Hydraulic cnc bending machine With Promotional Price guillotine shear blade

- Category: >>>

- Supplier: Nantong Pacific CNC Machine Tool Co. Ltd.

Share on (1600624309164):

Product Overview

Description

GUILLOTINE SHEARING MACHINE

Cutting steel plate materials of various thicknesses.

High accuracy, high efficiency simple

Convenient operation good performance.

High accuracy, high efficiency simple

Convenient operation good performance.

Standard Accessories

1. E21S-Estun: digital monitor to display the position of the back gauge

2. Germany hydraulic system

3. SUNNY, USA oil pump with slide-in pipes joints

4. Back gauge is moved with T-screw shaft, guided by rod-shaft and driven by AC motor

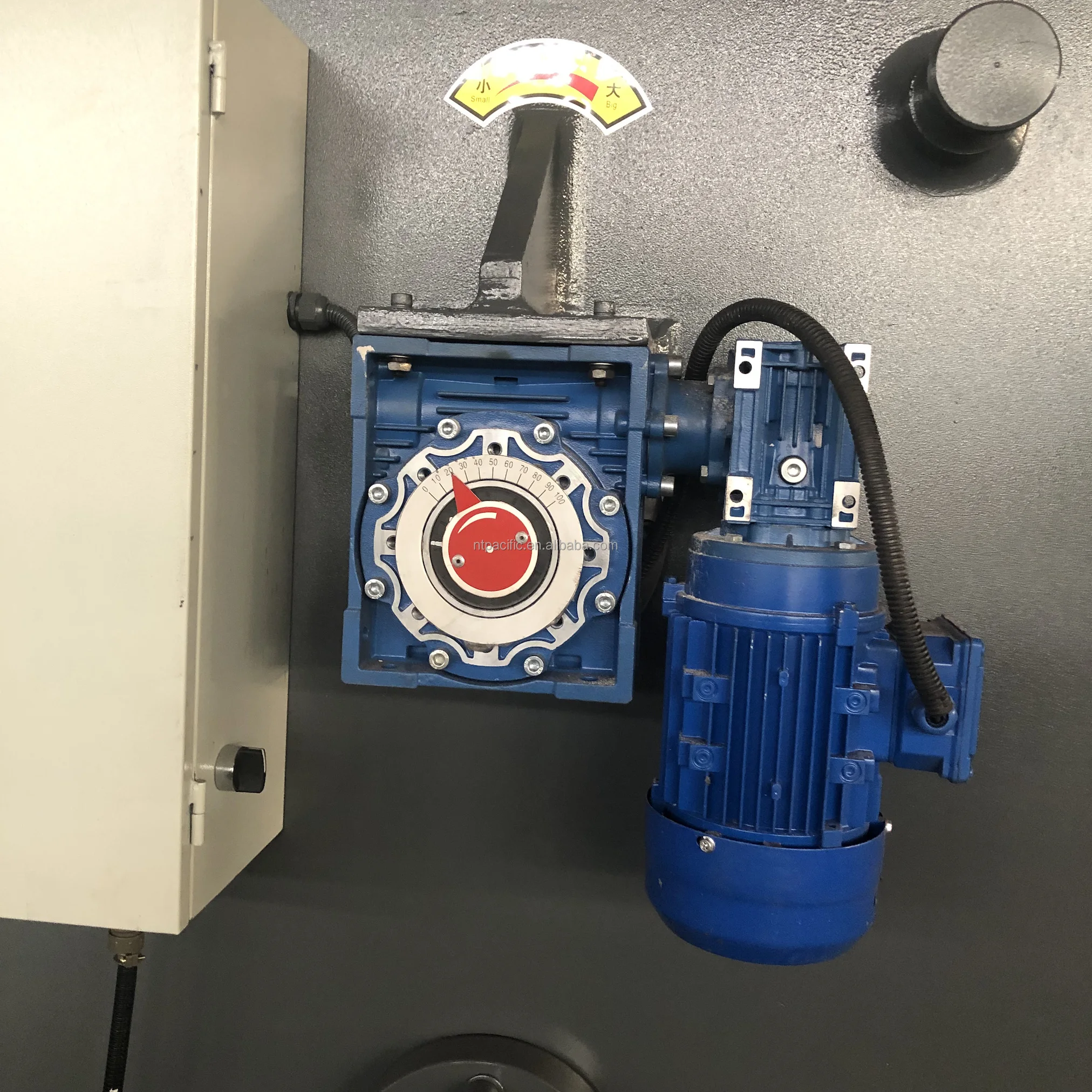

5. Motorized adjustment of blade gap and shearing angle

6. Hydraulic hold downs with sequential operation

7. Moveable foot switch

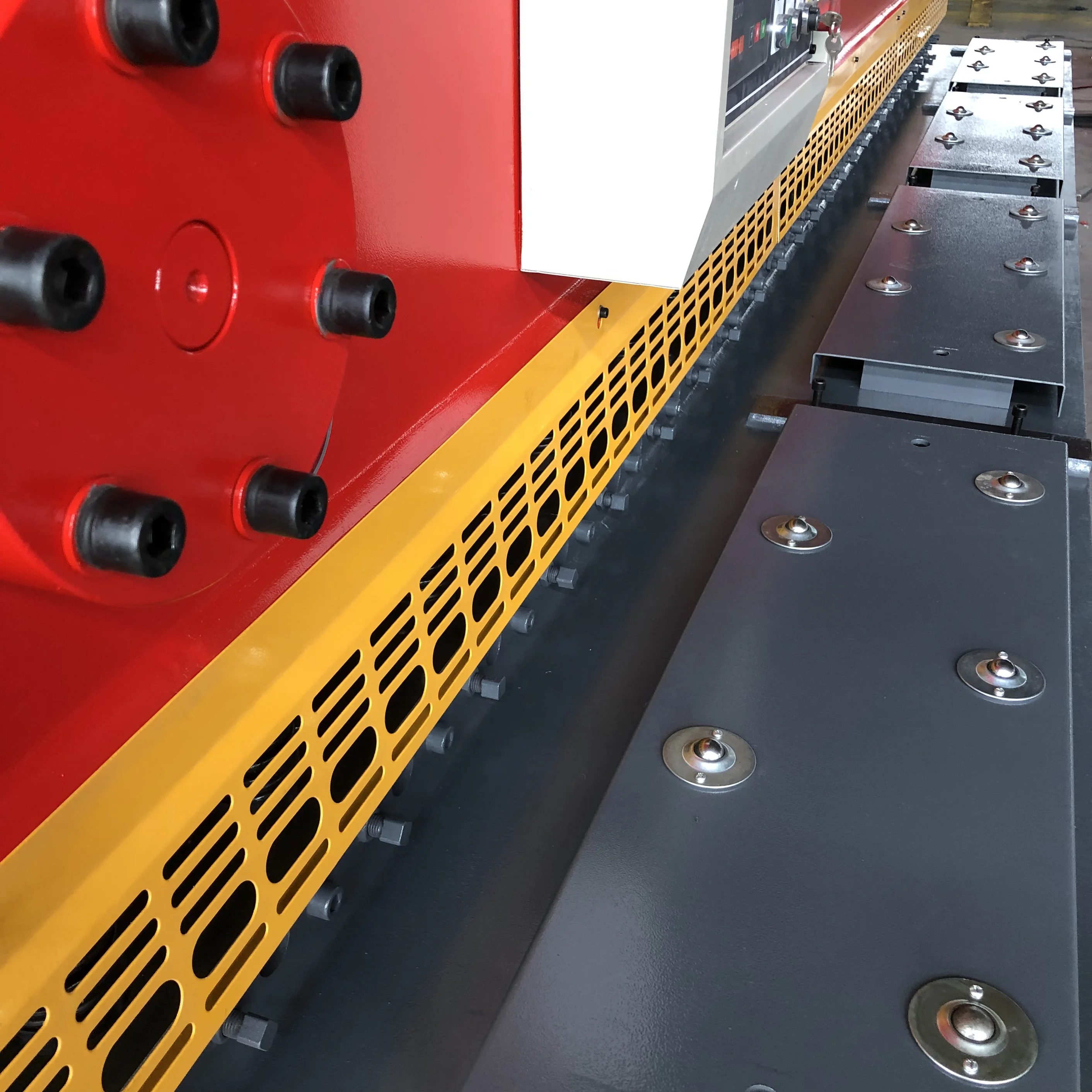

8. Finger guard

9. One set of standard blade (upper and lower) materials is 6CrW2Si

10. Front support arms with length 1000mm

11. Ball worktable ,reduce the contact between sheet plate and machine work table

12. Often-used internal hexagonal key spanner for adjusting blades

13. Comprehensive instruction & maintenance manual

2. Germany hydraulic system

3. SUNNY, USA oil pump with slide-in pipes joints

4. Back gauge is moved with T-screw shaft, guided by rod-shaft and driven by AC motor

5. Motorized adjustment of blade gap and shearing angle

6. Hydraulic hold downs with sequential operation

7. Moveable foot switch

8. Finger guard

9. One set of standard blade (upper and lower) materials is 6CrW2Si

10. Front support arms with length 1000mm

11. Ball worktable ,reduce the contact between sheet plate and machine work table

12. Often-used internal hexagonal key spanner for adjusting blades

13. Comprehensive instruction & maintenance manual

Optional Accessories

1. DAC360 , Netherlands CNC controller

2. Backgauge with ball screw and linear guideway ,drive by AC Servo motor

3. Automatic cutting angle and blade gap

4. 6CrW2Si blade changed to Cr12MoV blade (for cutting stainless steel)

5. Pneumatic out table device for cutting piece falling smooth.

2. Backgauge with ball screw and linear guideway ,drive by AC Servo motor

3. Automatic cutting angle and blade gap

4. 6CrW2Si blade changed to Cr12MoV blade (for cutting stainless steel)

5. Pneumatic out table device for cutting piece falling smooth.

Built-in Spring Pressure Cylinder

Built-in spring pressure cylinder,its lower end equipped with special material gasket,separately control the pressure,avoiding

aluminium alloy or other softor materials being imprinted

aluminium alloy or other softor materials being imprinted

Workbench

Delicate desingn is convenienfor cutting petty materials by hand.

Hydraulic Valve

Hydraulic transmission with high reliability,integrated dydraulic system can effectivelyalleviate problems caused by leakage of hydraulic fluid,

Motor

Using Siemens moter guarantees the machine service life,

and reduce the noise when working.

and reduce the noise when working.

Controller

E21S controller cantilever device,referrinigto man-machine engineering deign principle,easy CNC system operation

surface,significantly improving the operation precision and comfortability

surface,significantly improving the operation precision and comfortability

Optional Configuration

Pneumatic Back Supporter

Pneumatic back supporting device keeps thin sheet,cutting workbench and back stopper parallelto ensure accurate cutting sixe,avoid the sheet deviating designed position and extended parts saging.

Model (QC11K Series) | Mild Steel (450Mpa) | Cutting Length(mm) | Depth of Throat (mm) | Back Gauge Range(mm) | Rake Angle Adjustment | Strokes Per Minute | Main Motor (kw) | LxWxH(mm) |

4x2000 | 4 | 2000 | 80 | 600 | 0.5°~2° | 14 | 5.5 | 2600*1680*1750 |

4x2500 | 4 | 2500 | 80 | 600 | 0.5°~2° | 14 | 5.5 | 3100*1750*1765 |

6x2500 | 6 | 2500 | 80 | 750 | 0.5°~1°30′ | 14 | 7.5 | 3100*1725*1900 |

6x3200 | 6 | 3200 | 80 | 750 | 0.5°~1°30′ | 12 | 7.5 | 3935*1840*1995 |

6x4000 | 6 | 4000 | 80 | 750 | 0.5°~1°30′ | 10 | 7.5 | 4650*1840*2100 |

6x5000 | 6 | 5000 | 80 | 750 | 0.5°~1°30′ | 8 | 11 | 5650*2185*2380 |

6x6000 | 6 | 6000 | 80 | 750 | 0.5°~1°30′ | 8 | 11 | 6650*2260*2380 |

8x2500 | 8 | 2500 | 80 | 750 | 0.5°~1°30′ | 14 | 11 | 3135*1840*2075 |

8x3200 | 8 | 3200 | 80 | 750 | 0.5°~1°30′ | 12 | 11 | 3850*1990*2050 |

8x4000 | 8 | 4000 | 80 | 750 | 0.5°~1°30′ | 10 | 11 | 4650*2030*2075 |

8x5000 | 8 | 5000 | 80 | 750 | 0.5°~2° | 7 | 15 | 5650*2050*2400 |

8x6000 | 8 | 6000 | 100 | 750 | 0.5°~2° | 7 | 15 | 6805*2115*2715 |

10x2500 | 10 | 2500 | 100 | 750 | 0.5°~2°30′ | 10 | 15 | 3195*1915*2205 |

10x3200 | 10 | 3200 | 100 | 750 | 0.5°~2°30′ | 8 | 15 | 3895*1900*2235 |

10x4000 | 10 | 4000 | 100 | 750 | 0.5°~2°30′ | 6 | 15 | 4695*1970*2270 |

10x5000 | 10 | 5000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 5700*2115*2715 |

10x6000 | 10 | 6000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 6905*2115*2800 |

12x2500 | 12 | 2500 | 100 | 750 | 0.5°~2°30′ | 10 | 15 | 3195*2000*2210 |

12x3200 | 12 | 3200 | 100 | 750 | 0.5°~2°30′ | 8 | 15 | 3895*2050*2240 |

12x4000 | 12 | 4000 | 100 | 750 | 0.5°~2°30′ | 5 | 15 | 4710*2110*2450 |

12x5000 | 12 | 5000 | 100 | 750 | 0.5°~2°30′ | 5 | 18.5 | 5750*2115*2800 |

12x6000 | 12 | 6000 | 100 | 750 | 0.5°~2°30′ | 5 | 30 | 7150*2300*3100 |

16x2500 | 16 | 2500 | 100 | 750 | 0.5°~2°30′ | 8 | 18.5 | 3215*1970*2340 |

16x3200 | 16 | 3200 | 100 | 750 | 0.5°~2°30′ | 7 | 22 | 3915*1970*2455 |

16x4000 | 16 | 4000 | 100 | 750 | 0.5°~2°30′ | 6 | 22 | 4715*2010*2590 |

16x5000 | 16 | 5000 | 100 | 750 | 0.5°~3° | 5 | 30 | 6000*2300*3000 |

16x6000 | 16 | 6000 | 80 | 750 | 0.5°~3° | 5 | 37 | 7250*2400*3100 |

20x2500 | 20 | 2500 | 100 | 750 | 0.5°~3° | 6 | 22 | 3235*2020*2465 |

20x3200 | 20 | 3200 | 120 | 750 | 0.5°~3° | 5 | 30 | 4150*2065*2755 |

20x4000 | 20 | 4000 | 120 | 750 | 0.5°~3° | 4 | 30 | 4955*2125*2885 |

20x5000 | 20 | 5000 | 120 | 750 | 0.5°~3° | 4 | 37 | 6000*2300*3050 |

25x2500 | 25 | 2500 | 120 | 750 | 0.5°~3.5° | 5 | 37 | 3465*2130*2710 |

25x3200 | 25 | 3200 | 120 | 750 | 0.5°~3.5° | 5 | 37 | 4120*2200*3000 |

25x4000 | 25 | 4000 | 120 | 750 | 0.5°~3.5° | 4 | 37 | 4950*2200*3150 |

30x2500 | 30 | 2500 | 120 | 750 | 0.5°~3.5° | 4 | 37 | 3405*2170*2770 |

30x3200 | 30 | 3200 | 120 | 750 | 1°~3.5° | 3 | 45 | 4200*2300*3200 |

40x2500 | 40 | 2500 | 180 | 750 | 1°~4° | 4 | 45 | 3770*2550*3400 |

40x3200 | 40 | 3200 | 180 | 750 | 1°~4° | 4 | 55 | 3770*2550*3400 |

Q1. How about the quality of your machines?

Our company is the key backbone enterprise of the national machinery industry, with a group of experienced professional engineering and technical personnel, production and testing equipment, with 20 years of product manufacturing experience.We are committed to customer satisfaction is our pursuit, quality must make customers satisfied.

Q2. Can you give me a better price for the machine?

1.The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

2.We will definitely provide quality = price, price = quality, and the matching price is acceptable to the customer.We welcome you to negotiate with us and obtain good satisfaction.

3.As a factory, we have an advantage in price.

Q3. How can we provide you efficient services (metal processing solution)?

There are Three Steps as following:

Our company is the key backbone enterprise of the national machinery industry, with a group of experienced professional engineering and technical personnel, production and testing equipment, with 20 years of product manufacturing experience.We are committed to customer satisfaction is our pursuit, quality must make customers satisfied.

Q2. Can you give me a better price for the machine?

1.The quality of the company's products is always good, and we know that the overseas market is more important and difficult than the domestic market.Due to the time cost of after-sales communication, our machines are always of higher quality to ensure that they can work beyond the true warranty period.

2.We will definitely provide quality = price, price = quality, and the matching price is acceptable to the customer.We welcome you to negotiate with us and obtain good satisfaction.

3.As a factory, we have an advantage in price.

Q3. How can we provide you efficient services (metal processing solution)?

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional

recommendations ;reg. non-standard products, we can offer professional designing.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional

recommendations ;reg. non-standard products, we can offer professional designing.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices