50 To 350mm PCB DIP Production Line Solder Machine Automatic Dual Mini Wave Soldering Machine

- Category: >>>

- Supplier: Chipbest Technology (Dongguan) Co. Ltd.

Share on (1600629174771):

Product Overview

Description

50 To 350mm PCB DIP Production Line Solder Machine Automatic Dual Mini Wave Soldering Machine

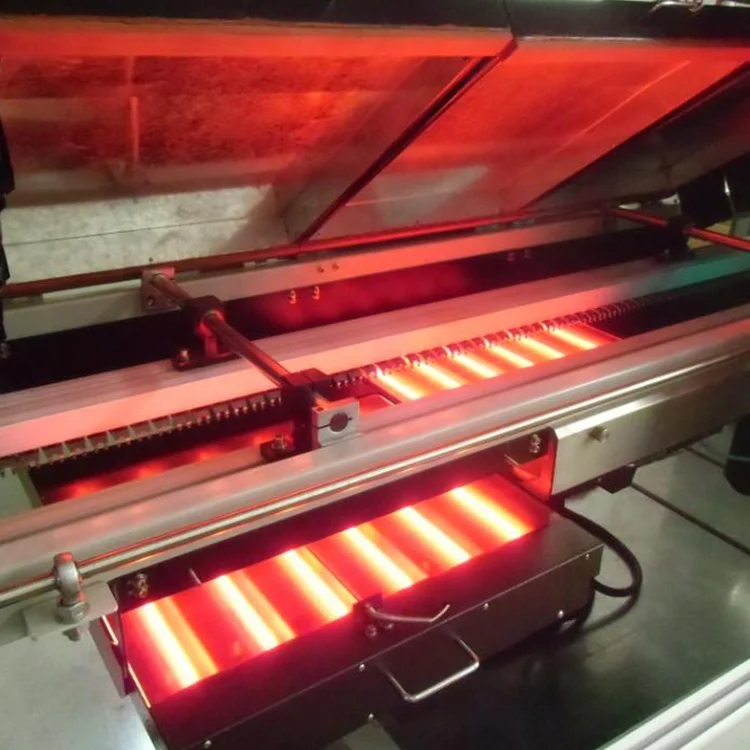

Machine Introduction:This is a lead-free wave soldering machine, its unparalleled heating performance and temperature control system meet the requirements of various welding processes, especially energy saving design has been a leading-edge product advantage, maximum reducing the using cost for customers.

Technical parameters:

| Model Name | JS-FMW-350C China Factories SMT Reflow Oven And Wave Soldering Machine PCB Wave Solder Machine For Assembly Line |

| PCB Width | 50~350mm(W)*120mm(H) |

| PCB entrance height | 750±20mm |

| Transmission speed | 500~1800mm/Min |

| Conveyor Angle | 4~7° |

| Conveying Direction | From L to R |

| Flux Capacity | 18 Lit |

| Spray fan | Approx.30m3/min |

| Compressed air | 4~6Bar. 100L/min |

| Pre-heater temp | Max.200ºC |

| Solder pot temp | Max.300ºC |

| Solder Capacity | Approx.500Kg |

| Wave height | Approx.12mm |

| Machine size | 3600(L)*1420(W)*1750(H)mm |

| Machine weight | Approx.1250Kg |

| Power supply | Three-phase 380V AC 50Hz |

| Running power | Approx.8KW |

Machine Features:

1. Nozzle: Japan Kuroda Seiko nozzles, adjustable atomizing area, ensuring the long time spray uniformity and reliability.

2. Spray control: computer control or manually adjust switch, precise control the spray time, spray speed, economy and environmental protection, digital FLUX flow, spray flow, angle, density, width and other parameters can be recorded.

3. Cleaning device: automatic cleaning, modular design, easy maintenance.

4. Temperature Protection: third-party over-temperature protection, multiple protection layers to ensure safe operation.

5. Products comply with CE, CCC, UL and other standards and specifications.

6. User-friendly design: fault detection (such as heaters abnormal alarm, etc.), regular maintenance reminders,economy functions, emergency manual transmission function and tool-free maintenance, reduce equipment failure rates.

7. Heating module: horizontal reflow design makes each heating zones not influenced by adjacent zones to ensure accurate temperature curve, while ensuring high production capacity and heat exchange capacity, and achieve high adaptive capacity (to meet the soldering of automotive electronics, communications, electronics, computers and mobile phones, and other consumer electronics.

2. Spray control: computer control or manually adjust switch, precise control the spray time, spray speed, economy and environmental protection, digital FLUX flow, spray flow, angle, density, width and other parameters can be recorded.

3. Cleaning device: automatic cleaning, modular design, easy maintenance.

4. Temperature Protection: third-party over-temperature protection, multiple protection layers to ensure safe operation.

5. Products comply with CE, CCC, UL and other standards and specifications.

6. User-friendly design: fault detection (such as heaters abnormal alarm, etc.), regular maintenance reminders,economy functions, emergency manual transmission function and tool-free maintenance, reduce equipment failure rates.

7. Heating module: horizontal reflow design makes each heating zones not influenced by adjacent zones to ensure accurate temperature curve, while ensuring high production capacity and heat exchange capacity, and achieve high adaptive capacity (to meet the soldering of automotive electronics, communications, electronics, computers and mobile phones, and other consumer electronics.

Machine Advantages:

1.Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn, easy to maintain.

2. Expertise: learn imported reflow oven's advanced design concepts, and the components are using imported top brands.

3. Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

4. Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

5. Stable: mature software, hardware and top production processes ensures stability of each equipment.

2. Expertise: learn imported reflow oven's advanced design concepts, and the components are using imported top brands.

3. Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

4. Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

5. Stable: mature software, hardware and top production processes ensures stability of each equipment.

Packaging :

We Recommend

New Arrivals

New products from manufacturers at wholesale prices