mould release agent for metal made in China

- Category: >>>

- Supplier: Guangzhou Luode Chemical Technology And Trade Co. Ltd.

Share on (1600713504433):

Product Overview

Description

Recommend Products

Contact us today to learn more about how we can help!

phone:+86 13500020933

phone:+86 13500020933

whatsapp/wechat:13500020933

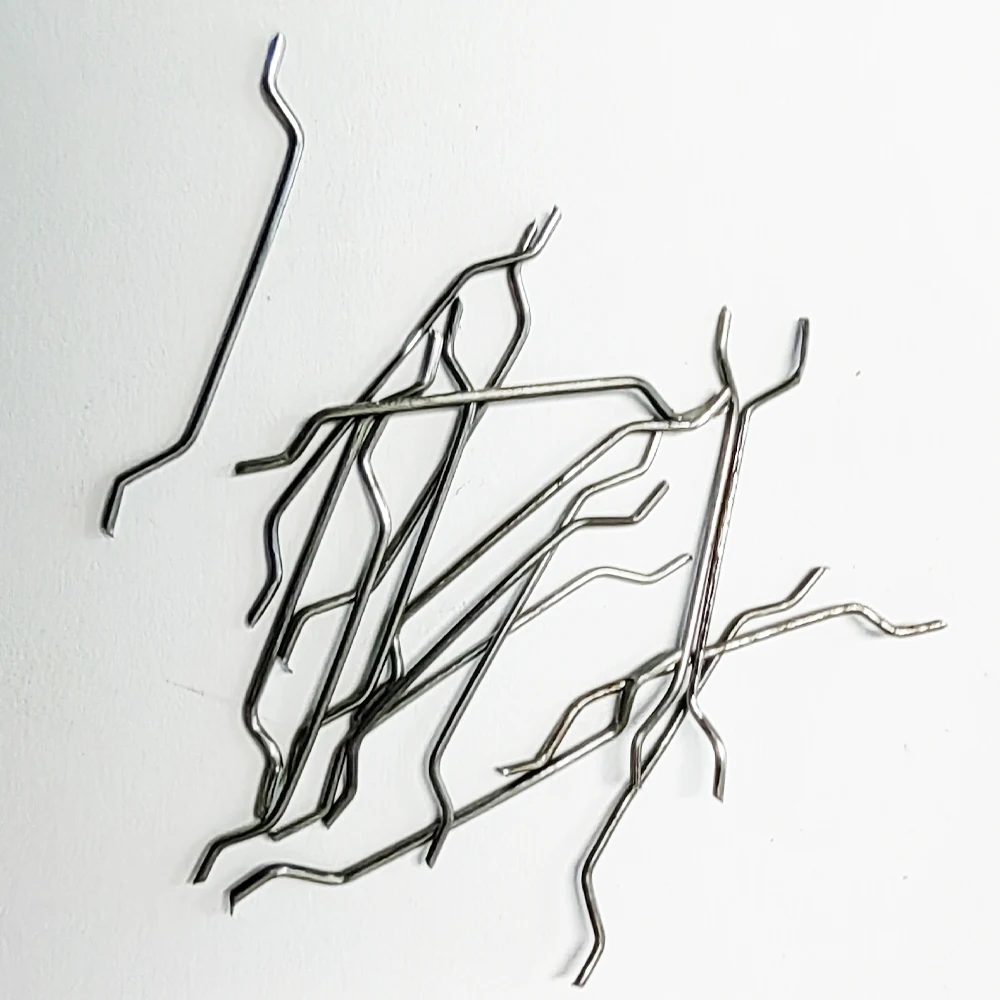

Product Name | Die-casting Release Agent | Die-casting release agent / mold lubricant | ||||

Model | LD-TW-710Y | LD-TW-230 | ||||

Material | Base oil, synthetic fatty acid ester, release additive | Nonionic surfactant, release additive, heat stabilizer, pure water | ||||

Color | Colorless to yellow transparent liquid | Milky liquid | ||||

Function | It is applied to die casting and demoulding, so that the surface of the object is easy to separate, smooth and clean. It is used for casting and demoulding of ferrous metals such as cast iron alloys. It can make the production surface smooth and shiny, effectively prolong the service life of the mold, and not pollute the metal. | It is applied to die casting and demolding, so that the surface of the object is easy to separate, smooth and clean. It is suitable for demolding aluminum, magnesium and other metals and alloys, especially thin parts such as mobile phone middle plate. | ||||

Features | 1. Excellent release performance, keep the surface of the mold (cavity) clean 2. From high temperature to low temperature, wide range of use, good use effect 3. Good adhesion, excellent use effect for large and complex parts, no bubbles and defects, full contour of parts 4. Not easy to flash fire, safe to use. | 1. This product is water-soluble, has no waste liquid (waste gas) discharge, does not contain any flammable and harmful substances, and meets the requirements of environmental protection, health and safety. 2. Excellent release performance, keep the mold (cavity) surface clean and parts bright. 3. Good adhesion, excellent high temperature resistance, wide application range and good application effect. 4. It is easy to clean without contamination and does not affect the subsequent coating process. | ||||

Dimethyl Silicone Oil Emulsion Silicone Emulsion polish mould release agent

Products Description

Products:

Metalworking fluids/oil products such as

Cleaners/Rust inhibitors/Cutting fluids/Stamping oils/Demoulding agents/

Hydraulic oils/guideway oils etc.

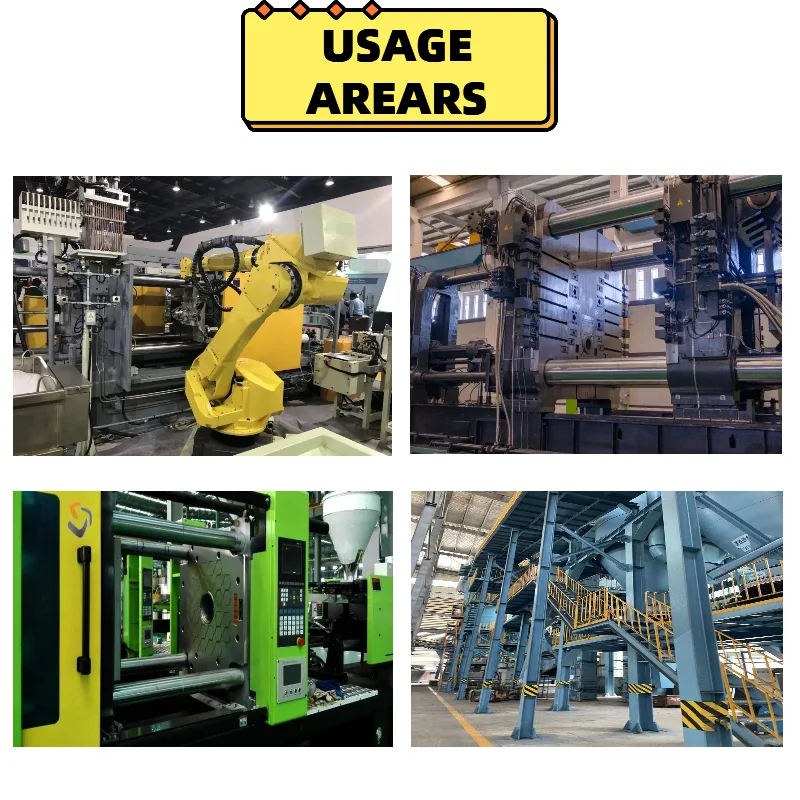

Application areas:

New energy vehicles, refrigeration, aviation, machining, military, electronics industry, etc.

Company Profile

Guangzhou Luode Chemical Tech and Trade Co. Ltd. based in Guangdong, China, start from 1995.

There are total about 150-500 people in our office.Our factory covers an area of 33,000 ㎡.Our production capacity is more than 20,000 tonnes/year.

We are a long-term supplier to global 500 companies such as Panasonic, Midea, Gree, etc.

OEM and ODM are always welcome.

Mixing workshop

Finished workshop(GREE Exclusive)

Lab equipment

R&D Team

Technical cooperation with the Chinese Academy of Sciences

R&D lab

Panasonic's excellent suppliers

20 years of using our products

20 years of using our products

office

VOLUNTEER SERVICE

Our partners

We are a long-term supplier to global 500 companies.

and looking forward to establish more cooperation in the global market.

Certifications

Perfect production management system, complete qualification (REAC,ROHS,ISO9001, ISO45001, ISO14001.etc), quality assurance,eco-friendly

REACH

ROHS

ISO 14001

ISO 45001

Panasonic's excellent suppliers

National High-tech Enterprise

Production Process

1 Research&Develop

2 Product Test

3. Manufacture

4. Storage

5. Loading&Transport

Packing & Delivery

Our products are packaged safely and securely and are available in 20L, 30L, 200L, 1 tonne and other sizes .

According to the different production needs of our customers, we also support custom specifications.

We will wrap it in strapping film and install wooden boards to protect it.

Contact us today to learn more about how we can help!

phone:+86 13500020933

phone:+86 13500020933

whatsapp/wechat:13500020933

jerry cans

20L(5 gal)/30L(8 gal)

drums

20L(5 gal)/200L(55 gal)

IBC

1ton

We have delivery trucks, also have regular cooperation with well-known logistics companies.

FAQ

1. who are we?

We based in Guangdong, China, start from 1995,there are total about 150-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before https://gzluode.en.alibaba.com/contactinfo.html mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cutting fluid, grinding fluid, blanking oil, mold release agent, plunger oil;

and metal surface treatment agents: cleaning agent,rust inhibitor and etc.

4. why should you buy from us not from other suppliers?

● 27-year-old professional OEM/ODM Chemical factory covers area of 33,000 square meters and over 150 professional employees,60% of which are technical personnel.

We based in Guangdong, China, start from 1995,there are total about 150-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before https://gzluode.en.alibaba.com/contactinfo.html mass production;

Always final Inspection before shipment;

3.what can you buy from us?

cutting fluid, grinding fluid, blanking oil, mold release agent, plunger oil;

and metal surface treatment agents: cleaning agent,rust inhibitor and etc.

4. why should you buy from us not from other suppliers?

● 27-year-old professional OEM/ODM Chemical factory covers area of 33,000 square meters and over 150 professional employees,60% of which are technical personnel.

● Our environmental and quality certificates are complete.

● Our products have been tested by global 500 companies (Panasonic, Midea, Gree etc. in Japan) who have been using our products for over 20 years.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union,Cash;

Language Spoken:English,Chinese

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,MoneyGram,Western Union,Cash;

Language Spoken:English,Chinese

We Recommend

New Arrivals

New products from manufacturers at wholesale prices