Машина для упаковки готовых медведей, конфет, дойпаков, машина для упаковки картофельных чипсов на молнии

- Category: Industrial Machinery >>>

- Supplier: ZHEJIANG LEADTOP PHARMACEUTICAL MACHINERY CO. LTD

Share on (1600711194849):

Product Overview

Description

Simple Description

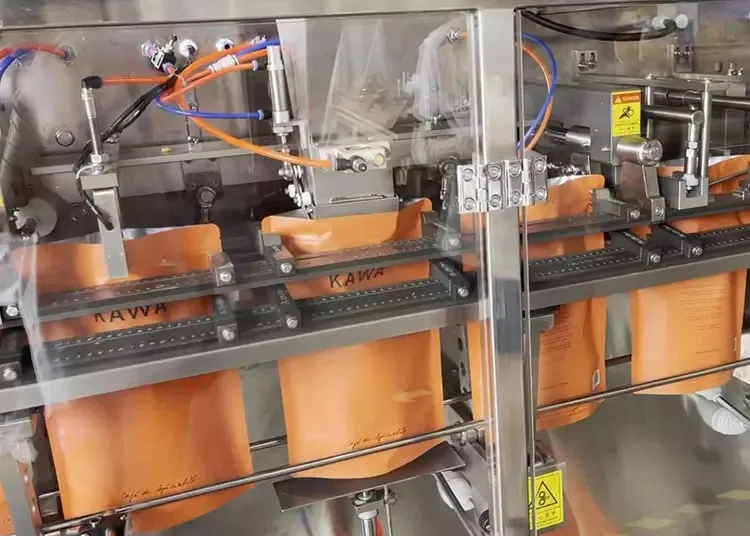

Horizontal pre-made pouch automatic packing machines series produced by our company adopted international advanced technology and derives from European classical packing machine. With blend of current packing technology, reasonable design and stable running, it is able to pack various sizes of stand-up and flat pouches. Equipped with flexible processing unit, it can automatically complete pouch forming, feeding, measuring, filling, sealing, date printing, nitrogen filling, counting, finished product delivery. Premade pouch packing series is the most optimum choice to realize economic and reasonable packing.

Features

1. Horizontal single axis driven easy for maintenance & clean

2. PLC+Touch screen for convenient opeartions.

3. If pouch not full open, no fill, no seal.

4. With combination scale, auger filler, pump filler for various product. Combination accuracy weighing, collect hopper for increase speed.

5. Servo driven powder filling, dust collector for proof powder. Servo driven single direction pump filling, proof liquid leak.

Main Technical Data

Model | HorizonTop--210 | HorizonTop--250 | HorizonTop--360 | HorizonTop--500 |

Speed | 30-50 bags/min | 30-45 bags/min | 15-35 bags/min | 3-15 bags/min |

Accuracy | ± 1.5% | ± 1.5% | ± 1.5% | ± 1.5% |

Bag width | 55-200mm | 80-250mm | 120-350mm | 120-400mm |

Bag height | 100-280mm | 100-280mm | 100-280mm | 150-500mm |

Max packaging capacity | 1-5kg | 1-5kg | 1-5kg | 1-15kg |

Power | 4kw | 4kw | 4kw | 4kw |

Gas consumption | 0.6m3/min | 0.6m3/min | 0.6m3/min | 0.6m3/min |

Air pressure value | 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa |

Weight | 1450kg | 1700kg | 2200kg | 800kg |

Size(mm) | 2900*1000*1390 | 3500*1000*1390 | 3900*1000*1390 | 2300*1000*1390 |

Warranty | 5 years | 5 years | 5 years | 5 years |

Details Images

Scale

Each adjustment station has a scale, so that the size can be adjusted quickly when filling bags of different specifications.

Food grade 304 stainless steel and Pharmaceutical grade painting

- The main parts are made of food grade 304 stainless steel, corrosion-resistant and rust free.

- The painting of the whole rack reaches the drug grade.

- The painting of the whole rack reaches the drug grade.

Dual Filling Station

- Reduce filling time by half, and improved filling accuracy.

- Can filling 2 products simultaneously

- Can filling 2 products simultaneously

Dividing box

- Indexing box running spindle, vibration only 3 microns, almost no vibration.

- The noise is low when the machine is running at high speed.

- The noise is low when the machine is running at high speed.

LED lights

There is an LED light on the back, so we can see it more clearly during maintenance.

Waterproof trough

There is a waterproof trough on the back, so we can wash the whole body directly with water.

Products

Filling Range

- Horizontal pre-made pouch automatic packaging machine is suitable for filling different products such as powder, granule, candy, tablets, liquid, viscous liquid, cream etc.

- It is applied to a wide range of packages, such as pre-made Pouch, stand up pouch, zipper pouch, spouted pouch, and shaped pouch etc.Up to 15kg can be filled

-LTPM CHINA professional team will provide different solutions for different products. Every one of your products will have its optional solution.

- Horizontal pre-made pouch automatic packaging machine is suitable for filling different products such as powder, granule, candy, tablets, liquid, viscous liquid, cream etc.

- It is applied to a wide range of packages, such as pre-made Pouch, stand up pouch, zipper pouch, spouted pouch, and shaped pouch etc.Up to 15kg can be filled

-LTPM CHINA professional team will provide different solutions for different products. Every one of your products will have its optional solution.

Difference

1. The horizontal pouch packing machine has a wide range of size adjustment. Especially when making big pouch, it can be customized accordingly, and the pouch width can be 500mm.

The pouch width of vertical rotary pouch packing machine model 200 and model 300 is only 200mm and 300mm.

2. The horizontal pouch packing machine runs horizontally, with faster speed.

The production capacity WITH suitable size can be DOUBLE---TWO FILLING OF TWO POUCH AT THE SAME TIME. The vertical rotary pouch packing machine stabilizes the speed from 35 - 40 pcs/min due to centrifugal force. In addition, when loading a large dose, the speed will be slower due to centrifugal force.

3. All the transmission mechanism and mechanical structure of the horizontal pouch packing machine are behind the machine, which is easier to clean and more in line with the requirements of clean production.

The vertical rotary pouch packing machine is mechanically driven at the bottom. If powder or liquid is produced, it is not easy to clean and corrode in case of leakage.

Company Profile

Our Company

Zhejiang LeadTop Pharmaceutical Machinery Co.,ltd well known as LTPM China. Since year 1996, we are start manufacturing Oral Solid Dosage Pharmaceutical Machinery includes Mixing Machine, Drying Equipment, granulation line, IBC Bin and Bin Washing Machine. As year passed, LTPM China absorb advanced domestic and abroad technology, we export machinery to more than 30 countries all over the world. LTPM China is considered one of the major Pharmaceutical Machinery Supplier and exporter in China mainland. Professional,Enthusiasm, Service and Team Work has been always our value to create for our Staff and customers. As year 2012 we position our value as “A Pharma Machinery Division, For A Better Life”, creating a Win-Win Platform for our clients and staff for a better life is our vision.

Our Certificates

ISO, CE, SGS, BV Certified Company.

Our Machinery Manufacturing Workshop

Imported CNC Machining Centre makes all parts process accurate. Own R&D team with more than 20 years engineering expereince, can customize the equipment and packaging line to your satisfaction.

Our Machinery Manufacturing Workshop

Imported CNC Machining Centre makes all parts process accurate. Own R&D team with more than 20 years engineering expereince, can customize the equipment and packaging line to your satisfaction.

Professional Business Team

Warm, professional business team, careful response to your inquiry, timely response rate of more than 93%, higher than the average level of the industry.

Packing & Shipping

All machine delivery with anti rust spray, film wrapping and Sea shipping affordable wooden box.

FAQ

Q: What price terms you offer?

A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request.

Q: What payment terms you take?

A: TT, LC, other terms are also workable.

Q: Will you help with installation and stuff training?

A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day.

Q: How can I visit your factory?

A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you!

Any other doubts about our machine, please feel easy to contact with us.

A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request.

Q: What payment terms you take?

A: TT, LC, other terms are also workable.

Q: Will you help with installation and stuff training?

A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day.

Q: How can I visit your factory?

A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you!

Any other doubts about our machine, please feel easy to contact with us.

We Recommend

banana chips drying machine fruit drying machine food dryer machine

US $139.00-$150.00

Slushie machine SC-2

US $100.00-$1000

New Arrivals

New products from manufacturers at wholesale prices