China ISO9001 Powerful Durable 800T Power Press Machine Automobile Application Stamping Die

- Category: >>>

- Supplier: Qingdao Hiparter Metal & Plastic Products Co. Ltd.Qingdao Ltd.

Share on (1600568533128):

Product Overview

Description

Company Profile

Qingdao Hiparter Metal&Plastic Products Co., Ltd.

Established in 2003, in Qingdao, China, a professional stamping die manufacturer.

Committed to stage stamping dies and progressive stamping dies.

Products Description

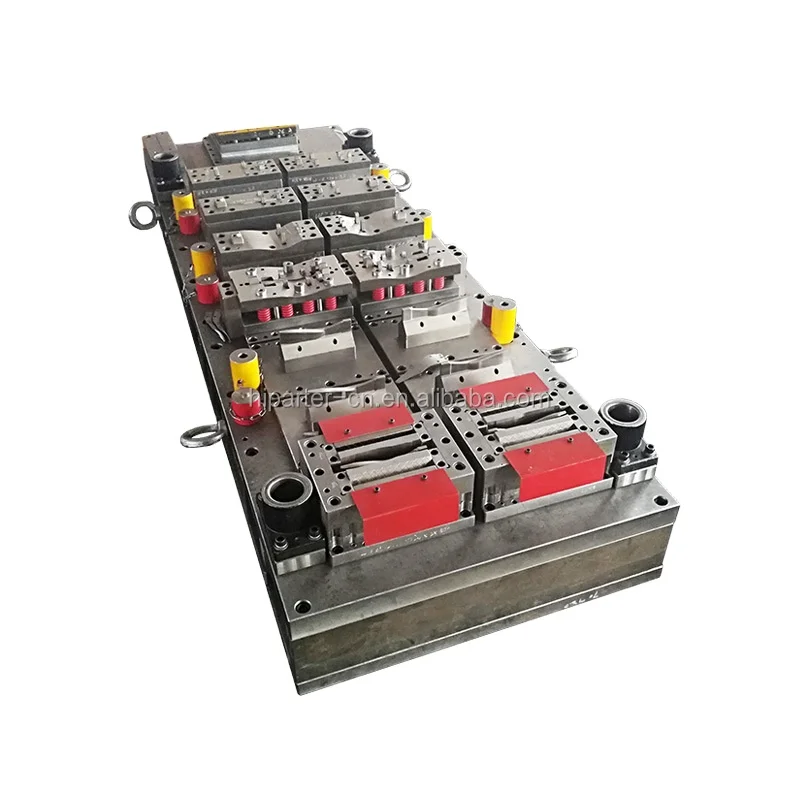

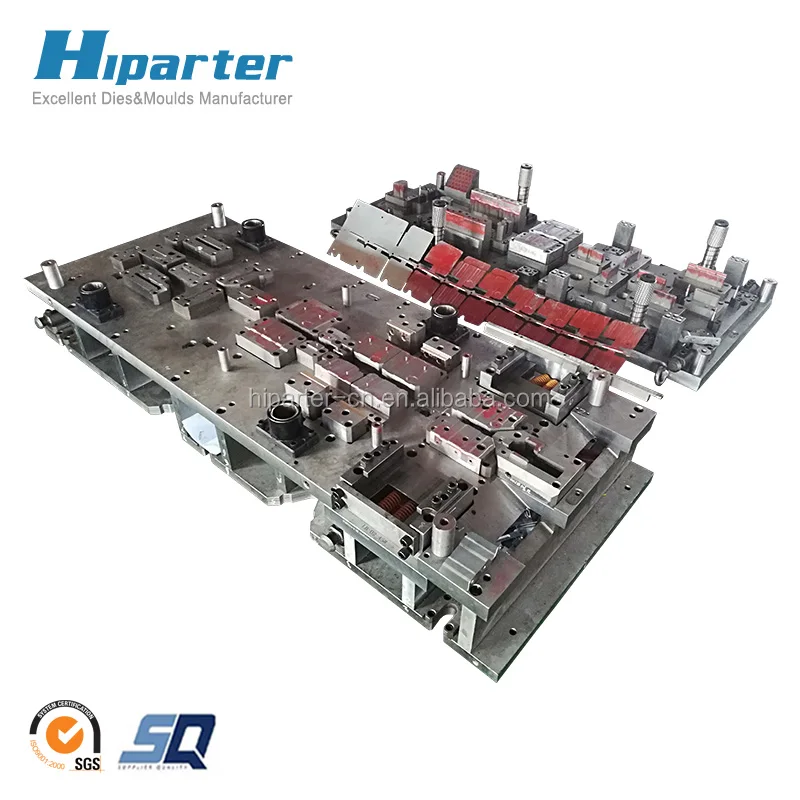

800T Power Press Machine Automobile Application Stamping Die

Custom stamping dies, provide design and manufacturing service.

800T Power Press Machine Automobile Application Stamping Die

Insists on providing high-standard and high-quality stamping dies and support.

Qingdao Hiparter Metal&Plastic Products Co., Ltd.

Die Type | Progressive Stamping Die, Stage Stamping Die, Transfer Stamping Die | ||||

Die Material | SKH-9, DC53, SKD11, Cr12Mov, Cr12, 45# | ||||

Product Material | Cold steel, Galvanized steel, Stainless steel, etc. | ||||

Standard Part | MISUMI, PUNCH, FIBRO, DAYTON, DME, etc. | ||||

Manufacturing Machinery | Milling, Grinding, Boring, CNC, EDM, WEDM, Precision Milling, Saw Machine | ||||

Press Machinery | 45T~800T, Power Press, Hydraulic Press | ||||

Inspection Machinery | CMM, Vision Projector, Micro-Callipers, Laser Scanner, Alloy Analyzer | ||||

Lead Time | 6 weeks for die buidling, after the die structure drawing confirmed. | ||||

Rich experience in stage stamping die, progressive stamping die and transfer stamping die.

Stage Stamping Die

Progressive Stamping Die

Transfer Stamping Die

Related Products

Sheet Metal Stamping Part

High Quality Stamping Die

Thin Metal Stamping Part

Our Advantages

1. Stamping Die

Design Capacity

1)We adhere to total solution service:

product design optimization→ stamping die design→ stamping die manufacturing→ stamping die debugging→ product inspection→ die specification manual sharing→ after-sales support.

2)3D and CAD/CAM/CAE design

3)More than 10 stamping die design engineers

2. Stamping Die Manufacturing Capacity

1)Machining equipment more than 28 sets

2)Slow speed wire cutting machine and middle speed wire cutting machine more than 11 sets

3)Fully equipped with grinding, milling, drilling, NC, wire cutting machine, etc.

4)Almost all the machining process completed in-house.

3. Stamping Die

Production Capacity

1)45T~800T press more than 24 sets, Power Press and hydraulic Press

3)Material feeder for progressive die 8 sets

4)Experienced technology engineers and well trained workers

5)Almost all the stamping die trial completed in-house.

4. Stamping Die

Quality Control Capacity

1)Inspection: CMM, projector, 3D Scanner, Blue scanner, White scanner, Alloy analyzer, etc.

3)Inspection report for stamping dies and stamping parts

2)CMM inspection for precision components

4)To control the quality of the stamping dies, we have a strict quality control mechanisms.

5. Stamping Die

Delivery Control Capacity

1)2~6 weeks lead time

2)Update stamping die building progress weekly, ensure project schedule

3)Exported to over 30 counties

4)With more than 10 years of import and export experience

Packing & Delivery

Vacuum Packing

1.Rich experience in exporting, reasonable packaging to reduce the shipping risk.

2.For the packaging, the stamping dies are vacuum packed in aluminum film bag first, then fastened by metal packing tape, and finally packed in wooden cases.

3.We surely can make the packing following customers' requirement.

3.We surely can make the packing following customers' requirement.

Our Service

One-Stop Service

1. Experienced engineer group

2. Skilled masters3. Quality control in house, from design to delivery, one entire system

4. Pursue of high quality, high precision

5. Lowest cost for customer

6. Excellent service, represented in each Hiparter member

Contact US

If you want to get more information about Hiparter or stamping dies, please feel free to contact us as below.

Email: project@hiparter.com

We will feedback to you within 24 hours.

We will feedback to you within 24 hours.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices