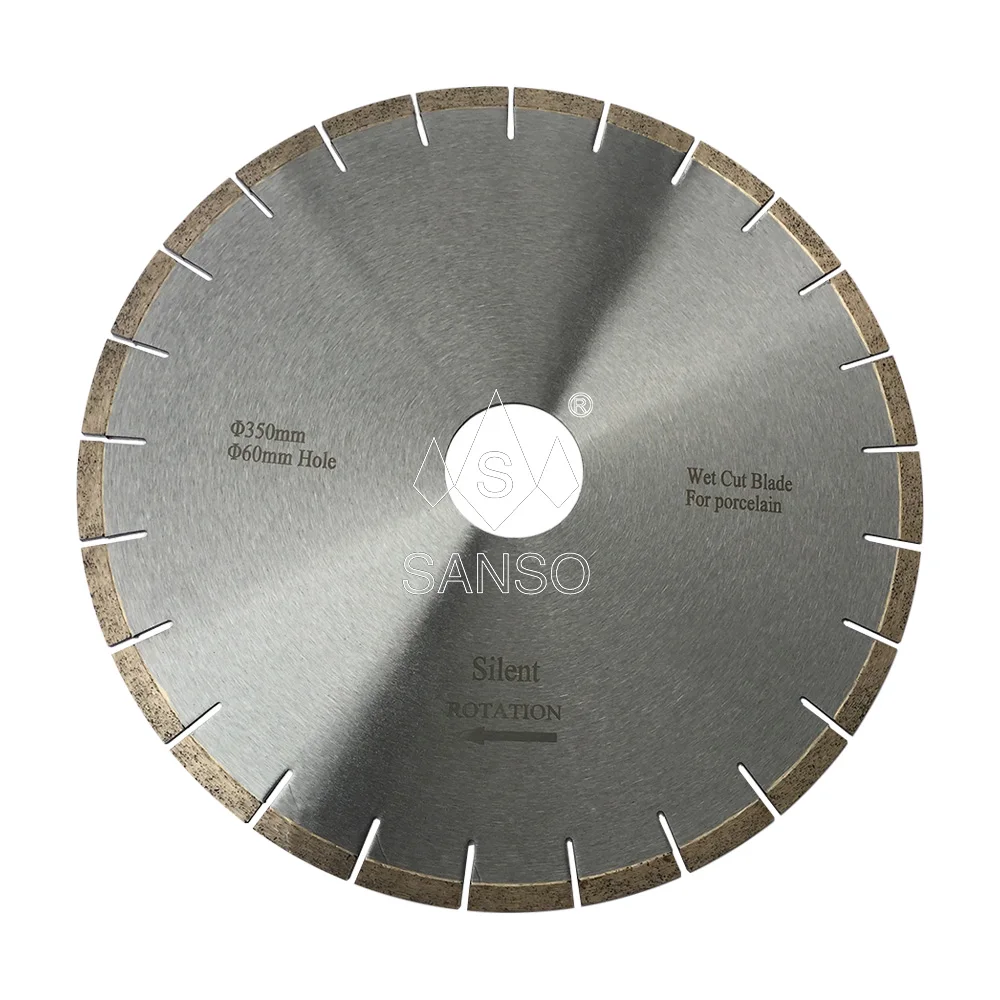

silent stone saw blade cutting disc for marble limestone ceramic Dekton

- Category: >>>

- Supplier: Quanzhou Sanso Superhard Tools Technology Co. Ltd.

Share on (1600566883304):

Product Overview

Description

Product Description | |

Product name | Diamond Cutting Blade |

Brand | Sanso or OEM |

Specification

|

1. Size:10”-100”(250mm-2500mm) 2. Segment height:8/10/12/15/20/25mm 3. Inner hole: 22.23mm/25.4mm/50mm/60mm/80mm/100mm

|

Features: |

Wet cut; Multi-application saw blades suitable for fast, free and smooth cutting.

|

Application |

Tile,bricks,brick blocks,concrete,marble,granite,stone, etc.

|

Technology | High frequency welded/Laser welded |

Quality Control: |

1. Strict Raw material inspection 2. Professional formula 3. Production process control 4. Do some cutting testing to sure the using function 5. Products pass strictly inspection

|

Payment term: | TT,western union,PayPal etc |

Package: | Plastic bag/paper bag+wooden bag or custom made |

Delivery: | 7-12 working days after receiving payment. |

How Do Diamond Blades Work?

Understanding how a diamond blade works will help you choose a blade with the right characteristics and cutting quality for your needs. Here are the four basic blade components:

·The metal core, a precision-engineered steel disk with a segmented rim that holds the diamonds.

·The synthetic diamond crystals, the sharp cutting teeth that slice through the concrete.

·The matrix, a metal bond that holds the diamond particles in place until they wear away.

·The weld, which attaches the cutting segments to the core (most segments are laser welded or soldered).

The exposed diamonds on the surface of each segment do the cutting, using abrasive action to slice through material as the blade rotates at high speeds. As the diamonds at the surface become dull through use, the matrix begins to shed away to release the worn diamond crystals and expose new, sharp diamonds embedded within the matrix.

The most important fact to know is that the hardness of the matrix controls how quickly a blade wears.

Here's the basic rule:

A diamond blade used to cut soft, abrasive materials (such as uncured, green concrete) should have a hard metal bond so the exposed diamonds are fully utilized before they shed away. Conversely, a blade for cutting hard, nonabrasive concrete should have a soft bond to allow for easier erosion of the matrix, which will ensure exposure of new, sharp diamonds when you need them.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices