High productive wet feather dewater press of animal waste rendering plant

- Category: >>>

- Supplier: Hebei Chengzhu Machinery Group Co. Ltd.

Share on (1600616238862):

Product Overview

Description

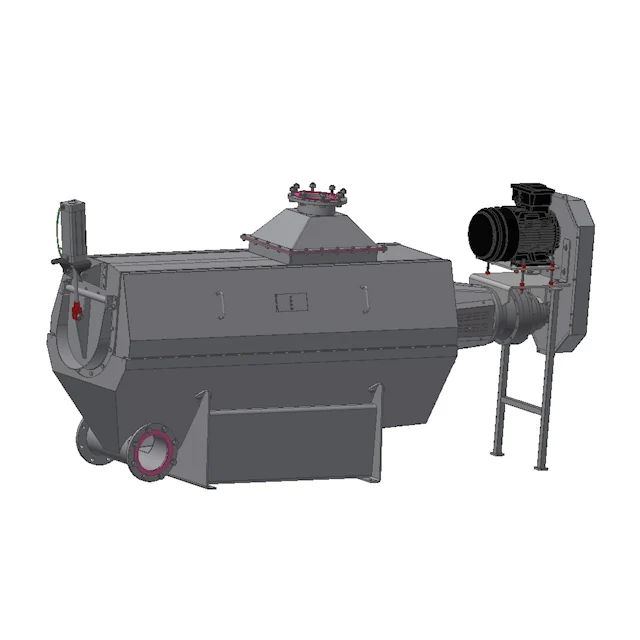

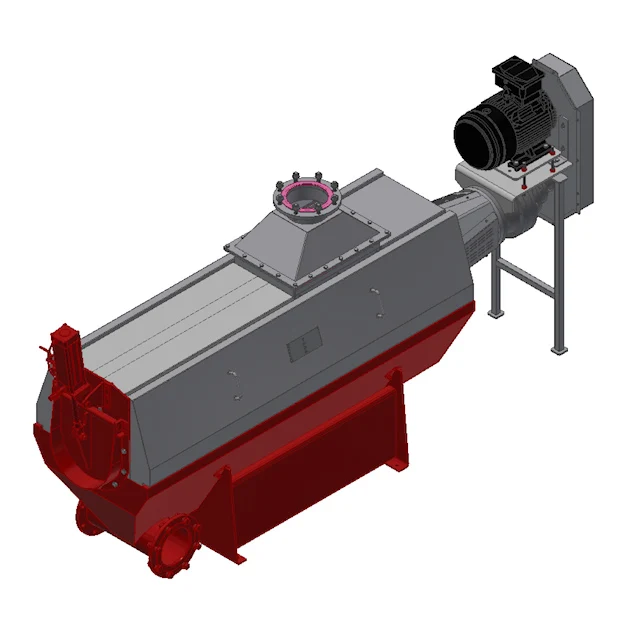

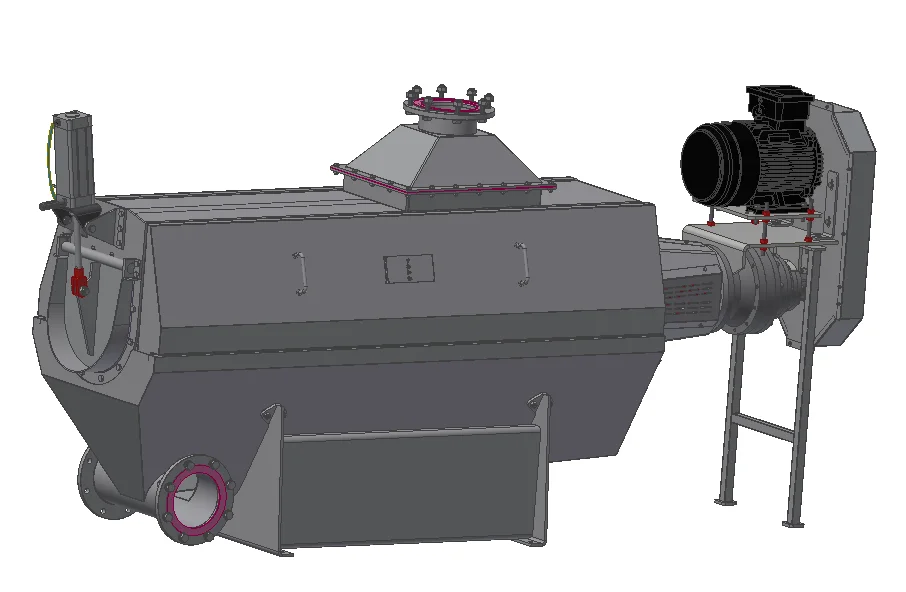

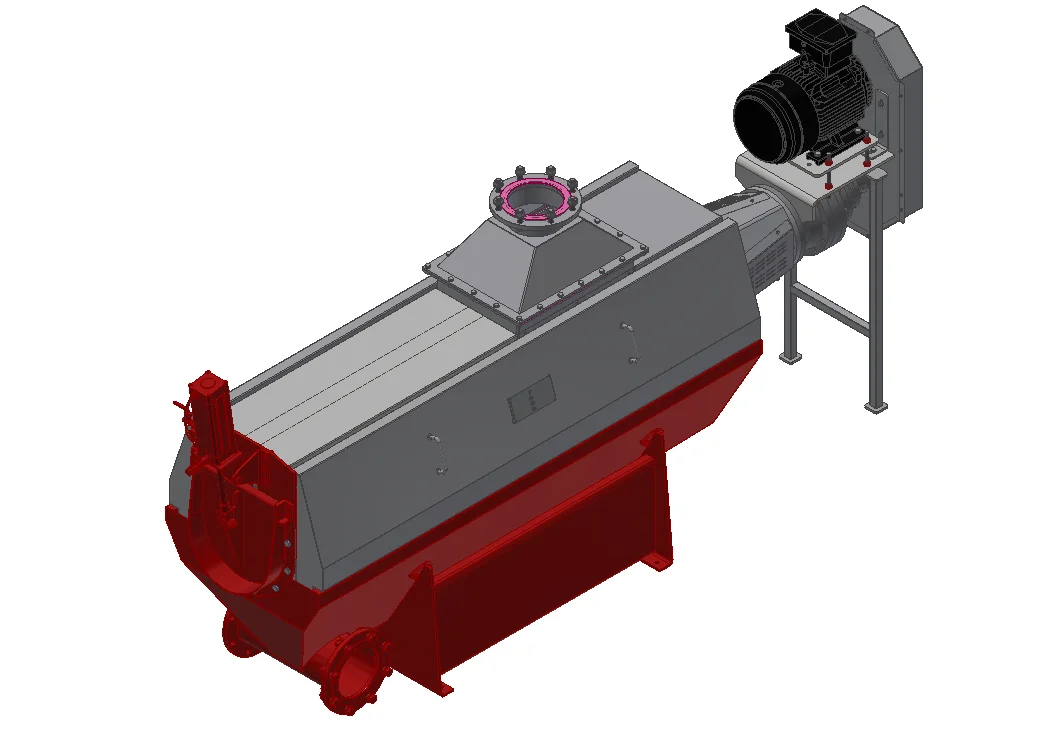

FEATHER PRESS

Modern poultry processing operations often use large quantities of water to remove the feathers once plucked or rubbed off. The sturdy Feather Press effectively removes water from chicken, goose and turkey feathers, enabling you to achieve a consistent 55% moisture level..

our feather presses can be installed downstream from a normal feather separator in a slaughterhouse, or can receive feathers plus their transport water straight from a slaughterhouse pumping system. This type of press normally removes about 350 liters of water per 1,000 kg of wet feathers from the feather separator .

Feather presses provide significant paybacks in the form of energy savings (in rendering operations) and lower transportation and feather removal costs, simply because the feathers weigh much less once the water has been removed.

1.FEATHER press

- This is a reliable, cost-effective way to dry the large quantities of feathers resulting from chicken, goose and turkey processing operations.

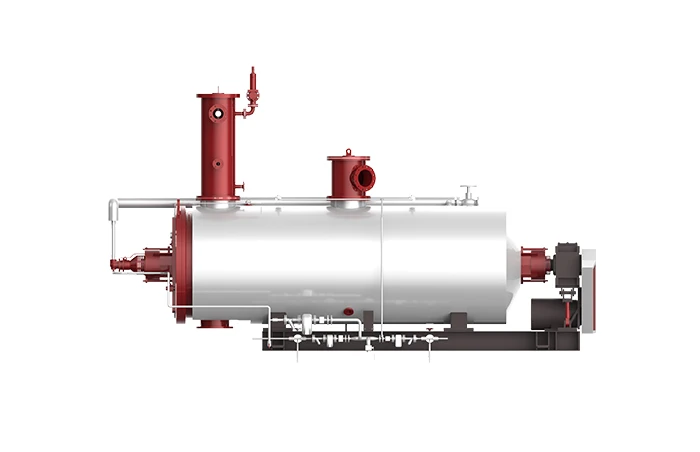

2. Cooking machine

Sequencing batch digester is a kind of cooking equipment that takes into account sterilization, hydrolysis and drying. Fuction:It is mainly used to sterilize, hydrolyze and dry animal by-products such as mixed meat viscera and aggregates, raw blood, wet feathers and mixed poultry viscera. Features:The machine is compact in design and simple in installation, and can meet the processing requirements of various materials. |

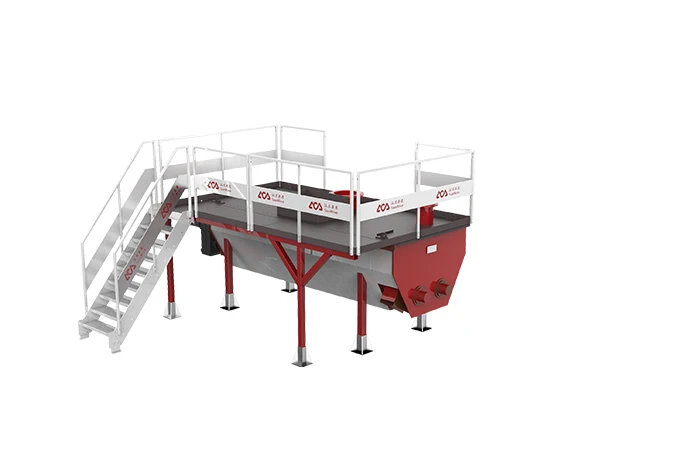

3. Receiving bin

Fuction:

For temporarily storing the materials discharged from the cooking and drying tank,And the materials are conveyed to the filter screen screw conveyor through the screw conveyor at the bottom of the receiving box.

Features:

1.The reverse spiral design is adopted and the closed structure is used at both ends of the blade,there will be no material accumulation and the conveying accuracy and efficiency will be improved.

2.The steam jacket and insulation layer are designed at the bottom of the receiving bin to maintain the temperature of the materials therein and avoid the solidification of the materials due to the temperature reduction.

4.Packing section

Automatic paking the meal

5. Odor treatment section

To seperate solids and liquids entrained in the process vapoures from cooking/drying equipment, by washing of gasses collected from several process points.

If you need the above equipment, please contact us.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices