Home Mini 1KW 2KW 5KW 10KW Small Generators Price Pole Vertical Axis Blades Axial Flux Controller Wind Turbines

- Category: >>>

- Supplier: Guangzhou Engineering Plastics Industries (group) Co. Ltd.

Share on (1600658156557):

Product Overview

Description

Product Display

Horizontal Wind Turbine ODM/OEM Service

We have a professional engineer team to design custom parts for your needs , we also have ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

If you have any problems or want to get the quoted price of any plastics ormachined components, please feel free to contact us. Our engineers will reply to you as soon as possible.

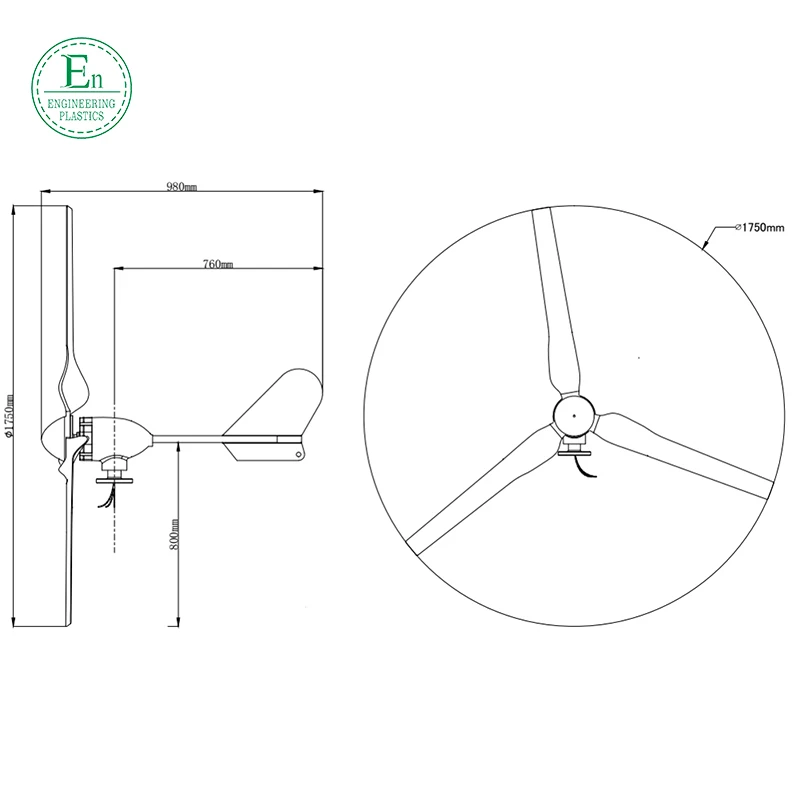

Prouduct Parameters

Model | EQ-600M1 | ||||||

Rated power | 600W | ||||||

Maximum power | 680W | ||||||

Rated voltage | 12/24V | ||||||

Start-up wind speed | 2.5m/s | ||||||

Rated wind speed | 10m/s | ||||||

Survival wind speed | 55m/s | ||||||

Top net weight | 15kg | ||||||

Wheel diameter | 1.75m | ||||||

Number of blades | 3 | ||||||

Blades material | Nylon fiber | ||||||

Generator type | Three phase permanent magnet AC synchronous generator | ||||||

Magnet material | NdFeB | ||||||

Generator case | Casting aluminum alloy | ||||||

Control system | Electromagnet/wind wheel yaw | ||||||

Speed regulation | Automatically adjust windward direction | ||||||

Working temperature | -40°C - 80°C | ||||||

Design life | 20 y | ||||||

Certificates | CE, ISO14001,ISO 9001, TUV | ||||||

wind generator system

System Drawing of Wind/ Solar Hybrid With Diesel System

In the days without wind and solar, the electric energy output from wind generator and solar panel is insufficient for the battery charging, then the battery banks shall be under voltage,

our controller will automatically switch to diesel generator to supply power for the AC load.

Guangdong Engineering Plastics Industries (Group) Co. Ltd.

We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for more than 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design, research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines,such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

We have the professional engineer teams and sales teams, and we have technology and experiences in engineering plastic industry for more than 15 years! Our company is located in Huangpu District, Guangzhou City, China, where the logistics is developed! With the rich experiences and technology for manufacture, design, research and development ability, support personalized customization. We have full set of high efficiency producing equipment and advanced numerical control machines,such as: molding injection machines, CNC molding manufacture machines, fine carving machines, Horizontal lathes, milling machines. We can customize all kinds of Engineering plastics products according to our customers’drawings or samples.

name | Professional high-precision molds and injection molded parts10 | ||||||

color | white,black,green,nature,blue,yellow,etc | ||||||

material | ABS,PMMA,PC,PP,PEEK,PU,PA,PA+GF,POM,PE,UPE,PTFE,etc | ||||||

mould cavity | single cavity & multi cavity | ||||||

runner system | hot runner and cold runner | ||||||

equipment | CNC, EDM, cutting off machine,plastic machinery etc | ||||||

mould material | P20/ 718H/ S136H/ S136 hardened/ NAK80 | ||||||

injection machine | 7sets,88T, 90T, 120T, 168T, 200T, 380T,420T,1200T | ||||||

mould life | 300000-500000 shots as per customers' requirement | ||||||

size | 5-1000mm,or customized | ||||||

tolerance | ± 0.05mm | ||||||

shape | as per your drawing or the sample | ||||||

certification | ISO9001 and relate whole set professional test report | ||||||

free sample | available | ||||||

advantage | one stop procurement | ||||||

Application field | Various plastic injection molded parts for various industrial and automotive applications | ||||||

lead time | 25-35 days for mould,plastic products according to quantity | ||||||

other | 1.24 hours instant and comfortable customer service 2.shipping status notification during delivery 3.regular notification of new styles & hot selling styles | ||||||

The factory covers an area of 10,000 square meters Production equipment has the original American imported Haas CNC machining center, wire-electrode cutting, electrical discharge machine,Perforating machine, injection molding machine, CNC milling machine ,CNC hobbing machine, CNC lathe, CNC milling machine, CNC lathe, CNC milling machine, grinding machine and other machinery and equipment.

Our company is developing in the mode of quality for survival, brand for development and customer's demand, welcome new and old customers to visit our factory for guidance.

FAQ

Q1. Can only samples be produced? A1. Yes

Q2. What is the accuracy of the products processed by the drawings?

A2. Different

equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,

electroplating, etc.

Q2. What is the accuracy of the products processed by the drawings?

A2. Different

equipment has different accuracy, generally between 0.05-0.1

Q3. What craftsmanship do you have for processing accessories?

A3.According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q4. What are your processing equipment?

A4. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine,extruder, molding machine

Q5. Can you help assembling the product after it is made?

A5. It's okay

Q6. What certifications or qualifications does your company have?

A6. Our company’s certificates are: ISO, ROHS, product patent certificates, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. It is ok. Surface treatment: spray paint, silk screen,

electroplating, etc.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices