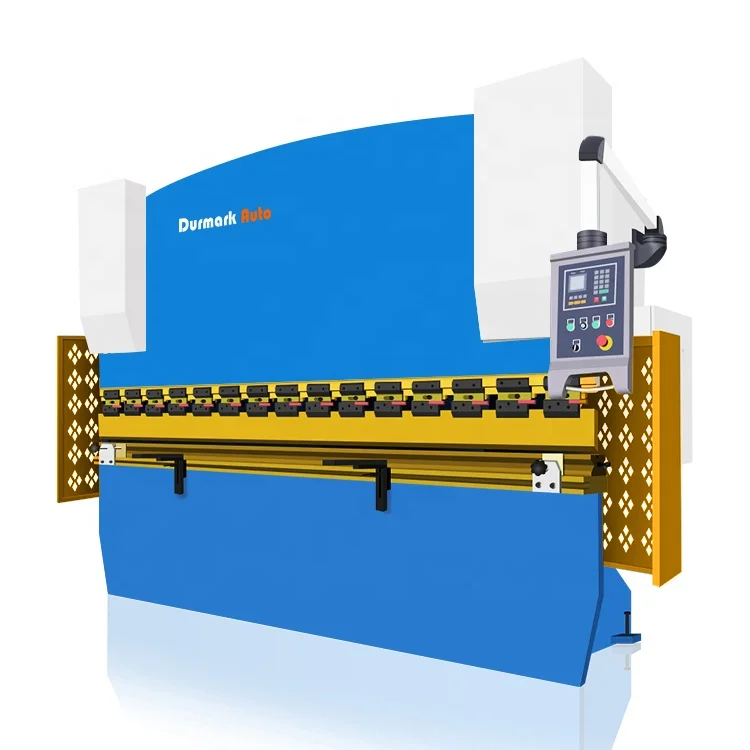

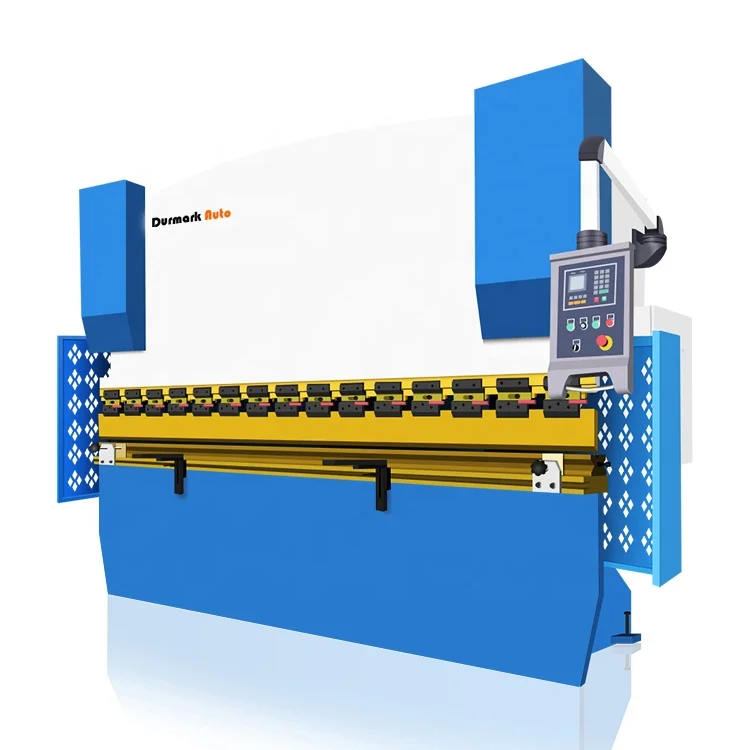

Durmark brand hydraulic 5.5w power press brake with E30 system cnc bending machine

- Category: >>>

- Supplier: Anhui Lifu Machinery Technology Co. Ltd.

Share on (1600617006050):

Product Overview

Description

Durmark brand hydraulic 5.5w power press brake with E30 system cnc bending machine

This WC67K-125T3200press brake uses the self-developed E30 control system with Angle compensation functionAnhui Lifu Machinery Technology Co.,Ltd.is a leading Chinese sheet metal processing machinery and construction machinery exporter and importer,Located in Bowang, Ma'anshan.

E30 SYSTEM

Come from Durmark China

E21 SYSTEM

Come from Estun China

Anhui LIFU Machinery Technology Co., Ltd. is a design, development, production and sales of an integrated company. Our main development direction is producing different CNC machineries to realize of mechanical automation. Focus on R&D in technology, and have a complete R & D team, a total of 16 senior engineers for design, drawing, optimization, etc.

In addition, we have long-term close cooperation with domestic well-known Metal forming Machinery Research Institute, cutting off stamping machinery surrounding automation equipment manufacturers, and CNC automation control system manufacturers.

The company occupies an area of about 100,000 square meters, of which about office space 2,000 square meters , a semi-finished workshop about 6,000 square meters, finishing department about 8,000 square meters, welding workshop about 4,000 square meters, Grinding processing workshops about 2,000 square meters, a variety of spare parts warehouse of about 2,000 square meters. With improved processing power, equipped with large CNC pentahedrons processing center, two sets large boring and milling machine, four sets large gantry milling machine, two sets vertical boring machine, one set large horizontal lathe with max 600mm process diameter,

In addition, we have long-term close cooperation with domestic well-known Metal forming Machinery Research Institute, cutting off stamping machinery surrounding automation equipment manufacturers, and CNC automation control system manufacturers.

The company occupies an area of about 100,000 square meters, of which about office space 2,000 square meters , a semi-finished workshop about 6,000 square meters, finishing department about 8,000 square meters, welding workshop about 4,000 square meters, Grinding processing workshops about 2,000 square meters, a variety of spare parts warehouse of about 2,000 square meters. With improved processing power, equipped with large CNC pentahedrons processing center, two sets large boring and milling machine, four sets large gantry milling machine, two sets vertical boring machine, one set large horizontal lathe with max 600mm process diameter,

Web://www.durmark-machinery.com

Product Description

CNC press brake

*The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

*The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

*1. High bending precision,fast working speed, and efficient,operational safety,performance stably.

*2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

*3. Using international brand parts and cnc. cnc hydraulic press brake | cnc hydraulic press brake | cnc press brake

*4. Visual operating system,easy operation,convenient,multi-functions and practical.

*5. All parts are produced by cnc produce center,according to standard drawing.

*6. High executive force,high standard and high professional machine assembled team.

*7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

*8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

*9. Providing comprehensive bending program for all press brake,shearing machine user.

*10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

*11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

*12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

*13.The similarity of images and shipping machine can reach 99.5%.

*14.In time fast delivery.

*2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

*3. Using international brand parts and cnc. cnc hydraulic press brake | cnc hydraulic press brake | cnc press brake

*4. Visual operating system,easy operation,convenient,multi-functions and practical.

*5. All parts are produced by cnc produce center,according to standard drawing.

*6. High executive force,high standard and high professional machine assembled team.

*7. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

*8. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation.

*9. Providing comprehensive bending program for all press brake,shearing machine user.

*10.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

*11.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.

*12.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

*13.The similarity of images and shipping machine can reach 99.5%.

*14.In time fast delivery.

Machine frame processing:

A large floor boring and milling machine is used for overall processing of the bending machine frame.

Forced synchronization of mechanical torsion shaft:

Forged material shaft body, with high rigidity and good elasticity, with fine adjustment device, weak anti-eccentric load.

Type | WC67K-63T2500 |

Nominal pressure(KN) | 630 |

Length of table(mm) | 2500 |

Throat depth(mm) | 230 |

Ram stroke(mm) | 80 |

Main motor(kw) | 5.5 |

Weight(kg) | 4000 |

Overall dimensions L*W*H(mm) | 2800*1600*2100 |

Detailed Images

1.Moter

Use international famous brand motor

Use SUNNY and FIRST oil pump

Well-known hydraulic system, high stability

2.Bracket and mould

The 45# forging material is used for the mold. High temperature heat treatment after processing

Adopt convenient and fast hauling arm, can adjust up and down

Standard mold specification: 150*26mm

Adopt convenient and fast hauling arm, can adjust up and down

Standard mold specification: 150*26mm

3.Back gauge

Double linear guide rail, high precision, ensure straightness

X-axis CNC rear gear, can be manually moved around, fine adjustment, high precision, up to ±0.02 mm.

X-axis CNC rear gear, can be manually moved around, fine adjustment, high precision, up to ±0.02 mm.

4.Electrical Box

Using Schneider ,ensure the safe and stable operation of machine tools.

Schneider is used to ensure the safe and stable operation of the machine.

Adopt frequency conversion technology

Relay: Schneider

Voltage regulator: Schneider

Air switch: Schneider

Electrical cabinet with open door power off function

Adopt frequency conversion technology

Relay: Schneider

Voltage regulator: Schneider

Air switch: Schneider

Electrical cabinet with open door power off function

5.Foot Switch

Certification: CE

Ambient temperature: -25 degrees +70 degrees

Ambient humidity: 45%-85%RH

Protection level: IP65

Aluminium alloy casting molding

Baked plastic treatment, abrasion and impact resistance

Three sides protection

With emergency stop button

Comes with spring cable lock

Ambient temperature: -25 degrees +70 degrees

Ambient humidity: 45%-85%RH

Protection level: IP65

Aluminium alloy casting molding

Baked plastic treatment, abrasion and impact resistance

Three sides protection

With emergency stop button

Comes with spring cable lock

6.E30 control system

Hd liquid crystal display, English and Chinese language

One page display programming,

Intelligent positioning of X and Y axes

Built-in pressure holding time, unloading delay setting function

Parameter One-click backup and reply function

Multi - step programming, complex workpiece processing completed at one time

Touch screen

Built-in Angle compensation function

One page display programming,

Intelligent positioning of X and Y axes

Built-in pressure holding time, unloading delay setting function

Parameter One-click backup and reply function

Multi - step programming, complex workpiece processing completed at one time

Touch screen

Built-in Angle compensation function

7.Stroke control

Stroke control: Adopt high precision displacement sensor

Using magnetostrictive principle, the intersection of two different magnetic fields generates a strain pulse signal to accurately measure the position. The measuring element is a waveguide, and the sensitive element in the waveguide tube is made of special magnetostrictive material. The measurement process is generated by current pulses in the sensor's electronics chamber.

Our service&Workshop

You can contact me at anytime,we will provide you fast and professional service.

Advantage

1. Competitive price: It is can meet your budget and best-selling business very well.

2. OEM Accepted: We can produce any your request design.

3. Good Service: We treat clients as friends.

4. Good Quality: We have strict quality control system. Good reputation in the market.

5. Fast & Delivery: We have big discount from forwarder (Long Contract).

Our Innovation

Quality & Service: At durmark auto, our priority has always been providing our clients with great quality products and superior customerservice.

Quick lead Time: We are dedicated to providing the quickest turn-around times and work very hard to ensure that all of your deadlines are met.

Unbeatable Prices: We continuously strive to find ways of reducing our production costs, and passing the saving over to you!

Brand Awareness: The goal of any strong brand is achieve a level of awareness that instills the idea of quality and value into al lof your potential customers.

Special Offers: In order to maintain our competitive edge, we are constantly running special offers on our Best –selling

pressbrake, forging equipment goods and design services. Contact our sales term to see how we can help you save a lot of money.

General Order Information

We take great pride in our work and in the wide variety of products that we offer. We are experienced in servicing the Southeast Asia market, South America, European market and Africa market. Please be aware that our production lead times depend on specific items and item quantities.

Advantage

1. Competitive price: It is can meet your budget and best-selling business very well.

2. OEM Accepted: We can produce any your request design.

3. Good Service: We treat clients as friends.

4. Good Quality: We have strict quality control system. Good reputation in the market.

5. Fast & Delivery: We have big discount from forwarder (Long Contract).

Our Innovation

Quality & Service: At durmark auto, our priority has always been providing our clients with great quality products and superior customerservice.

Quick lead Time: We are dedicated to providing the quickest turn-around times and work very hard to ensure that all of your deadlines are met.

Unbeatable Prices: We continuously strive to find ways of reducing our production costs, and passing the saving over to you!

Brand Awareness: The goal of any strong brand is achieve a level of awareness that instills the idea of quality and value into al lof your potential customers.

Special Offers: In order to maintain our competitive edge, we are constantly running special offers on our Best –selling

pressbrake, forging equipment goods and design services. Contact our sales term to see how we can help you save a lot of money.

General Order Information

We take great pride in our work and in the wide variety of products that we offer. We are experienced in servicing the Southeast Asia market, South America, European market and Africa market. Please be aware that our production lead times depend on specific items and item quantities.

Customer Photos

Exhibition

Packing and Shipping

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Ma’anshan City ,Anhui Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Ma’anshan City ,Anhui Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .

6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

A: 1 set .(Only some low cost machines will be more than 1 set )

We Recommend

New Arrivals

New products from manufacturers at wholesale prices