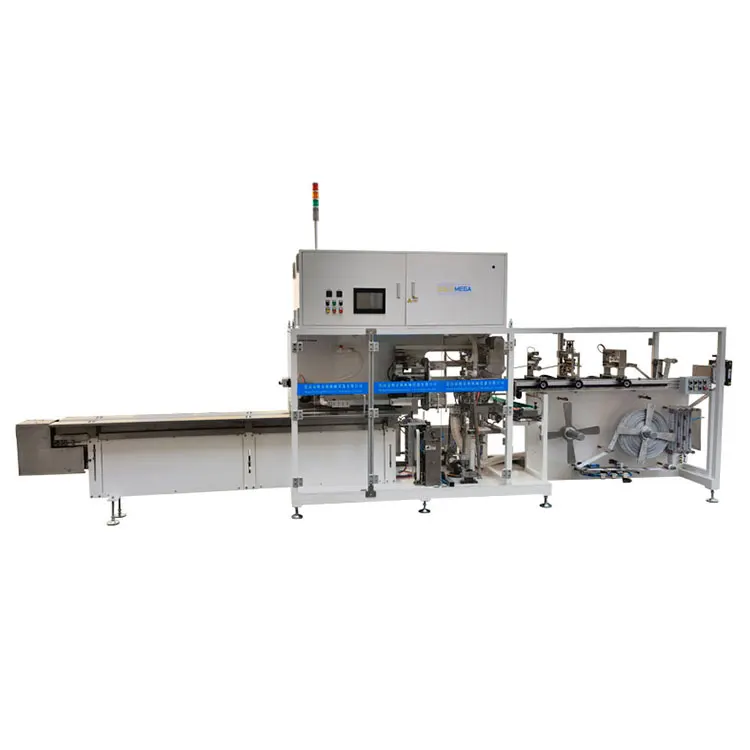

Gold mega Sanitary Pad Packaging Machine roll film premade bag sanitary pad napkin packing machine

- Category: >>>

- Supplier: Kunshan Mega-Packing Machinery Equipment Co. Ltd.

Share on (1600621607488):

Product Overview

Description

Product Overview

Feature

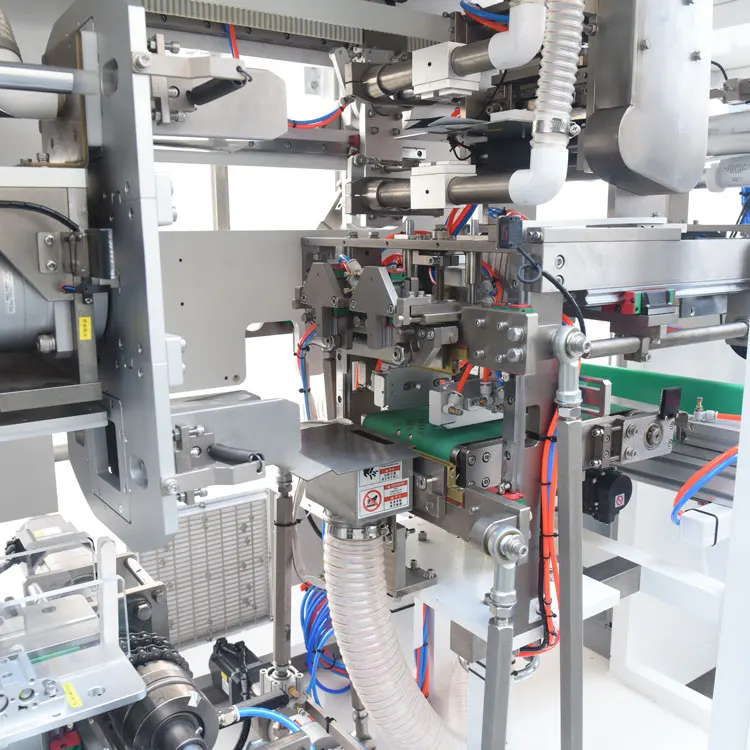

1.Full servo drive:

The whole machine adopts Japanese Mitsubishi motion controller and PLC double CPU bus servo drive system,

The whole machine adopts Japanese Mitsubishi motion controller and PLC double CPU bus servo drive system,

each servo motor transmission adopts synchronous virtual mode control, with extremely high packaging precision

and excellent stability.

2.Molding Mechanism:

Inserting Angle dislocation small, stable Angle, straight line;

3.Bag opening mechanism: The bag-opening mechanism adopts servo control, which can adapt to different packing specifications and adjust the parameters conveniently and quickly.

4. Very short trimming material:

Under the condition of ensuring forming stability, it can control the shortest length of the edge material, that is

the width of the sealing tail is less than or equal to 10mm

5.Product Packaging Specifications

It is suitable for horizontal or vertical packing, compatible with wafer sanitary pad packing, single or multi-row packing;

6.Woking efficiency.

Open probability ≥85%, unwinding device, one roll for use, one roll for standby to meet the production needs,

can achieve non-stop feeding, save film changing time, improve work efficiency.

7.Humanized man-machine interface:

Save up to 20 kinds of product parameters, change varieties only need to call formula parameters, convenient and quick

8. Fault Diagnosis:

The touch screen has the function of abnormal alarm display. When the equipment itself fails or is abnormal, the equipment will send out the corresponding alarm prompt to facilitate maintenance and troubleshooting

9. On-line mode:

It can operate independently and put materials manually,and also can be connected to the stacker, automatic connection, automatic counting, automatic feeding and automatic packaging, with high degree of automation

and excellent stability.

2.Molding Mechanism:

Inserting Angle dislocation small, stable Angle, straight line;

3.Bag opening mechanism: The bag-opening mechanism adopts servo control, which can adapt to different packing specifications and adjust the parameters conveniently and quickly.

4. Very short trimming material:

Under the condition of ensuring forming stability, it can control the shortest length of the edge material, that is

the width of the sealing tail is less than or equal to 10mm

5.Product Packaging Specifications

It is suitable for horizontal or vertical packing, compatible with wafer sanitary pad packing, single or multi-row packing;

6.Woking efficiency.

Open probability ≥85%, unwinding device, one roll for use, one roll for standby to meet the production needs,

can achieve non-stop feeding, save film changing time, improve work efficiency.

7.Humanized man-machine interface:

Save up to 20 kinds of product parameters, change varieties only need to call formula parameters, convenient and quick

8. Fault Diagnosis:

The touch screen has the function of abnormal alarm display. When the equipment itself fails or is abnormal, the equipment will send out the corresponding alarm prompt to facilitate maintenance and troubleshooting

9. On-line mode:

It can operate independently and put materials manually,and also can be connected to the stacker, automatic connection, automatic counting, automatic feeding and automatic packaging, with high degree of automation

Product Model | MG-SP100A |

Packing Speed | Design 75 bags/min, actual running speed of 50-60 bags/min |

Qualification Rate | ≥98% |

Packing Mode | Horizontal or vertical, using tube film,on-line bag making |

Tube Film Material | PE film, composite film, aluminized film, single layer thickness of film ≤70um |

Packing Bag Dimension | L(75-200)*W(60-120)*H(30-110)mm,customized |

Machine Size | L6500mm x W1200mm x H2200mm |

Machine Weight | Above 2500KG |

Power | Above 15KW |

Power Requirements | (R、S、T、N、PE),AC380V,50/60HZ Three-phase five-wire system (R, S, T, N, PE) |

Air Source Requirement | Air pressure 0.5-0.8Mpa,Air consumption Max.300LPM |

Main Pneumatic&Electrical List

Packing & Delivery

Certificate

Company Workshop

FAQ

1.Q: How to find a Packing machine suitable for my product?

A:Tell me about your product details. 1. What kind of product you have. 2. The size of your product( the length, width, and height).

2.Q: Is an engineer available to serve oversea?

A:Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

3.Q: Are you a factory or trading company?

A:We are the factory, and especially R&D, manufacture and sell various packing equipment. We have engaged in the packing R&D and production for over 10 years.

4.Q: What's your payment way?

A:T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, L/C, or in cash.

5.Q: How can we make sure about the machine quality after we put the order?

A:Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

6.Q:We are afraid you won't send us the machine after we send you the money?

A:Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

7.Q: Why we should choose your company?

A:We are professional in packing machines for almost 20 years, and we provide better after-sales service. You guarantee no risk for our deal.

Contact Us

Kunshan Mega-Packing Machinery Equipment Co.,Ltd

Sales Manager: Tina

PH:+86 512 57290650

TEL&WhatsAPP: +86 183 6198 1795

Email:sales001@mega-packing.com

Foreign Trade Specialist: Sophia

TEL&WhatsAPP: +86 133 9087 6758

Email:sales29@mega-packing.com

Add: No.2 workshop,No.625,Jingtang South Road,Qiandeng

Town,Kunshan city,Jiangsu.China(215341)

Sales Manager: Tina

PH:+86 512 57290650

TEL&WhatsAPP: +86 183 6198 1795

Email:sales001@mega-packing.com

Foreign Trade Specialist: Sophia

TEL&WhatsAPP: +86 133 9087 6758

Email:sales29@mega-packing.com

Add: No.2 workshop,No.625,Jingtang South Road,Qiandeng

Town,Kunshan city,Jiangsu.China(215341)

We Recommend

New Arrivals

New products from manufacturers at wholesale prices