Автоматическая машина для производства пружинной шайбы диаметром 0,2 6 мм, машина для производства пружинной проволоки

- Category: >>>

- Supplier: Zhejiang Yinfeng Automotion Technology Co. Ltd.

Share on (1600599063650):

Product Overview

Description

Products Description

Product advantages 1

The crimp function has a detachable installation function, which has a faster processing speed for corner processing and arc bending. The function of the wire transfer system solves the problem that the entire wire feed of the spring machine can be rotated 360 degrees in the forward and reverse directions during the wire feed process.

Multiple angle forming and cutting, also improve the working efficiency of the machine, more convenient debugging, simpler forming, more convenient operation, more powerful functions. Suitable for the production of double torsion springs, straight springs, pagoda springs, tension springs, Rectangular spring wire forming, steel skin vortex spring, spring and various fancy springs, complicated and difficult shaped springs, etc.

Multiple angle forming and cutting, also improve the working efficiency of the machine, more convenient debugging, simpler forming, more convenient operation, more powerful functions. Suitable for the production of double torsion springs, straight springs, pagoda springs, tension springs, Rectangular spring wire forming, steel skin vortex spring, spring and various fancy springs, complicated and difficult shaped springs, etc.

Product advantages 2

YF Brand CNC spring machine concentrated have unique increase stroke, specially processed complex shape of the spring unique tuner-core structure, never relaxed, no maintenance, unique integrated feed line structure, Japan servo motor and Taiwan CNC control system ensure the accuracy of the wire feed to meet the demanding requirements, production good quality spring.

Product advantages 2

1. A precious inspection tracer device is installed, it will stop working automatically When the unqualified product is found.

2.The parameters such as major diameter, angle etc can be modified at any time according to the working status displayed on the fluorescence screen.

3.It is suitable for producing double torsion spring, straight spring, pagoda- -shaped compression spring, rectangle spring,swirl spring and other different spring and special-shaped spring etc.

2.The parameters such as major diameter, angle etc can be modified at any time according to the working status displayed on the fluorescence screen.

3.It is suitable for producing double torsion spring, straight spring, pagoda- -shaped compression spring, rectangle spring,swirl spring and other different spring and special-shaped spring etc.

Automatic material feed frame

1.Characteristics: timing, disconnection, (starved feeding), abnormal stops (deviation), automatic alarm stop run, induction

2.control, high safety control compatibility, can use for parallel or serial electric production machinery, to independent or

3.synchronization feeding material.Automatic material feed frame YF-150 -350-500-1000(weight bearing between 150-1000 Kg)

2.control, high safety control compatibility, can use for parallel or serial electric production machinery, to independent or

3.synchronization feeding material.Automatic material feed frame YF-150 -350-500-1000(weight bearing between 150-1000 Kg)

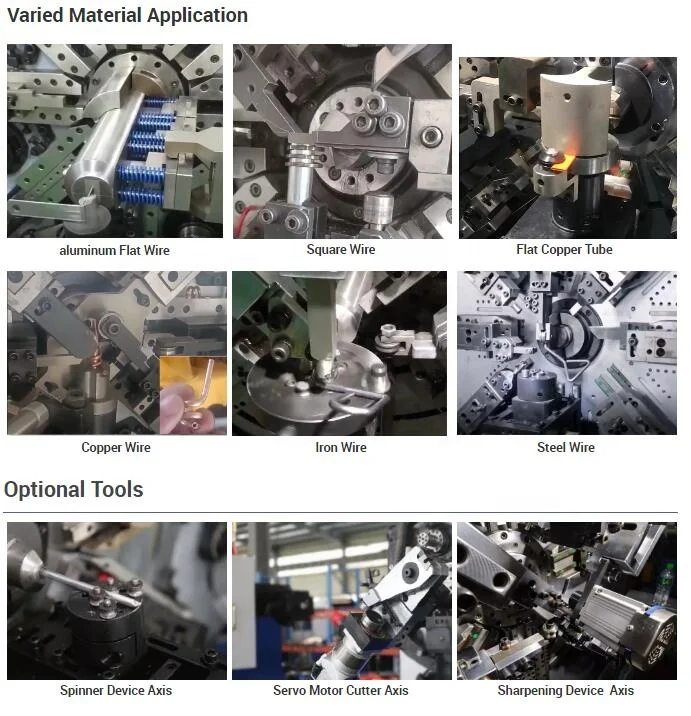

Varied Material Application

aluminum Flat Wire

Square Wire

Flat Copper Tube

Copper Wire

Iron Wire

Steel Wire

Optional Tools

Spinner Device Axis

Servo Motor Cutter Axis

Sharpening Device Axis

Our Yinfeng Machine Can Make Any Kinds Of Spring, Also We Can Customized Extra Function According To Your Requirements.

Manufacturing Product Videos

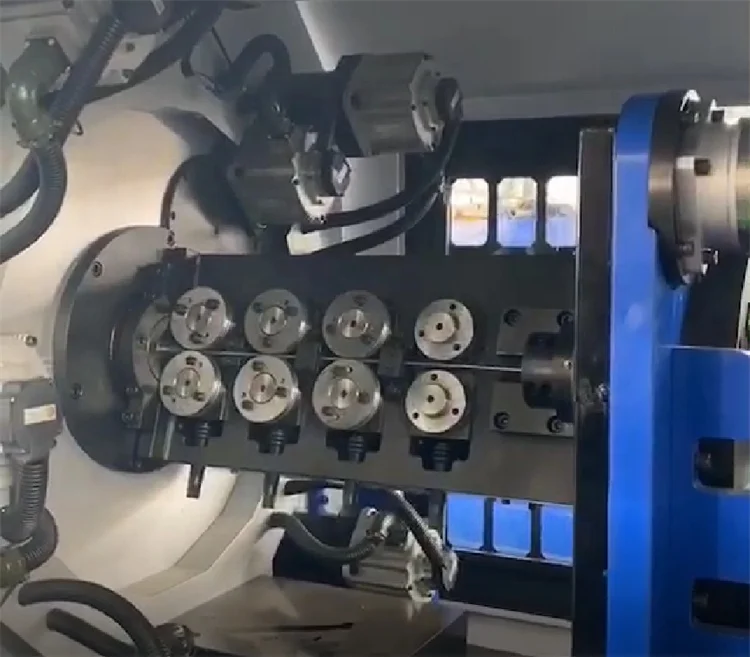

Product Paramenters

Wire diameter of coiled material | Φ1.5-Φ4.5mm(iron wire Φ1.5-Φ6.0mm) | Cam servo motor | 5.5KW |

Max outer diameter of coiled spring | Max0110mm | Core-switching servo motor | 1.5KW |

Wire Feed instruction value | ±0.01-±9999.99 | Wire-switching servo motor | 2.9KW |

Max Wire Feed speed | 0-80m/min | Spinner axis servo motor | 1.0KW |

Cam instruction value | ±0.1°- ±359.9° | Power supply | 380V ± 10%V50HZ |

Cam rotation speed | 1-60RPM | Size | 1800x1700x2100mm |

Wire feed servo power | 5.5KW | Weight | 3800KG |

Price list could be sent upon request, just kindly contact us:

Ms Grace Email: yinfengspring@163.com Cell/Whatsapp:+8618520279887

Ms Grace Email: yinfengspring@163.com Cell/Whatsapp:+8618520279887

Why Choose Us

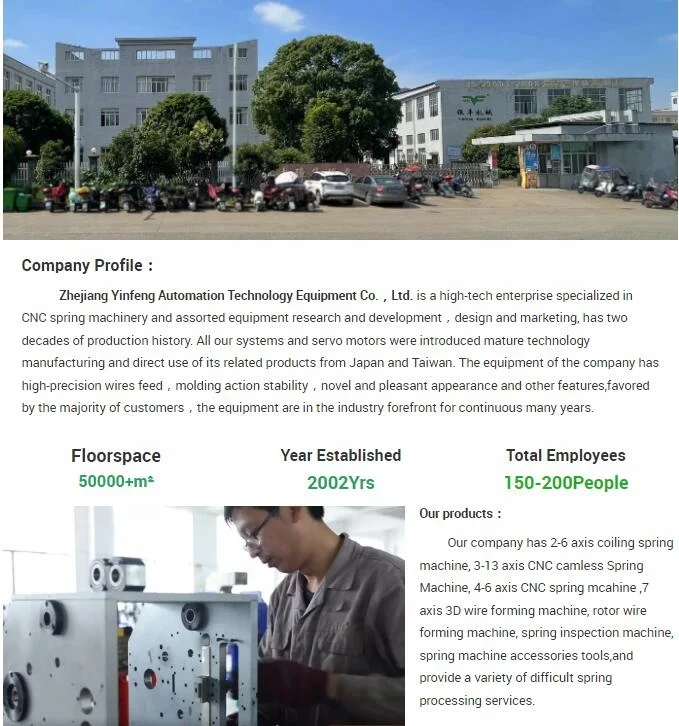

Company Profile:

Zhejiang Yinfeng Automation Technology Equipment Co.,Ltd. is a high-tech enterprise specialized in CNC spring machinery and assorted equipment research and development,design and marketing, has two decades of production history. All our systems and servo motors were introduced mature technology manufacturing and direct use of its related products from Japan and Taiwan. The equipment of the company has high-precision wires feed,molding action stability,novel and pleasant appearance and other features,favored by the majority of customers,the equipment are in the industry forefront for continuous many years.

Floorspace

50000+m²

Year Established

2002Yrs

Total Employees

150-200People

Our products:

Our company has 2-6 axis coiling spring machine, 3-13 axis CNC camless Spring Machine, 4-6 axis CNC spring mcahine ,7 axis 3D wire forming machine, rotor wire forming machine, spring inspection machine, spring machine accessories tools,and provide a variety of difficult spring processing services.

Our equipment can produce:

Our equipment can produce pressure springs, tension springs, torsion springs, screw sleeves and wire forming products to meet the needs of a variety of industries, including electronics, toys, electrical appliances, sports equipment, automobiles,stationery, instruments, meters, hair accessories, All kinds of high-precision springs required for crafts, etc., can also produce sheet shrapnel and winder of different specifications. In the increasingly competitive market in the future, the company will, as always, adhere to the tenet of' 'Technology first, quality win, service intimacy", “exploitation and innovation, pursuit of excellence" , providing customers in the spring industry with qualified equipment which have stable quality and reasonable price.

Finished product workshop

Stock Machines: 20-30/pcs Per Model

Total Stock:300pcs+ Monthly

Assembly Morkshop

World Standard Production Procedure Ensure High Quality and High Precision of Products

Five Assembly Workshops, each 5000 Square Meter

Customize Cut Mold

Engineers:20+

Customized Different Cut Molds According to Requirements 5 Days Lead Time for Customized Cut Mold

We Can OEM Custom According To Your Requirement

To manufacturing and servicing spring machinery meet customer demandfor quality technology, take on spring manufacturing industry partner, we all willcontinue to develop more sophisticated machinery, and to provide moreconvenient and efficient technical advice and perfect after-sales service.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory, we have been in this industry for over 20 years.

Q: How long is your delivery time?

A: Generally it is 5-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=10000USD, 50% T/T in advance ,balance before shipment.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices