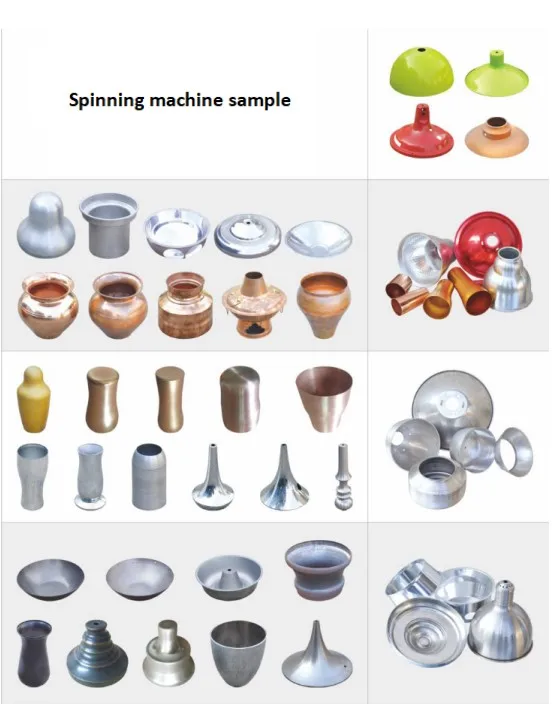

Spinning Lathe Machine For Stainless Steel Plate Bowl Cone Pan Spinning

- Category: >>>

- Supplier: Shanghai Nansen Industry Co. Ltd.

Share on (1600571019424):

Product Overview

Description

Spinning Lathe Machine For Stainless Steel Plate Bowl Cone Pan Spinning

Make the Aluminum Kettle for spinning meanwhile.

The machine is high automatic speed , high-efficiency Install Spinning mould .

We are engaged in presenting a high-class range of Cutting Trimming And Beading Machine.

Experience, which exalts our great flexibility in providing trimming solutions, as well as a technological service focussed on seeking the most useful result for the customer in terms of greater productivity and cost-saving production.

| Main Motor Power | 3kw |

| Cutter head motor power | 1.1kw |

| Rotate speed of main shaft | 1800 times /minutes |

| Rotate speed of cutter head | 8r/m |

| Height of saddle mouth | 800mm |

| Length of saddle mouth | 480mm |

| Machine external dimension | 2000*1500*1500cm |

| Weight | 2500kg |

| Spinning material | carbon steel, stainless steel,aluminum and copper, etc. |

| Function | Spinning, trimming, crimping |

Our product range consists of Deep Draw Press Machine, Press Machine, Cutting Machine, Punching machine ,Polishing machine Forming Machine etc. Our whole range is precisely designed under the guidance of an experienced team of professionals. We are offering our products at a normal market price. Along with these products, we are also offering after sales services to our valued clients.

We are also supported by a team of highly experienced and skilled professionals which enable us to manufacture the offered products as per the industry approved parameters. To assure it, each product is strictly manufactured by following the suggestions given by our R & D team and further stringently checked in our quality-testing unit.

This machine is suitable for the drawing and especially deep drawing of thin plate material on account if the greater die distance and the moving operating platform ,it features stable and smooth bottom drive and double action ,compact structure ,low center of gravity and low noise.

From Shanghai NANSEN-SUB Machinery Manufacturing Co.,Ltd,established in 1976,is situated in JS Province,Nearly Shanghai City.area of 16,000 square meters, hs currently hired 120 employees, 20 engineers and technicians included, as professional in mechanical manufacturing and processing. The manufacturing of the company is ZF NANSEN machine ..Quality is our sole enterprise ..We are manufacture deep drawing press machine ,Spinning machine , Trimming beading machine,punching machine,Polishing machine, Rivet machine, & relative cookware industry Punching press machines technology-service .

The machine is mainly used for enamel, aluminum utensils, stainless steel utensils, and a variety of daily hardware, household appliances, instrumentation, cars, tractors, agricultural machinery and other parts of the stretch processing, with a wide using range.

Mechanical Double Action Deep Drawing machine Advantage are,

1).Mechanical is save power which is under mechanical system of inertial System for working which is very save power.

2).Machine working noise is very lower.

3).Maintain costing is very lower in the future.

4).Keep Using time more Years at least depend on Generally Working.

5).Speed is fast ,13-15 Pcs/Minutes

6).Operate working is very easy for workshop.

7). ELEC. 415V/50HZ/3PHASE is enough.

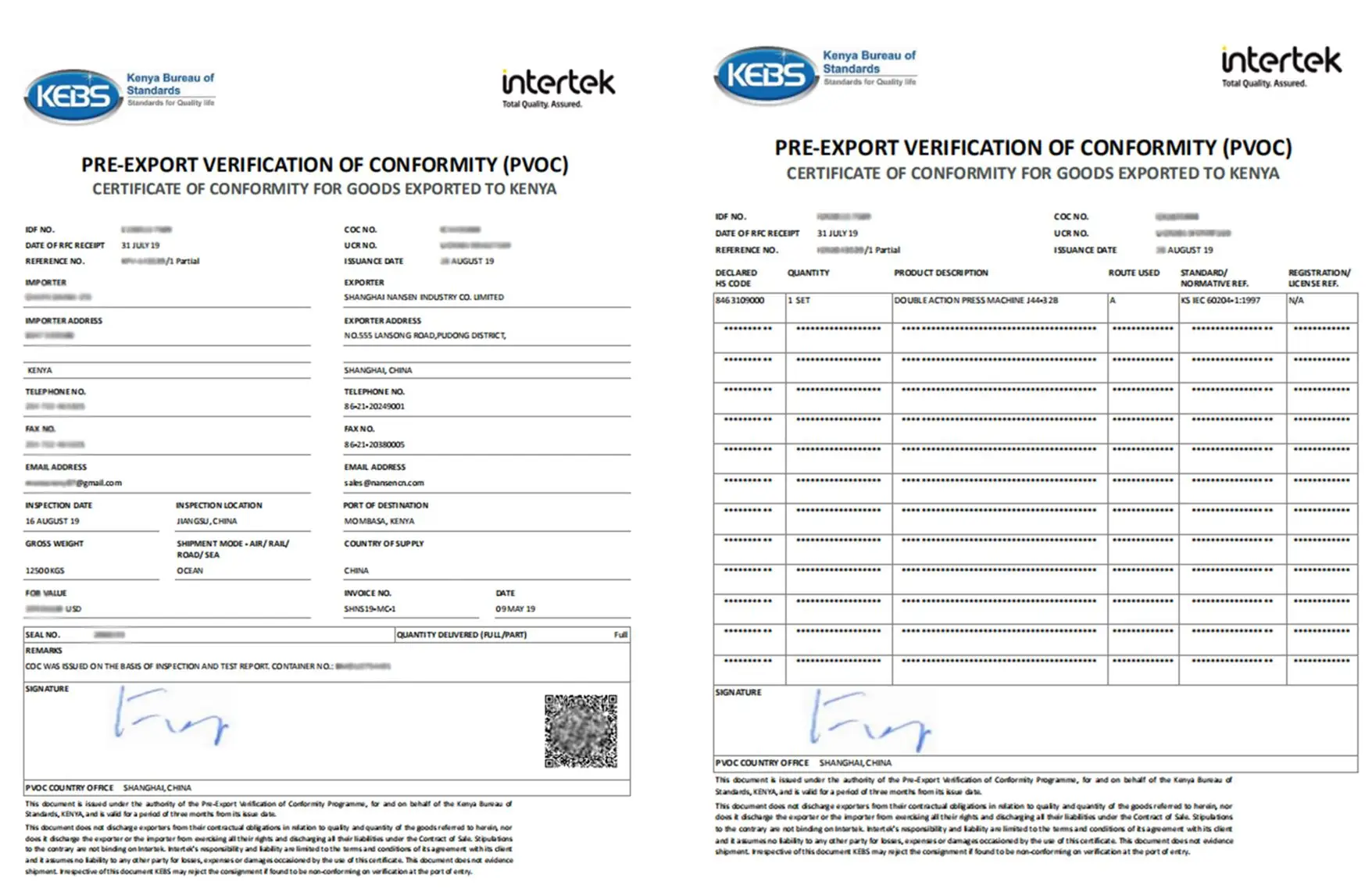

8). Had approved intertek certificated as Standard (COC,certificate of conformity):IEC60204-1

Ms. Monica

Shanghai Nansen Industry Co., Ltd.

Address: Pudong District, Shanghai, China.

Tel: 86-21-2024 9001

Wechat /what'app : 0086-182 0211 2981

Email: sales at nansencn. com

Website: www.nansen-machine.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices